APPENDIX D – System Piping (continued)

(2)Comply with the boiler’s specific water quality requirements. See the Specifications Section of this manual.

(3)Comply with the boiler’s specific requirements for minimum water flow through the boiler, installing a system bypass or

3.Overpressure

(1)Install a properly sized expansion tank.

(2)Do not exceed the boiler’s specific requirements for maximum allowable working pressure.

(3)Do not plug or block the relief valve.

4.Freezing

(1)Run all portions of the system piping inside a heated space unless the system is properly protected with an inhibited antifreeze solution.

5.Overheating

(1)Comply with the boiler’s specific requirement for minimum water flow through the boiler. See the

Specifications Section of this manual.

(2)Install a

or radiator. Also add a

6.Thermal shock

(1)Do not

(2)Install a boiler bypass, system bypass, or

7.Condensation

(1)Do not

(2)Adhere to the boiler’s specific minimum return water and supply water temperature requirements. Install a boiler bypass, system bypass, or

(3)Do not allow chilled water to enter the boiler during the heating cycle, or heated water to enter chilled water coils during the cooling cycle.

8.Dry Fire

Install a

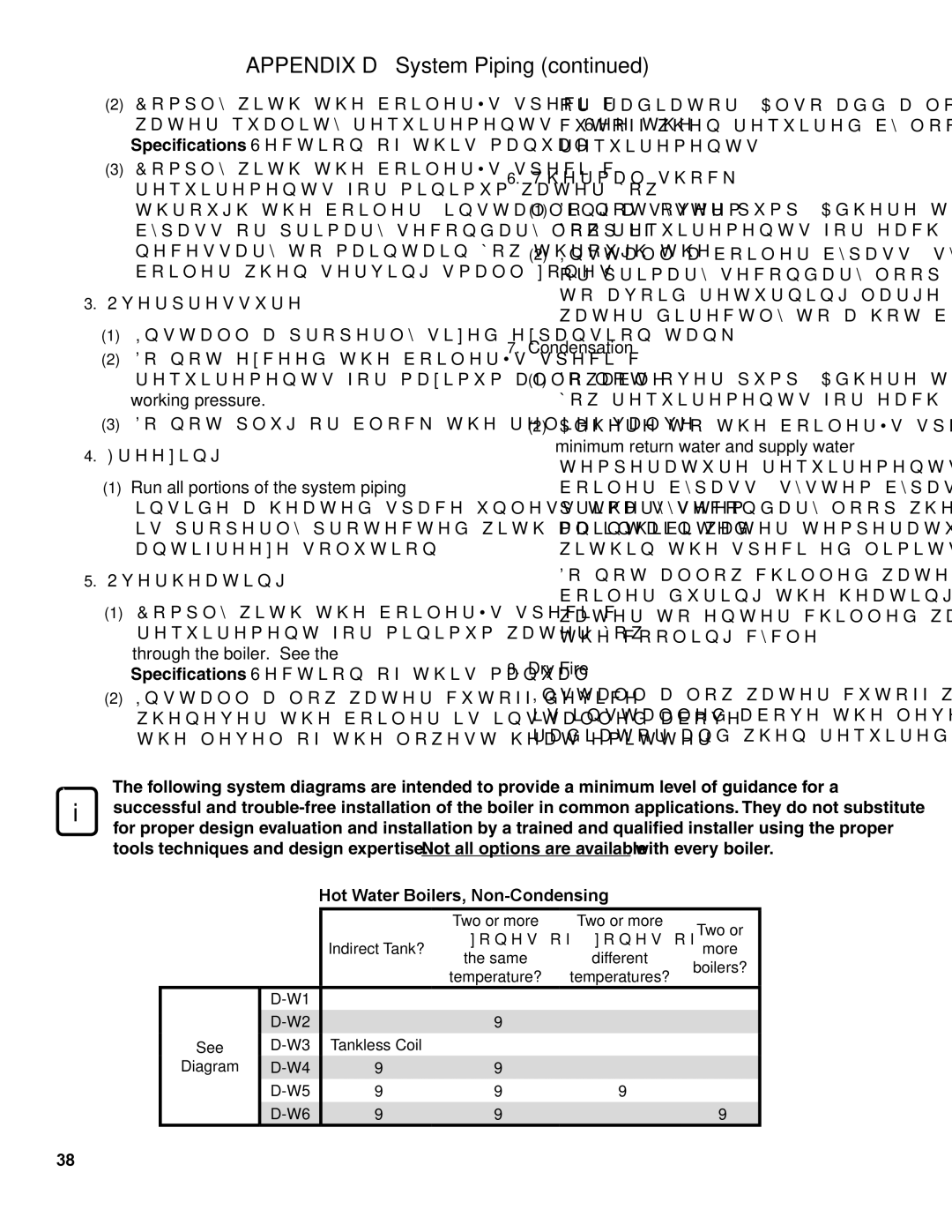

The following system diagrams are intended to provide a minimum level of guidance for a

i successful and

Hot Water Boilers, Non-Condensing

|

|

| Two or more | Two or more | Two or |

|

|

| zones of | zones of | |

|

| Indirect Tank? | more | ||

|

| the same | different | ||

|

|

| boilers? | ||

|

|

| temperature? | temperatures? | |

|

|

|

| ||

|

|

|

|

| |

|

| |

|

| |

See | Tankless Coil |

|

|

| |

Diagram | | |

|

| |

| | | |

| |

| | |

| |

38