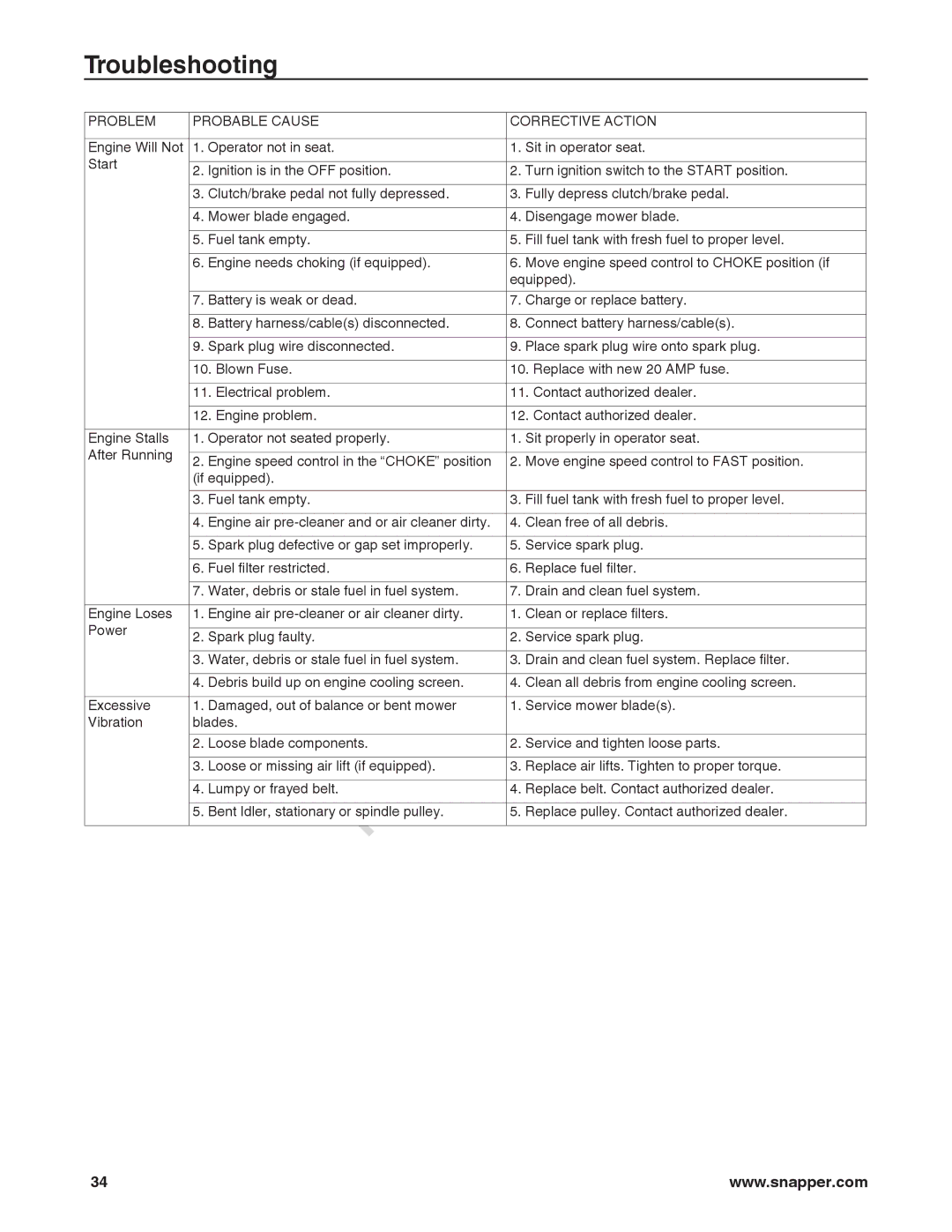

Troubleshooting

|

|

| ||

PROBLEM | PROBABLE CAUSE | CORRECTIVE ACTION | ||

Engine Will Not | 1. Operator not in seat. | 1. | Sit in operator seat. | |

Start |

|

|

| |

2. Ignition is in the OFF position. | 2. | Turn ignition switch to the START position. | ||

| 3. | Clutch/brake pedal not fully depressed. | 3. | Fully depress clutch/brake pedal. |

| 4. | Mower blade engaged. | 4. | Disengage mower blade. |

| 5. | Fuel tank empty. | 5. | Fill fuel tank with fresh fuel to proper level. |

| 6. | Engine needs choking (if equipped). | 6. | Move engine speed control to CHOKE position (if |

|

|

| equipped). | |

| 7. | Battery is weak or dead. | 7. | Charge or replace battery. |

| 8. | Battery harness/cable(s) disconnected. | 8. | Connect battery harness/cable(s). |

| 9. | Spark plug wire disconnected. | 9. | Place spark plug wire onto spark plug. |

| 10. Blown Fuse. | 10. Replace with new 20 AMP fuse. | ||

| 11. Electrical problem. | 11. Contact authorized dealer. | ||

| 12. Engine problem. | 12. Contact authorized dealer. | ||

Engine Stalls | 1. Operator not seated properly. | 1. | Sit properly in operator seat. | |

After Running |

|

|

| |

2. Engine speed control in the “CHOKE” position | 2. | Move engine speed control to FAST position. | ||

| (if equipped). |

|

| |

| 3. | Fuel tank empty. | 3. | Fill fuel tank with fresh fuel to proper level. |

| 4. | Engine air | 4. | Clean free of all debris. |

| 5. | Spark plug defective or gap set improperly. | 5. | Service spark plug. |

| 6. | Fuel filter restricted. | 6. | Replace fuel filter. |

| 7. | Water, debris or stale fuel in fuel system. | 7. | Drain and clean fuel system. |

Engine Loses | 1. Engine air | 1. | Clean or replace filters. | |

Power |

|

|

| |

2. Spark plug faulty. | 2. | Service spark plug. | ||

| 3. | Water, debris or stale fuel in fuel system. | 3. | Drain and clean fuel system. Replace filter. |

| 4. | Debris build up on engine cooling screen. | 4. | Clean all debris from engine cooling screen. |

Excessive | 1. Damaged, out of balance or bent mower | 1. | Service mower blade(s). | |

Vibration | blades. |

|

| |

| 2. | Loose blade components. | 2. | Service and tighten loose parts. |

| 3. | Loose or missing air lift (if equipped). | 3. | Replace air lifts. Tighten to proper torque. |

| 4. | Lumpy or frayed belt. | 4. | Replace belt. Contact authorized dealer. |

| 5. | Bent Idler, stationary or spindle pulley. | 5. | Replace pulley. Contact authorized dealer. |

34 | www.snapper.com |