Floor Preparation and Installation

Installation instructions are provided for

Warning! A level

Layout of the Floor

Check the floor plan of the

is furnished with each

the |

|

base of the box. If the |

|

next to an existing wall a 2" clearance should |

|

be allowed for surface irregularity. |

|

‘Builders Level’ per instructions. Take readings at |

|

selected intervals on a story pole to determine the |

|

highest point of floor assembly. Mark the high point |

|

and shim to this level. | Shim |

Level

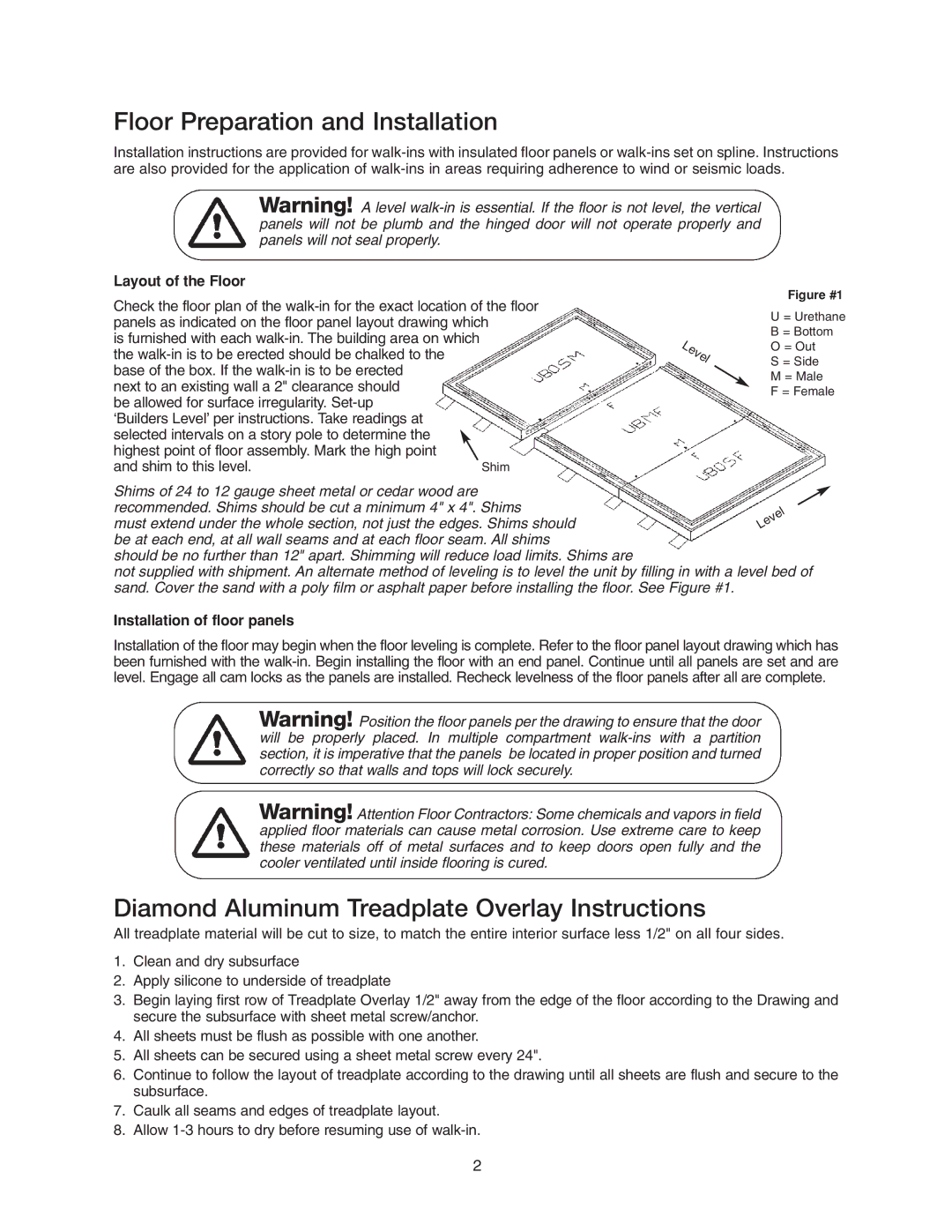

Figure #1

U = Urethane

B = Bottom

O = Out

S = Side

M = Male

F = Female

Shims of 24 to 12 gauge sheet metal or cedar wood are |

|

recommended. Shims should be cut a minimum 4" x 4". Shims | Level |

must extend under the whole section, not just the edges. Shims should | |

be at each end, at all wall seams and at each floor seam. All shims |

|

should be no further than 12" apart. Shimming will reduce load limits. Shims are |

|

not supplied with shipment. An alternate method of leveling is to level the unit by filling in with a level bed of sand. Cover the sand with a poly film or asphalt paper before installing the floor. See Figure #1.

Installation of floor panels

Installation of the floor may begin when the floor leveling is complete. Refer to the floor panel layout drawing which has been furnished with the

Warning! Position the floor panels per the drawing to ensure that the door will be properly placed. In multiple compartment

Warning! Attention Floor Contractors: Some chemicals and vapors in field applied floor materials can cause metal corrosion. Use extreme care to keep these materials off of metal surfaces and to keep doors open fully and the cooler ventilated until inside flooring is cured.

Diamond Aluminum Treadplate Overlay Instructions

All treadplate material will be cut to size, to match the entire interior surface less 1/2" on all four sides.

1.Clean and dry subsurface

2.Apply silicone to underside of treadplate

3.Begin laying first row of Treadplate Overlay 1/2" away from the edge of the floor according to the Drawing and secure the subsurface with sheet metal screw/anchor.

4.All sheets must be flush as possible with one another.

5.All sheets can be secured using a sheet metal screw every 24".

6.Continue to follow the layout of treadplate according to the drawing until all sheets are flush and secure to the subsurface.

7.Caulk all seams and edges of treadplate layout.

8.Allow

2