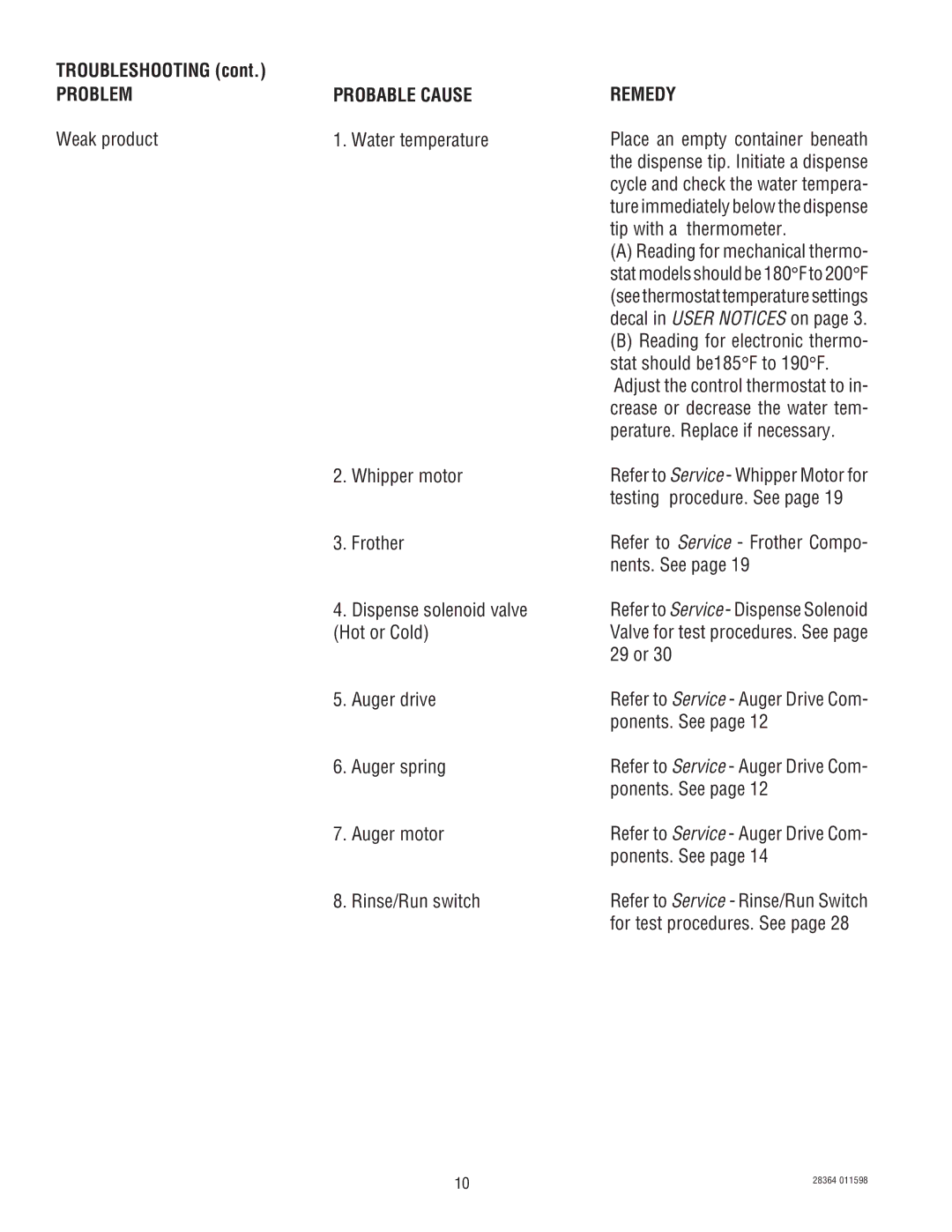

TROUBLESHOOTING (cont.)

PROBLEM

Weak product

PROBABLE CAUSE | REMEDY | |

1. | Water temperature | Place an empty container beneath |

|

| the dispense tip. Initiate a dispense |

|

| cycle and check the water tempera- |

|

| ture immediately below the dispense |

|

| tip with a thermometer. |

|

| (A) Reading for mechanical thermo- |

|

| stat models should be 180°F to 200°F |

|

| (see thermostat temperature settings |

|

| decal in USER NOTICES on page 3. |

|

| (B) Reading for electronic thermo- |

|

| stat should be185°F to 190°F. |

|

| Adjust the control thermostat to in- |

|

| crease or decrease the water tem- |

|

| perature. Replace if necessary. |

2. | Whipper motor | Refer to Service - Whipper Motor for |

|

| testing procedure. See page 19 |

3. | Frother | Refer to Service - Frother Compo- |

|

| nents. See page 19 |

4. | Dispense solenoid valve | Refer to Service - Dispense Solenoid |

(Hot or Cold) | Valve for test procedures. See page | |

|

| 29 or 30 |

5. | Auger drive | Refer to Service - Auger Drive Com- |

|

| ponents. See page 12 |

6. | Auger spring | Refer to Service - Auger Drive Com- |

|

| ponents. See page 12 |

7. | Auger motor | Refer to Service - Auger Drive Com- |

|

| ponents. See page 14 |

8. | Rinse/Run switch | Refer to Service - Rinse/Run Switch |

|

| for test procedures. See page 28 |

10 | 28364 011598 |

|