524A AIR-HANDLING Units

FEATURES/BENEFITS

Table of Contents

Sound LEVELS, dB 569D/576C/566D,E

Estimated Sound Power Levels Lw 524A072-300

ARI* Capacity Ratings

Options and Accessories

Options and Accessories

566D, 566E, 569D, 569F, 576C FACTORY-INSTALLED Options

FIELD-INSTALLED Accessories

Commercial Programmable Non-Programmable Thermostat

Options and Accessories

524A-B, C FACTORY-INSTALLED Options

524A with Economizer 524A with Condensate Trap

524A with Discharge Plenum, Return Grille, and Subbase

524A with Hot Water or Steam Coil

III Determine Sizes of Liquid and Suction Lines

Selection Procedure

IV Determine FAN RPM and BHP Brake Horsepower

II Select Condensing Unit AIR-HANDLER Combination

Operating Sequences

Controls

569D090, 208/230-3-360 and 460-3-60 Units

Typical Wiring Schematics

576C120, 208/230-3-60 and 460-3-60 Units

Typical Wiring Schematics

Model Number Nomenclature

Unit

Physical Data

569D072-120, 576C120, 569F120 Units

569D072-120, 576C120

Dimensions

569D072

Dimensions

Condensing Unit Ratings

Performance Data

SHC

Performance Data

Combination Ratings

569D072/524A-C072 with HIGH-CAPACITY 4-ROW Coil

2400 3000 3750 Condenser

Combination Ratings

569D072/524A-C090 with HIGH-CAPACITY 4-ROW Coil

569D090/524A-B072 with Standard 3-ROW Coil

Unit 569D090

569D090/524A-C072 with HIGH-CAPACITY 4-ROW Coil

Temp F

569D090/524A-B090 with Standard 3-ROW Coil

569D090/524A-C090 with HIGH-CAPACITY 4-ROW Coil

2205 3000 3750 Condenser

569D120/524A-B120 with Standard 3-ROW Coil

Unit 569D120

569D120/524A-C120 with HIGH-CAPACITY 4-ROW Coil

3000 4000 5000 Condenser

569D120/524A-B150 with Standard 3-ROW Coil

569D120/524A-C150 with HIGH-CAPACITY 4-ROW Coil

3750 5000 6250 Condenser

576C120/524A-B120 with Standard 3-ROW Coil

Unit 576C120

576C120/524A-C120 with HIGH-CAPACITY 4-ROW Coil

576C120/524A-B150 with Standard 3-ROW Coil

576C120/524A-C150 with HIGH-CAPACITY 4-ROW Coil

569F120/524A-B120 with Standard 3-ROW Coil

Unit 569F120

569F120/524A-C120 with HIGH-CAPACITY 4-ROW Coil

