APPENDIX A – Combustion Air

PROVIDE ENOUGH AIR to ventilate the boiler room, dilute the flue gases, and

sustain combustion. Ignition failure, overheating, fire, carbon monoxide, and spillage of flue gases may result from poor air supply.

If the boiler is a Direct Vent boiler and exchanges all combustion air and combustion products directly with the outdoors, there are no special requirements for providing combustion, ventilation, and dilution air.

If the boiler is chimney vented, power vented or induced draft and draws combustion air from within the building, follow the steps below to determine how to provide air to the boiler.

Is the boiler located in a confined space?:

1.Calculate the floorspace (in square feet) of the boiler room and all rooms connected to the boiler room by passageways not furnished with doors.

___________ floorspace (sq. ft.)

2.Add up the input rates of all the combustion appliances installed in the same floorspace.

combined appliance

___________ input (BTU/hr)

3.In the table below, find the Minimum Allowable Floorspace based on the

Combined Input Rate from Step 2 and the ceiling height. If the Combined Input Rate is between two rates, use the next highest rate.

minimum allowable

___________ floorspace (sq. ft.)

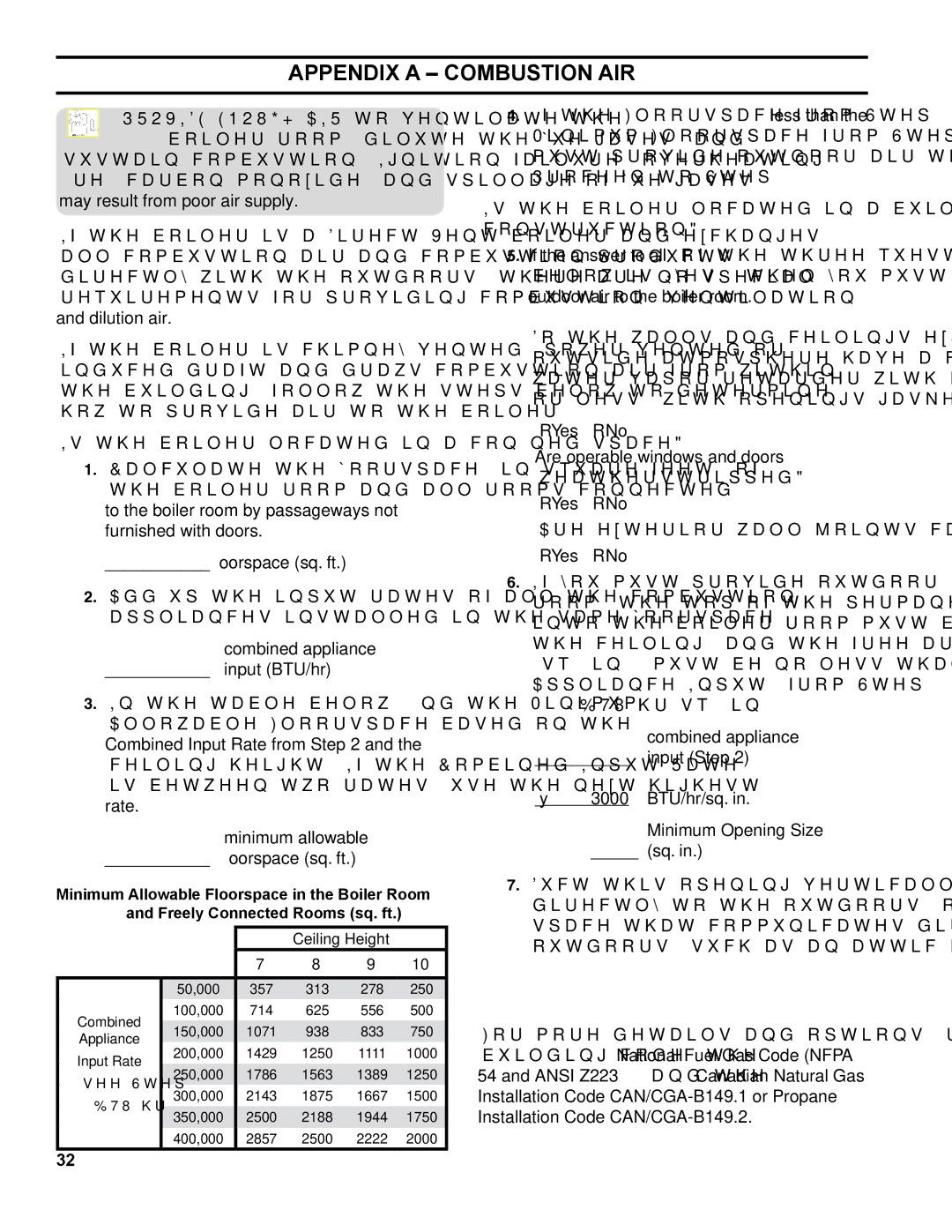

Minimum Allowable Floorspace in the Boiler Room and Freely Connected Rooms (sq. ft.)

|

|

| Ceiling Height |

| ||

|

| 7’ | 8’ | 9’ | 10’ | |

|

|

|

|

|

| |

| 50,000 | 357 | 313 | 278 | 250 | |

Combined | 100,000 | 714 | 625 | 556 | 500 | |

150,000 | 1071 | 938 | 833 | 750 | ||

Appliance | ||||||

200,000 | 1429 | 1250 | 1111 | 1000 | ||

Input Rate | ||||||

250,000 | 1786 | 1563 | 1389 | 1250 | ||

(see Step 2) | ||||||

300,000 | 2143 | 1875 | 1667 | 1500 | ||

(BTU/hr) | ||||||

350,000 | 2500 | 2188 | 1944 | 1750 | ||

| ||||||

| 400,000 | 2857 | 2500 | 2222 | 2000 | |

32

4.If the Floorspace from Step 1 is less than the Minimum Floorspace from Step 3, then you must provide outdoor air to the boiler room. Proceed to Step 6.

Is the boiler located in a building of unusually tight construction?

5.If the answer to all of the three questions below is “yes”, then you must provide outdoor air to the boiler room.

Do the walls and ceilings exposed to the outside atmosphere have a continuous water vapor retarder with a rating of 1 perm or less, with openings gasket or sealed?

Yes No

Are operable windows and doors weatherstripped?

Yes No

Are exterior wall joints caulked or sealed?

Yes No

6.If you must provide outdoor air to the boiler room, the top of the permanent opening into the boiler room must be within 12” of the ceiling, and the free area of the opening (sq. in.) must be no less than the Combined Appliance Input (from Step 2) divided by 3000 BTU/hr/sq. in.

combined appliance

__________ input (Step 2)

⎟3000 BTU/hr/sq. in.

Minimum Opening Size

_____ (sq. in.)

7.Duct this opening vertically or horizontally directly to the outdoors, or directly to a space that communicates directly with the outdoors, such as an attic or crawlspace.

For more details and options, refer to your local building code, the National Fuel Gas Code (NFPA 54 and ANSI Z223), and the Canadian Natural Gas Installation Code