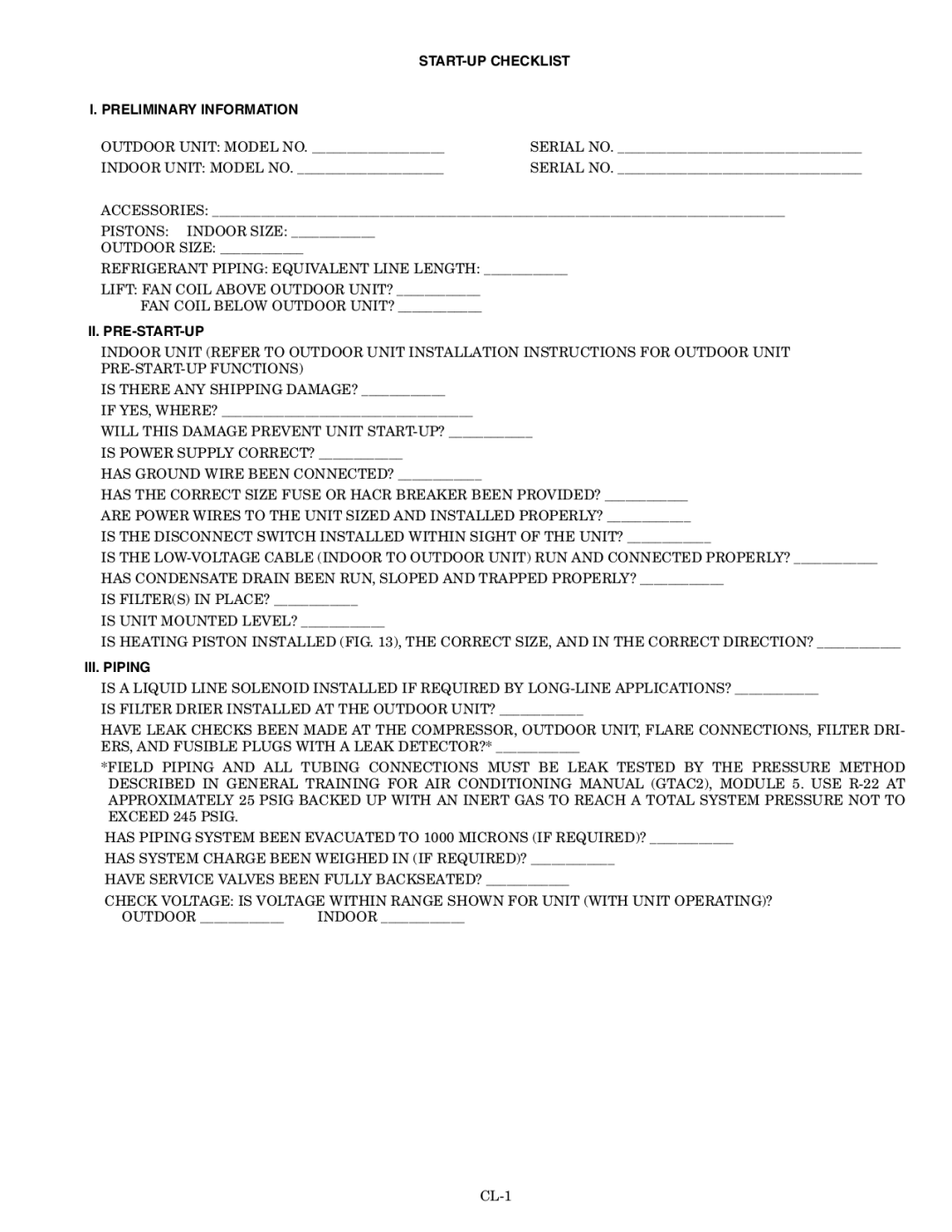

START-UP CHECKLIST

I. PRELIMINARY INFORMATION |

|

OUTDOOR UNIT: MODEL NO. ___________________ | SERIAL NO. ___________________________________ |

INDOOR UNIT: MODEL NO. _____________________ | SERIAL NO. ___________________________________ |

ACCESSORIES: __________________________________________________________________________________

PISTONS: INDOOR SIZE: ____________

OUTDOOR SIZE: ____________

REFRIGERANT PIPING: EQUIVALENT LINE LENGTH: ____________

LIFT: FAN COIL ABOVE OUTDOOR UNIT? ____________

FAN COIL BELOW OUTDOOR UNIT? ____________

II. PRE-START-UP

INDOOR UNIT (REFER TO OUTDOOR UNIT INSTALLATION INSTRUCTIONS FOR OUTDOOR UNIT

IS THERE ANY SHIPPING DAMAGE? ____________

IF YES, WHERE? ____________________________________

WILL THIS DAMAGE PREVENT UNIT

IS POWER SUPPLY CORRECT? ____________

HAS GROUND WIRE BEEN CONNECTED? ____________

HAS THE CORRECT SIZE FUSE OR HACR BREAKER BEEN PROVIDED? ____________

ARE POWER WIRES TO THE UNIT SIZED AND INSTALLED PROPERLY? ____________

IS THE DISCONNECT SWITCH INSTALLED WITHIN SIGHT OF THE UNIT? ____________

IS THE

HAS CONDENSATE DRAIN BEEN RUN, SLOPED AND TRAPPED PROPERLY? ____________

IS FILTER(S) IN PLACE? ____________

IS UNIT MOUNTED LEVEL? ____________

IS HEATING PISTON INSTALLED (FIG. 13), THE CORRECT SIZE, AND IN THE CORRECT DIRECTION? ____________

III. PIPING

IS A LIQUID LINE SOLENOID INSTALLED IF REQUIRED BY

IS FILTER DRIER INSTALLED AT THE OUTDOOR UNIT? ____________

HAVE LEAK CHECKS BEEN MADE AT THE COMPRESSOR, OUTDOOR UNIT, FLARE CONNECTIONS, FILTER DRI- ERS, AND FUSIBLE PLUGS WITH A LEAK DETECTOR?* ____________

*FIELD PIPING AND ALL TUBING CONNECTIONS MUST BE LEAK TESTED BY THE PRESSURE METHOD DESCRIBED IN GENERAL TRAINING FOR AIR CONDITIONING MANUAL (GTAC2), MODULE 5. USE

HAS PIPING SYSTEM BEEN EVACUATED TO 1000 MICRONS (IF REQUIRED)? ____________

HAS SYSTEM CHARGE BEEN WEIGHED IN (IF REQUIRED)? ____________

HAVE SERVICE VALVES BEEN FULLY BACKSEATED? ____________

CHECK VOLTAGE: IS VOLTAGE WITHIN RANGE SHOWN FOR UNIT (WITH UNIT OPERATING)?

OUTDOOR ____________ | INDOOR ____________ |