VI. STEP 6 — MAKE ELECTRICAL CONNECTIONS

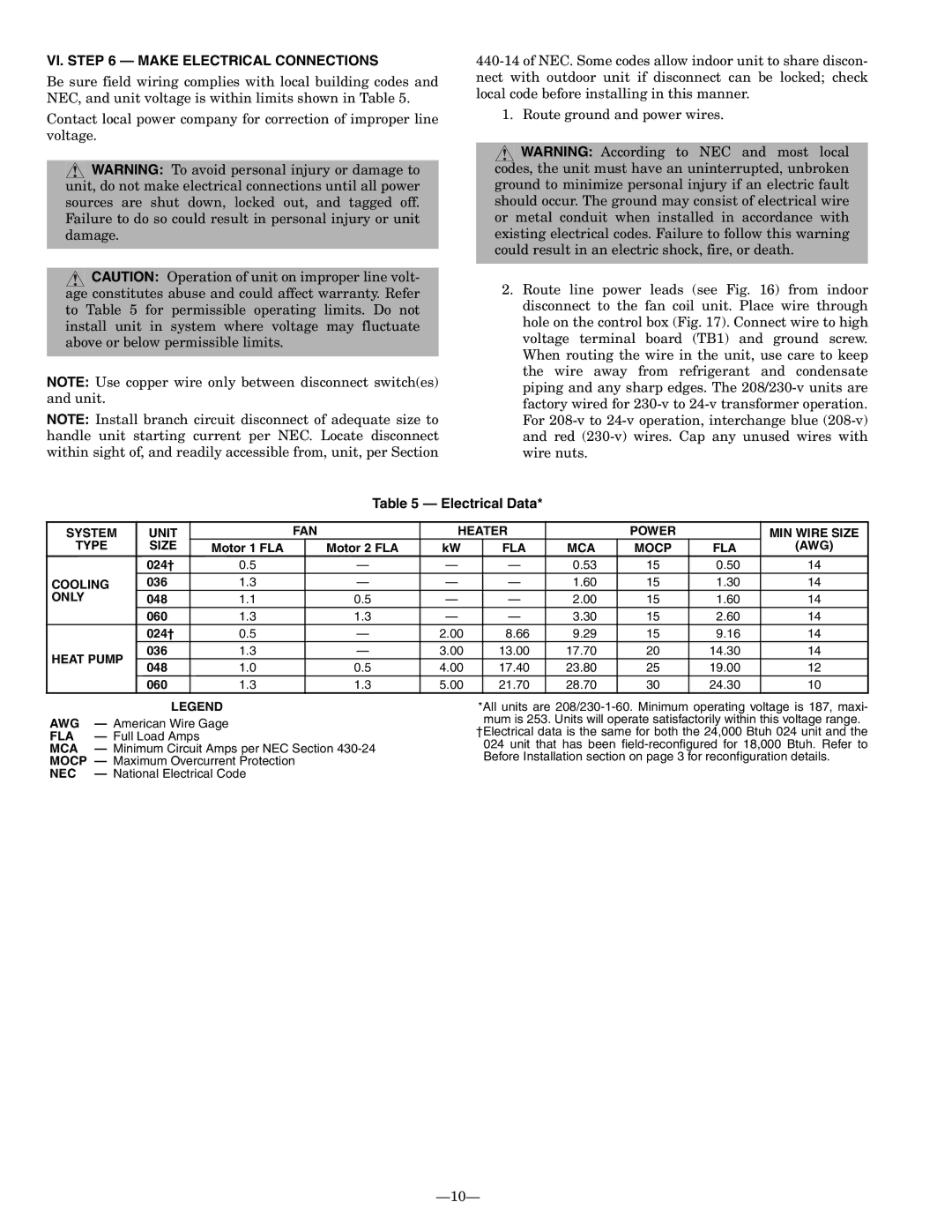

Be sure field wiring complies with local building codes and NEC, and unit voltage is within limits shown in Table 5.

Contact local power company for correction of improper line voltage.

![]() WARNING: To avoid personal injury or damage to unit, do not make electrical connections until all power sources are shut down, locked out, and tagged off. Failure to do so could result in personal injury or unit damage.

WARNING: To avoid personal injury or damage to unit, do not make electrical connections until all power sources are shut down, locked out, and tagged off. Failure to do so could result in personal injury or unit damage.

![]() CAUTION: Operation of unit on improper line volt- age constitutes abuse and could affect warranty. Refer to Table 5 for permissible operating limits. Do not install unit in system where voltage may fluctuate above or below permissible limits.

CAUTION: Operation of unit on improper line volt- age constitutes abuse and could affect warranty. Refer to Table 5 for permissible operating limits. Do not install unit in system where voltage may fluctuate above or below permissible limits.

NOTE: Use copper wire only between disconnect switch(es) and unit.

NOTE: Install branch circuit disconnect of adequate size to handle unit starting current per NEC. Locate disconnect within sight of, and readily accessible from, unit, per Section

1. Route ground and power wires.

![]() WARNING: According to NEC and most local codes, the unit must have an uninterrupted, unbroken ground to minimize personal injury if an electric fault should occur. The ground may consist of electrical wire or metal conduit when installed in accordance with existing electrical codes. Failure to follow this warning could result in an electric shock, fire, or death.

WARNING: According to NEC and most local codes, the unit must have an uninterrupted, unbroken ground to minimize personal injury if an electric fault should occur. The ground may consist of electrical wire or metal conduit when installed in accordance with existing electrical codes. Failure to follow this warning could result in an electric shock, fire, or death.

2.Route line power leads (see Fig. 16) from indoor disconnect to the fan coil unit. Place wire through hole on the control box (Fig. 17). Connect wire to high voltage terminal board (TB1) and ground screw. When routing the wire in the unit, use care to keep the wire away from refrigerant and condensate piping and any sharp edges. The

Table 5 — Electrical Data*

SYSTEM | UNIT | FAN |

| HEATER |

| POWER |

| MIN WIRE SIZE | ||

TYPE | SIZE | Motor 1 FLA |

| Motor 2 FLA | kW | FLA | MCA | MOCP | FLA | (AWG) |

| 024† | 0.5 |

| — | — | — | 0.53 | 15 | 0.50 | 14 |

COOLING | 036 | 1.3 |

| — | — | — | 1.60 | 15 | 1.30 | 14 |

ONLY | 048 | 1.1 |

| 0.5 | — | — | 2.00 | 15 | 1.60 | 14 |

| 060 | 1.3 |

| 1.3 | — | — | 3.30 | 15 | 2.60 | 14 |

| 024† | 0.5 |

| — | 2.00 | 8.66 | 9.29 | 15 | 9.16 | 14 |

HEAT PUMP | 036 | 1.3 |

| — | 3.00 | 13.00 | 17.70 | 20 | 14.30 | 14 |

048 | 1.0 |

| 0.5 | 4.00 | 17.40 | 23.80 | 25 | 19.00 | 12 | |

|

| |||||||||

| 060 | 1.3 |

| 1.3 | 5.00 | 21.70 | 28.70 | 30 | 24.30 | 10 |

| LEGEND |

AWG | — American Wire Gage |

FLA | — Full Load Amps |

MCA | — Minimum Circuit Amps per NEC Section |

MOCP | — Maximum Overcurrent Protection |

NEC | — National Electrical Code |

*All units are

†Electrical data is the same for both the 24,000 Btuh 024 unit and the 024 unit that has been