![]()

![]()

![]()

![]()

![]() The

The![]() Bradford

Bradford![]()

![]()

![]() White

White

DEFENDER

DEFENDER

Safety System®

TEMPERATURE SENSOR TESTING

If Control has gone into lockout due to excessive tank temperature (four flash, three second pause) reset control by rotating gas control knob to “OFF” position and wait a minimum of (5) minutes. Then follow lighting instructions and return gas control

knob to desired setpoint.

SERVICE PROCEDURE

Gas Control

Testing, Disassembly & Replacement (Honeywell)

CAUTION

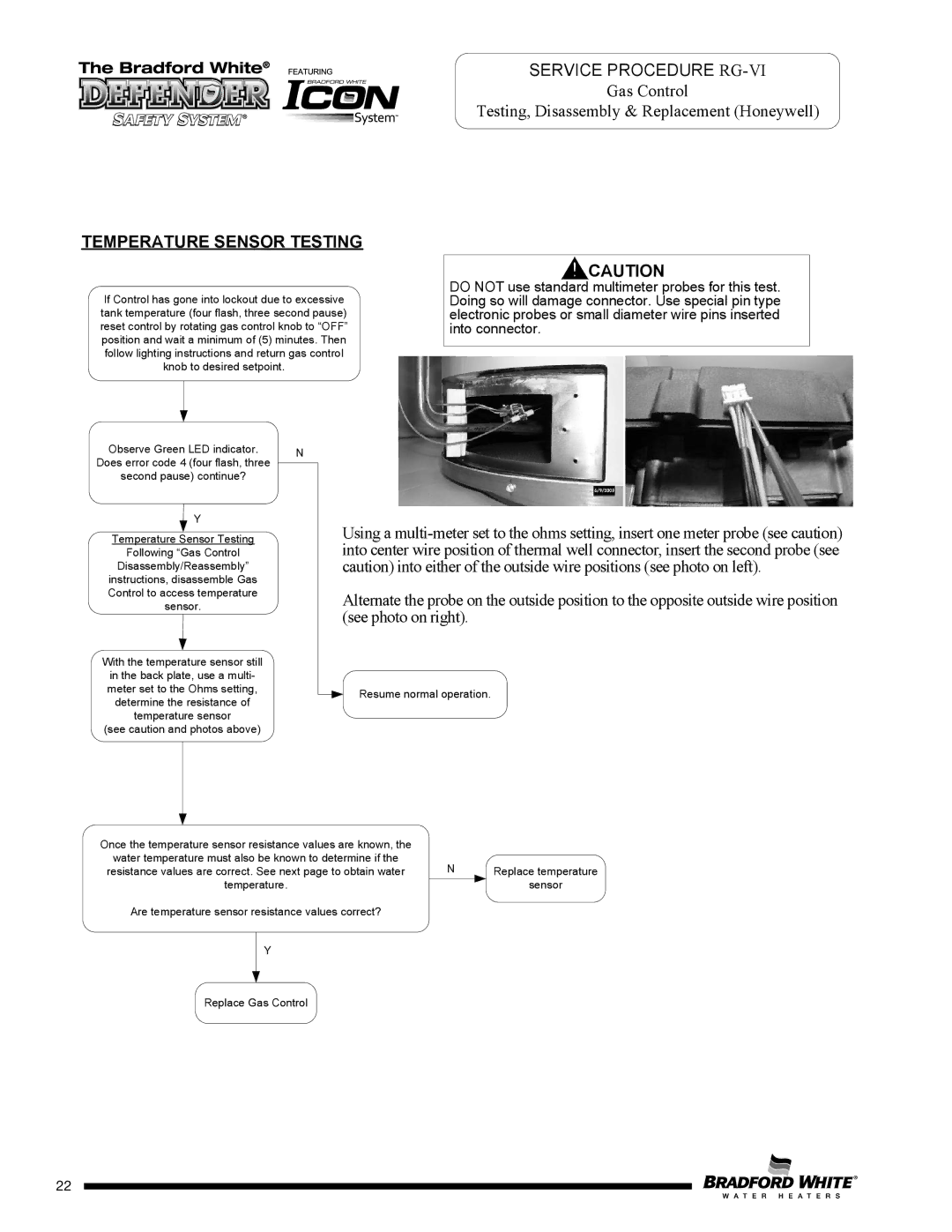

DO NOT use standard multimeter probes for this test. Doing so will damage connector. Use special pin type electronic probes or small diameter wire pins inserted into connector.

Observe Green LED indicator. | N | |||

Does error code 4 (four flash, three | ||||

| ||||

| second pause) continue? |

| ||

| Y |

| ||

Temperature Sensor Testing |

| |||

| Following “Gas Control |

|

| |

| Disassembly/Reassembly” |

| ||

instructions, disassemble Gas |

| |||

Control to access temperature |

| |||

| sensor. |

| ||

With the temperature sensor still |

| |||

in the back plate, use a multi- |

| |||

meter set to the Ohms setting, |

| |||

| determine the resistance of |

| ||

| temperature sensor |

| ||

(see caution and photos above) |

| |||

Using a

Alternate the probe on the outside position to the opposite outside wire position (see photo on right).

Resume normal operation.

Once the temperature sensor resistance values are known, the |

|

| |

water temperature must also be known to determine if the | N |

| |

resistance values are correct. See next page to obtain water | Replace temperature | ||

temperature. |

| sensor | |

Are temperature sensor resistance values correct? |

|

| |

| Y |

|

|

|

|

| |

|

|

|

|

Replace Gas Control |

|

| |

22

22