569F120/524A-B150 with Standard 3-ROW Coil

569F120/524A-C150 with HIGH-CAPACITY 4-ROW Coil

Electrical Data

Refrigerant Piping Sizes

Operating Limits Minimum OUTDOOR-AIR Operating Temperature

Application Data 569D072-120, 576C090-120, 569F120

Maximum Refrigerant Charge

Rooftop Installation 569D072-120, 576C120

Typical Piping and Wiring

Part 2 Products

Guide Specifications 569D072-120, 576C120

Commercial AIR-COOLED Condensing Units

Part 1 General

Guide Specifications 569D072-120, 576C120

Guide Specifications 569F120

Guide Specifications 569F120

566D E X 150

566D150-240 Units

566E150-240 Units

Physical Data

Dimensions

Dimensions

Aluminum Coil Unit

566D150-240, 566E150-240

Air Temperature Entering Condenser F 100 105 115

566D150/524A-B150 with Standard 3-ROW Coil

Unit 566D150

566D150/524A-C150 with High Capacity 4-ROW Coil

Edb

566D150/524A-B180 with Standard 3-ROW Coil

566D150/524A-C180 with High Capacity 4-ROW Coil

4500 6000 7500 Condenser

566D180/524A-B180 with Standard 3-ROW Coil

Unit 566D180

566D180/524A-C180 with HIGH-CAPACITY 4-ROW Coil

566D180/524A-B240 with Standard 3-ROW Coil

566D180/524A-C240 with HIGH-CAPACITY 4-ROW Coil

000 10,000 Condenser

566D240/524A-B300 with Standard 3-ROW Coil

Unit 566D240

566D240/524A-C300 with HIGH-CAPACITY 4-ROW Coil

500 10,000 12,500 Condenser

566E150/524A-B120 with Standard 3-ROW Coil

Unit 566E150

566E150/524A-C120 with HIGH-CAPACITY 4-ROW Coil

566E150/524A-B150 with Standard 3-ROW Coil

566E150/524A-C150 with HIGH-CAPACITY 4-ROW Coil

566E150/524A-B180 with Standard 3-ROW Coil

566E150/524A-C180 with HIGH-CAPACITY 4-ROW Coil

566E180/524A-B150 with Standard 3-ROW Coil

Unit 566E180

566E180/524A-C150 with HIGH-CAPACITY 4-ROW Coil

566E180/524A-B180 with Standard 3-ROW Coil

566E180/524A-C180 with HIGH-CAPACITY 4-ROW Coil

566E180/524A-B240 with Standard 3-ROW Coil

566E180/524A-C240 with HIGH-CAPACITY 4-ROW Coil

566E240/524A-B240 with Standard 3-ROW Coil

Unit 566E240

566E240/524A-C240 with HIGH-CAPACITY 4-ROW Coil

