Section 4 — Maintenance

Bryant

4.1MAINTENANCE PERFORMED BY AUTHORIZED SERVICE FACILITIES

A. EVERY THREE MONTHS

1.Check battery condition.

2.Inspect and test fuel system.

3.Check transfer switch.

4.Inspect exhaust system.

5.Check engine ignition system.

6.Check fan belts.

B. ONCE EVERY SIX MONTHS

1.Test Engine Safety Devices (low oil pressure, low coolant level, high coolant temperature).

C. ONCE ANNUALLY

1.Test engine governor; adjust or repair, if needed.

2.Clean, inspect generator.

3.Flush cooling system.

D. FIRST 100 OPERATING HOURS

1.Change engine oil and oil filter. After initial change, service engine oil and filter at 150 oper- ating hours or six months, whichever comes first.

2.Retorque cylinder head (see torque specs).

3.Retorque intake and exhaust manifold (see torque specs).

E. EVERY 500 OPERATING HOURS

1.Service air cleaner.

2.Check starter.

3.Check engine DC alternator.

4.3INTAKE MANIFOLD PROCEDURE

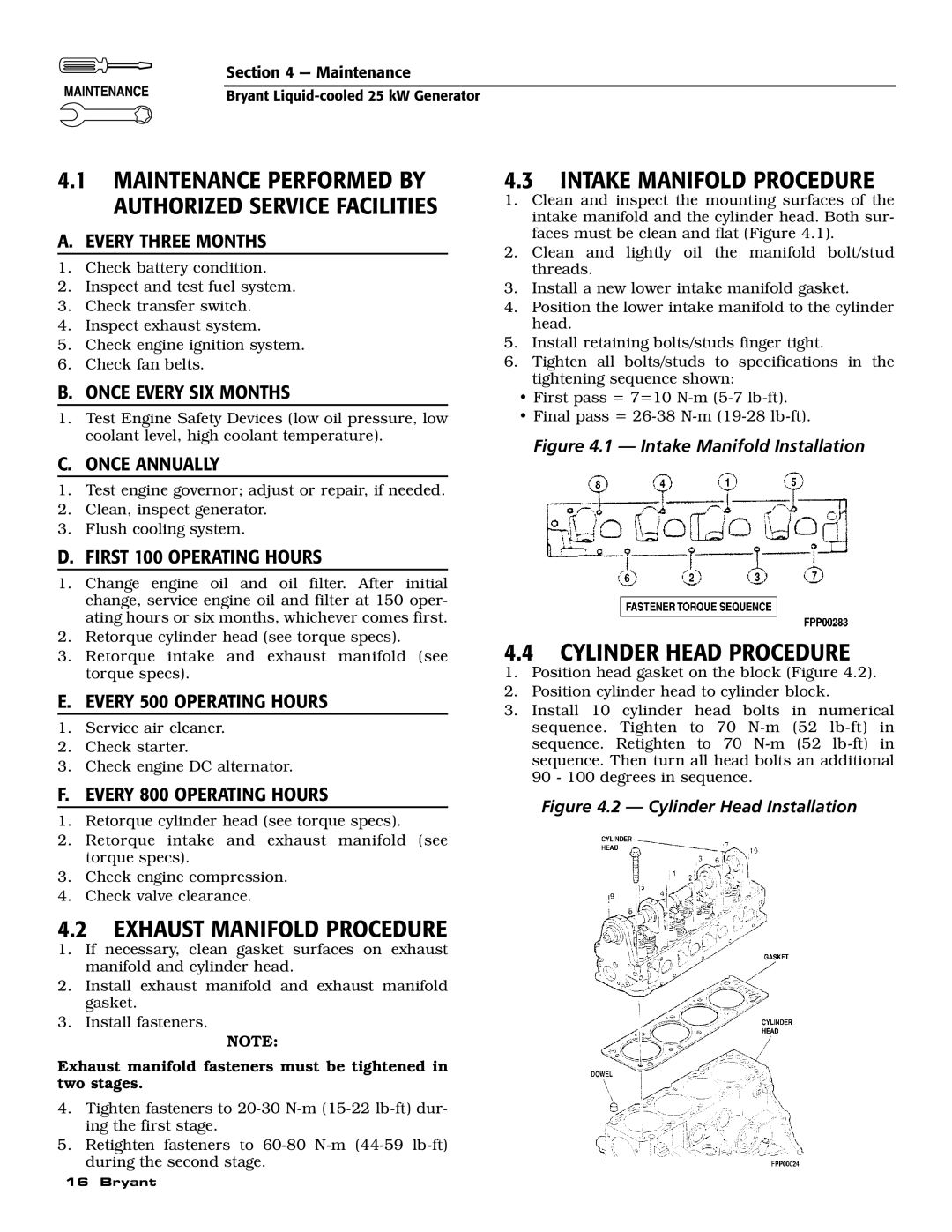

1.Clean and inspect the mounting surfaces of the intake manifold and the cylinder head. Both sur- faces must be clean and flat (Figure 4.1).

2.Clean and lightly oil the manifold bolt/stud threads.

3.Install a new lower intake manifold gasket.

4.Position the lower intake manifold to the cylinder head.

5.Install retaining bolts/studs finger tight.

6.Tighten all bolts/studs to specifications in the tightening sequence shown:

•First pass = 7=10

•Final pass =

Figure 4.1 — Intake Manifold Installation

4.4CYLINDER HEAD PROCEDURE

1.Position head gasket on the block (Figure 4.2).

2.Position cylinder head to cylinder block.

3.Install 10 cylinder head bolts in numerical sequence. Tighten to 70

F. EVERY 800 OPERATING HOURS

Figure 4.2 — Cylinder Head Installation

1.Retorque cylinder head (see torque specs).

2.Retorque intake and exhaust manifold (see torque specs).

3.Check engine compression.

4.Check valve clearance.

4.2EXHAUST MANIFOLD PROCEDURE

1.If necessary, clean gasket surfaces on exhaust manifold and cylinder head.

2.Install exhaust manifold and exhaust manifold gasket.

3.Install fasteners.

NOTE:

Exhaust manifold fasteners must be tightened in two stages.

4.Tighten fasteners to

5.Retighten fasteners to

16 Bryant