SEWING BUTTONHOLES AND BUTTONS

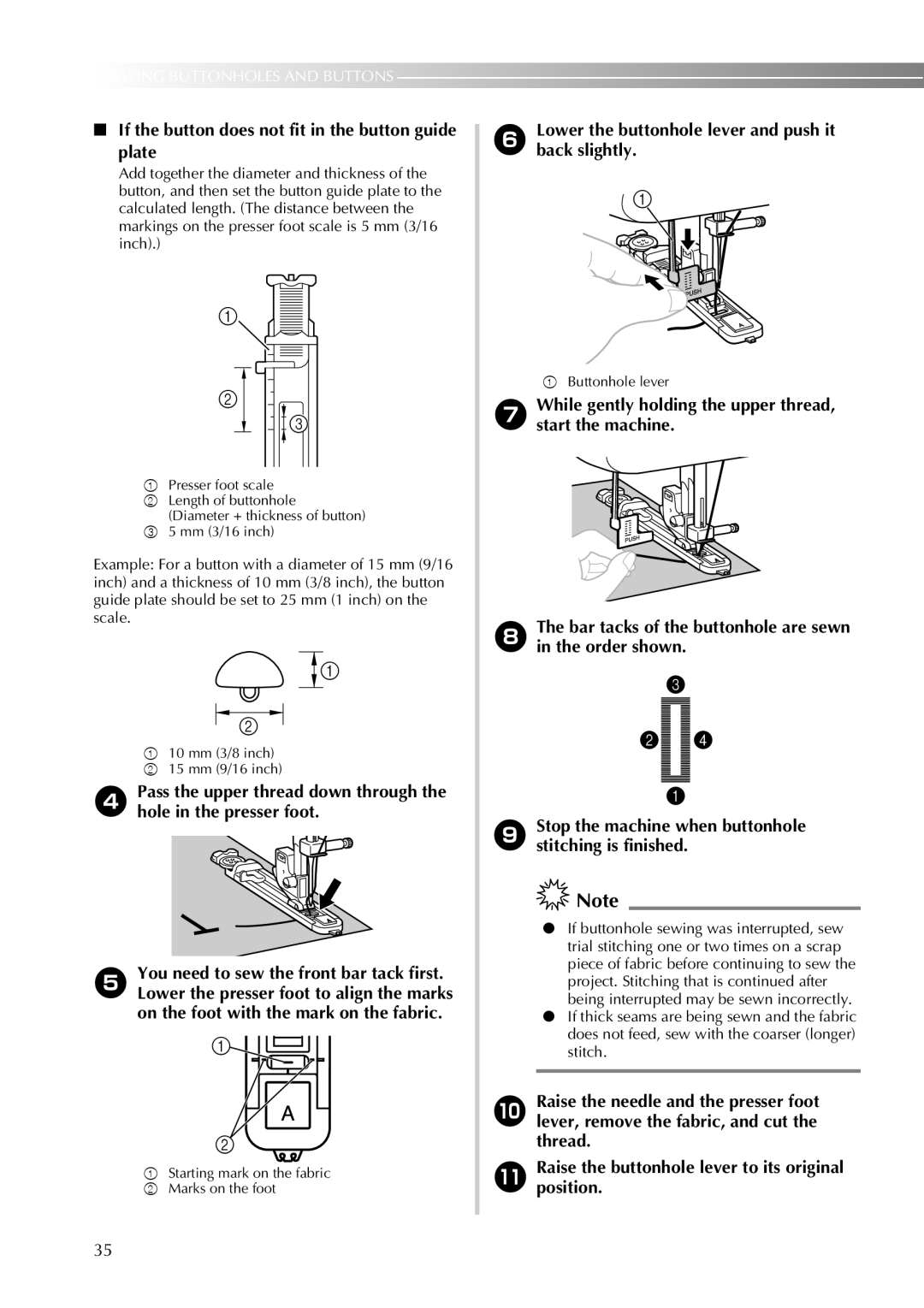

■If the button does not fit in the button guide plate

Add together the diameter and thickness of the button, and then set the button guide plate to the calculated length. (The distance between the markings on the presser foot scale is 5 mm (3/16 inch).)

1

2

![]()

![]() 3

3

1Presser foot scale

2Length of buttonhole

(Diameter + thickness of button)

35 mm (3/16 inch)

Example: For a button with a diameter of 15 mm (9/16 inch) and a thickness of 10 mm (3/8 inch), the button guide plate should be set to 25 mm (1 inch) on the scale.

1

2

110 mm (3/8 inch)

215 mm (9/16 inch)

4Pass the upper thread down through the hole in the presser foot.

5 You need to sew the front bar tack first.

Lower the presser foot to align the marks on the foot with the mark on the fabric.

1

2

1Starting mark on the fabric

2Marks on the foot

6Lower the buttonhole lever and push it back slightly.

![]() 1

1

1Buttonhole lever

7While gently holding the upper thread, start the machine.

8The bar tacks of the buttonhole are sewn in the order shown.

3

2![]()

![]() 4

4

1

9Stop the machine when buttonhole stitching is finished.

![]()

![]()

![]() Note

Note

●If buttonhole sewing was interrupted, sew trial stitching one or two times on a scrap piece of fabric before continuing to sew the project. Stitching that is continued after being interrupted may be sewn incorrectly.

●If thick seams are being sewn and the fabric does not feed, sew with the coarser (longer) stitch.

0Raise the needle and the presser foot lever, remove the fabric, and cut the thread.

aRaiseposition.the buttonhole lever to its original

35