| 3. | Use flexible transition between rigid ductwork and unit to |

|

| prevent transmission of vibration. The transition may be |

|

| screwed or bolted to duct flanges. Use suitable gaskets to |

|

| ensure |

| 4. | All units must have |

|

| rack installed in the |

|

| Recommended sizes for filters are shown in Table 1. |

| 5. | Size all ductwork for maximum required airflow (either |

|

| heating or cooling) for unit being installed. Avoid abrupt |

|

| duct size increases or decreases or performance may be |

|

| affected. |

| 6. | Adequately insulate and weatherproof all ductwork located |

|

| outdoors. Insulate ducts passing through unconditioned |

|

| space, and use vapor barrier in accordance with latest issue |

|

| of Sheet Metal and Air Conditioning Contractors National |

|

| Association (SMACNA) and Air Conditioning Contractors |

|

| of America (ACCA) minimum installation standards for |

| ||

| heating and air conditioning systems. Secure all ducts to | |

| building structure. | |

607C | 7. | Flash, weatherproof, and |

| building structure in accordance with local codes and good | |

|

| building practices. |

Step 6 — Provide for Condensate Disposal

NOTE: Ensure that

The

If the installation requires draining the condensate water away from the unit, install a

A | C |

MAXIMUM ALLOWABLE

BDIFFERENCE in. (mm)

|

| ||||

1/4 | (6.35) | 1/4 | (6.35) | 1/4 | (6.35) |

|

|

|

|

|

|

A07925

Fig. 7 - Unit Leveling Tolerances

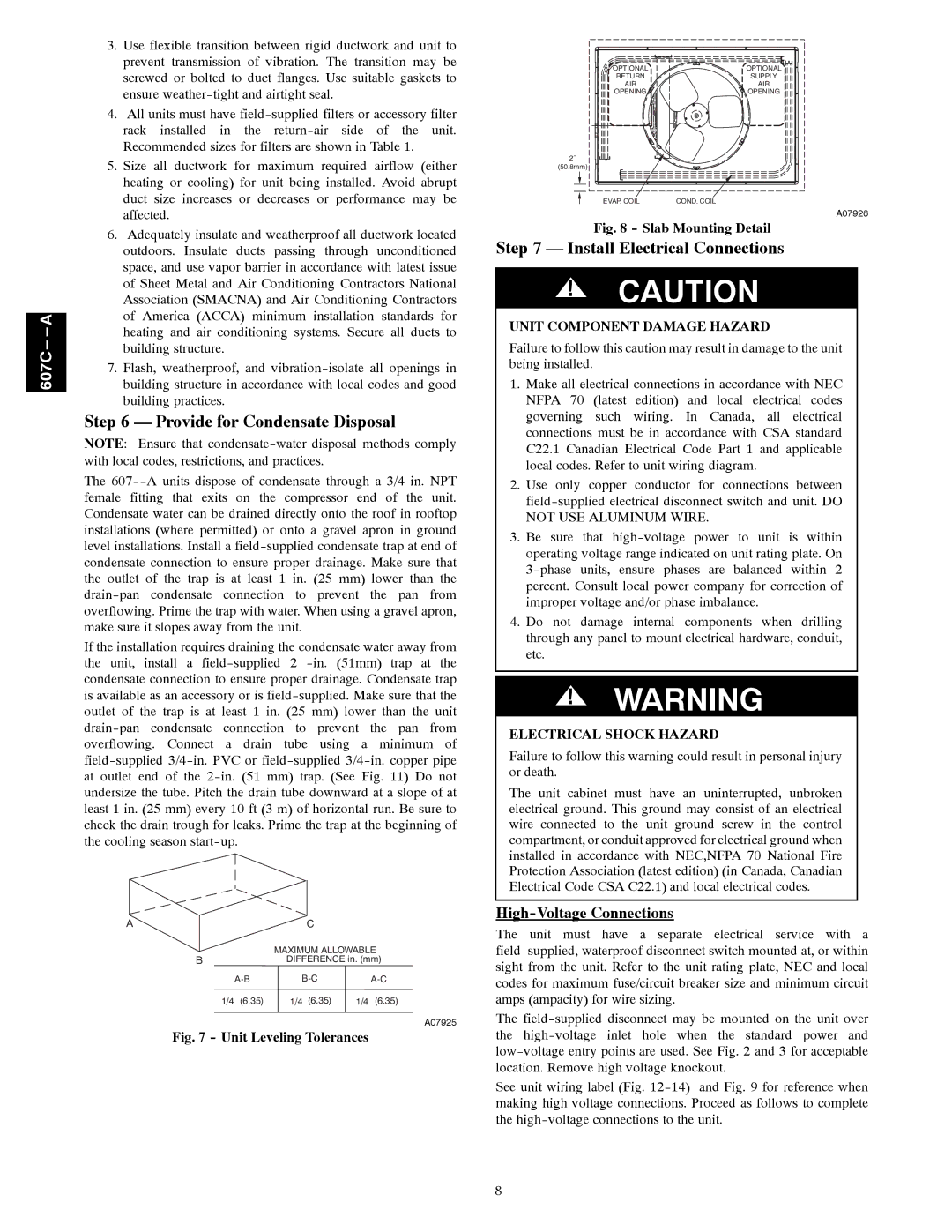

OPTIONAL | OPTIONAL |

RETURN | SUPPLY |

AIR | AIR |

OPENING | OPENING |

2˝ |

|

(50.8mm) |

|

EVAP. COIL | COND. COIL |

A07926

Fig. 8 - Slab Mounting Detail

Step 7 — Install Electrical Connections

!CAUTION

UNIT COMPONENT DAMAGE HAZARD

Failure to follow this caution may result in damage to the unit being installed.

1.Make all electrical connections in accordance with NEC NFPA 70 (latest edition) and local electrical codes governing such wiring. In Canada, all electrical connections must be in accordance with CSA standard C22.1 Canadian Electrical Code Part 1 and applicable local codes. Refer to unit wiring diagram.

2.Use only copper conductor for connections between

3.Be sure that

4.Do not damage internal components when drilling through any panel to mount electrical hardware, conduit, etc.

!WARNING

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could result in personal injury or death.

The unit cabinet must have an uninterrupted, unbroken electrical ground. This ground may consist of an electrical wire connected to the unit ground screw in the control compartment, or conduit approved for electrical ground when installed in accordance with NEC,NFPA 70 National Fire Protection Association (latest edition) (in Canada, Canadian Electrical Code CSA C22.1) and local electrical codes.

High-Voltage Connections

The unit must have a separate electrical service with a

The

See unit wiring label (Fig.

8