566E240/524A-B300 with Standard 3-ROW Coil

566E240/524A-C300 with HIGH-CAPACITY 4-ROW Coil

Nominal Voltage Compressor

Operating Limits

Minimum OUTDOOR-AIR Operating Temperature 566D150-240 Units

Minimum OUTDOOR-AIR Operating Temperature 566E150-240 Units

Application Data 566D150-240, 566E150-240

Suction Line Piping

Face-Split Coil Suction Liquid Line Piping

Refrigerant Piping Sizes Double Suction Risers

566D, 566E150-240

Multiple Condensing Unit Arrangements

Rooftop Installation 566D150-240

Ground Level Installation 566D150-240

Typical Piping and Wiring

Guide Specifications 566D150-240, 566E150-240

Guide Specifications 566D150-240, 566E150-240

Nominal Cooling Tons 072

524A P B 120 000 GC

Voltage

Coil Option

Unit 524A

524A-B,C Units

524A-B,C072-120

Unit Unit Weight

524A-B,C150-240

B300 1020 C300 1050

524A-B,C300

Unit Airflow

524A-B FAN Performance Data 0.0-1.2 in. wg ESP

524A-B FAN Performance Data 1.4-2.4 in. wg ESP

1.2 in. wg ESP

FAN Performance Data 524A-C with High Capacity Coil

With High Capacity Coil 1.4-2.4 in. wg ESP

FAN Performance Data 524A-C

FACTORY-SUPPLIED Filter Pressure Drop

Accessory Plenum AIR Throw Data

Accessory Pressure Drop in. wg

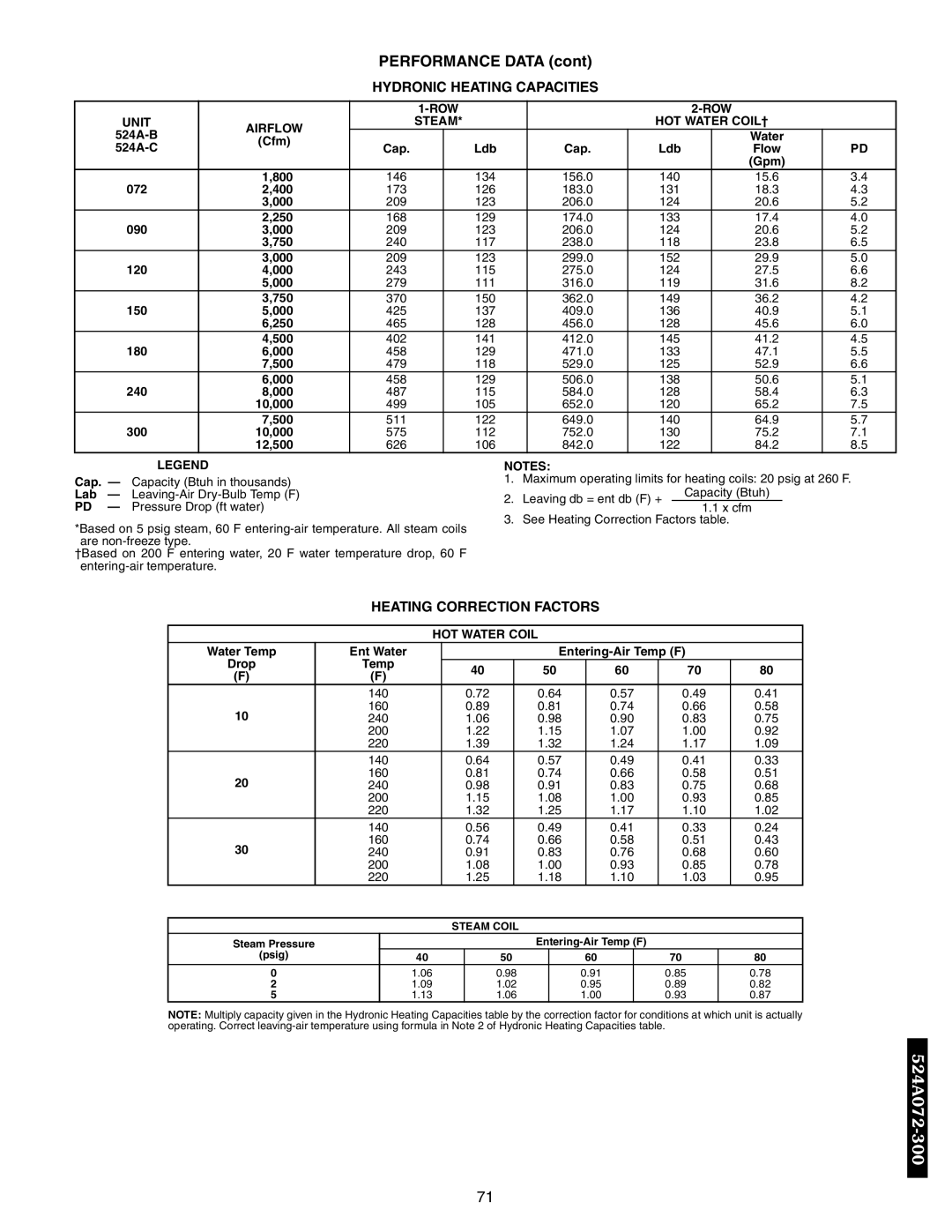

HOT Water COIL†

Hydronic Heating Capacities

Heating Correction Factors

ROW Unit Airflow

FLA Mocp

Unit Voltage FAN Motor Power Supply

524A-B,C Standard Motors

524A-B PH-Hz

FLA

Electrical Data

524A-B,C Alternate Motors

Electric Heater Data

Electric Heater Data

CAELHEAT019A00

CAELHEAT016A00

CAELHEAT017A00

CAELHEAT018A00

CAELHEAT028A00

CAELHEAT025A00

CAELHEAT026A00

CAELHEAT027A00

CAELHEAT037A00

CAELHEAT034A00

CAELHEAT035A00

CAELHEAT036A00

Standard Motor Unit Size 524A

FACTORY-INSTALLED Nozzle and Distributor Data

Application Data 524A

FAN Motor Data

Standard Drive Data

Application Data 524A

FAN Motor Data

HIGH-STATIC Drive Data

MEDIUM-STATIC Drive Data

Commercial Packaged AIR-HANDLING Unit

Guide Specifications 524A

Air Discharge Plenum

Guide Specifications 524A

Index