APPENDIX F – Adjusting Gas Input Rate (continued)

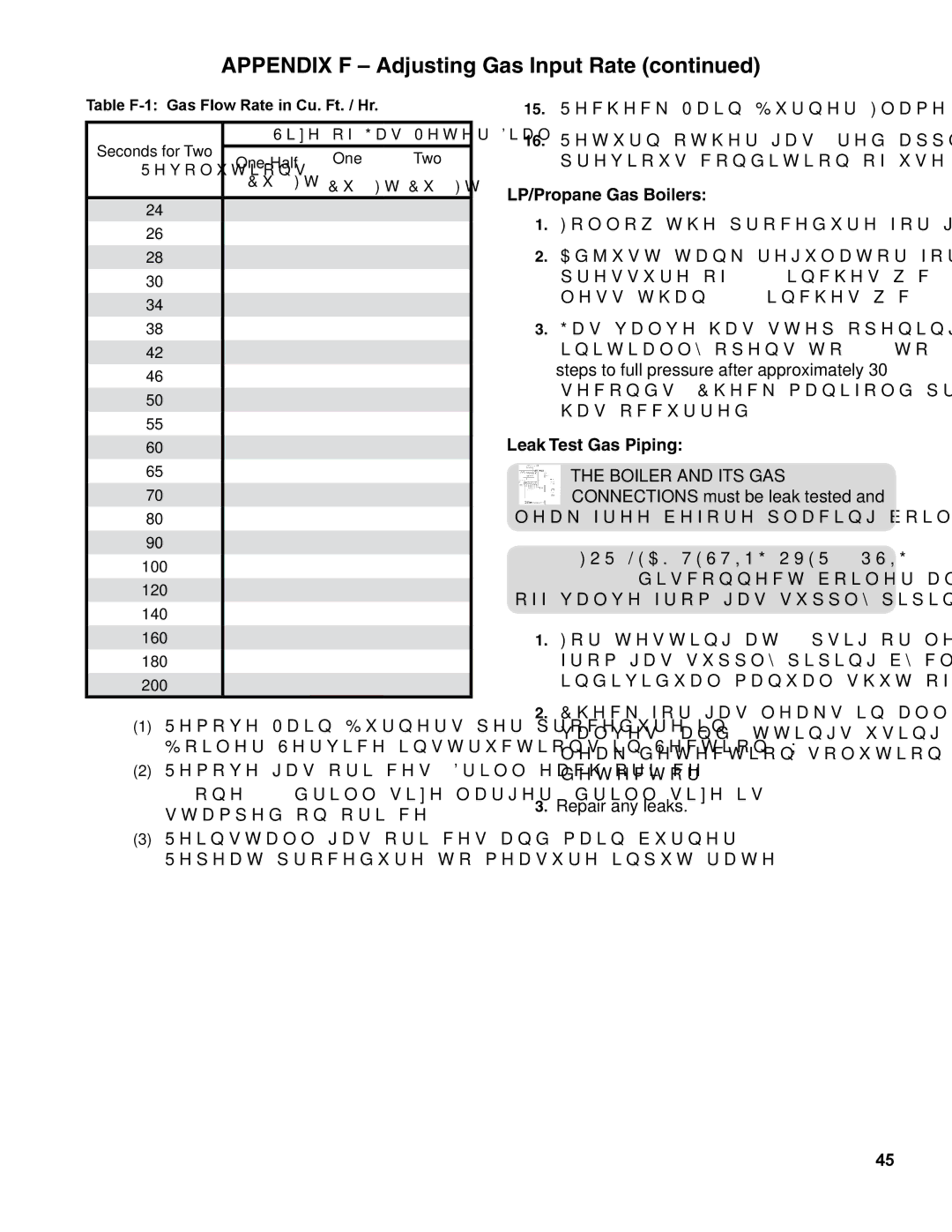

Table F-1: Gas Flow Rate in Cu. Ft. / Hr.

Seconds for Two | Size of Gas Meter Dial | |||

One | Two | |||

(2) Revolutions | ||||

Cu. Ft. | Cu. Ft. | Cu. Ft. | ||

| ||||

24 | 150.0 | 300.0 | 450.0 | |

26 | 138.4 | 276.9 | 415.3 | |

28 | 128.5 | 257.1 | 385.7 | |

30 | 120.0 | 240.0 | 360.0 | |

34 | 105.8 | 211.7 | 317.6 | |

38 | 94.7 | 189.4 | 284.2 | |

42 | 85.7 | 171.4 | 257.1 | |

46 | 78.2 | 156.5 | 234.7 | |

50 | 72.0 | 144.0 | 216.0 | |

55 | 65.4 | 130.9 | 196.3 | |

60 | 60.0 | 120.0 | 180.0 | |

65 | 55.3 | 110.7 | 166.1 | |

70 | 51.4 | 102.8 | 154.2 | |

80 | 45.0 | 90.0 | 135.0 | |

90 | 40.0 | 80.0 | 120.0 | |

100 | 36.0 | 72.0 | 108.0 | |

120 | 30.0 | 60.0 | 90.0 | |

140 | 25.7 | 51.4 | 77.1 | |

160 | 22.5 | 47.0 | 67.5 | |

180 | 20.0 | 40.0 | 60.0 | |

200 | 18.0 | 36.0 | 54.0 | |

(1)Remove Main Burners per procedure in Boiler Service instructions in Section (X).

(2)Remove gas orifices. Drill each orifice

one (1) drill size larger (drill size is stamped on orifice).

(3)Reinstall gas orifices and main burner. Repeat procedure to measure input rate.

15.Recheck Main Burner Flame.

16.Return other

LP/Propane Gas Boilers:

1.Follow the procedure for gas boilers, except:

2.Adjust tank regulator for gas valve inlet pressure of 13.5 inches w.c. or less, but not less than 11.5 inches w.c.

3.Gas valve has

Leak Test Gas Piping:

The boiler and its gas connections must be leak tested and

leak free before placing boiler in operation.

For leak testing over ½ psig, disconnect boiler and its individual shut-

off valve from gas supply piping.

1.For testing at ½ psig or less, isolate boiler from gas supply piping by closing boiler’s individual manual

2.Check for gas leaks in all piping joints, valves, and fittings using a

3.Repair any leaks.

45