APPENDIX F – Adjusting Gas Input Rate

Natural Gas Boilers:

1.Turn off gas supply to all appliances other than

2.Note the rated manifold gas pressure listed on the boiler’s rating label.

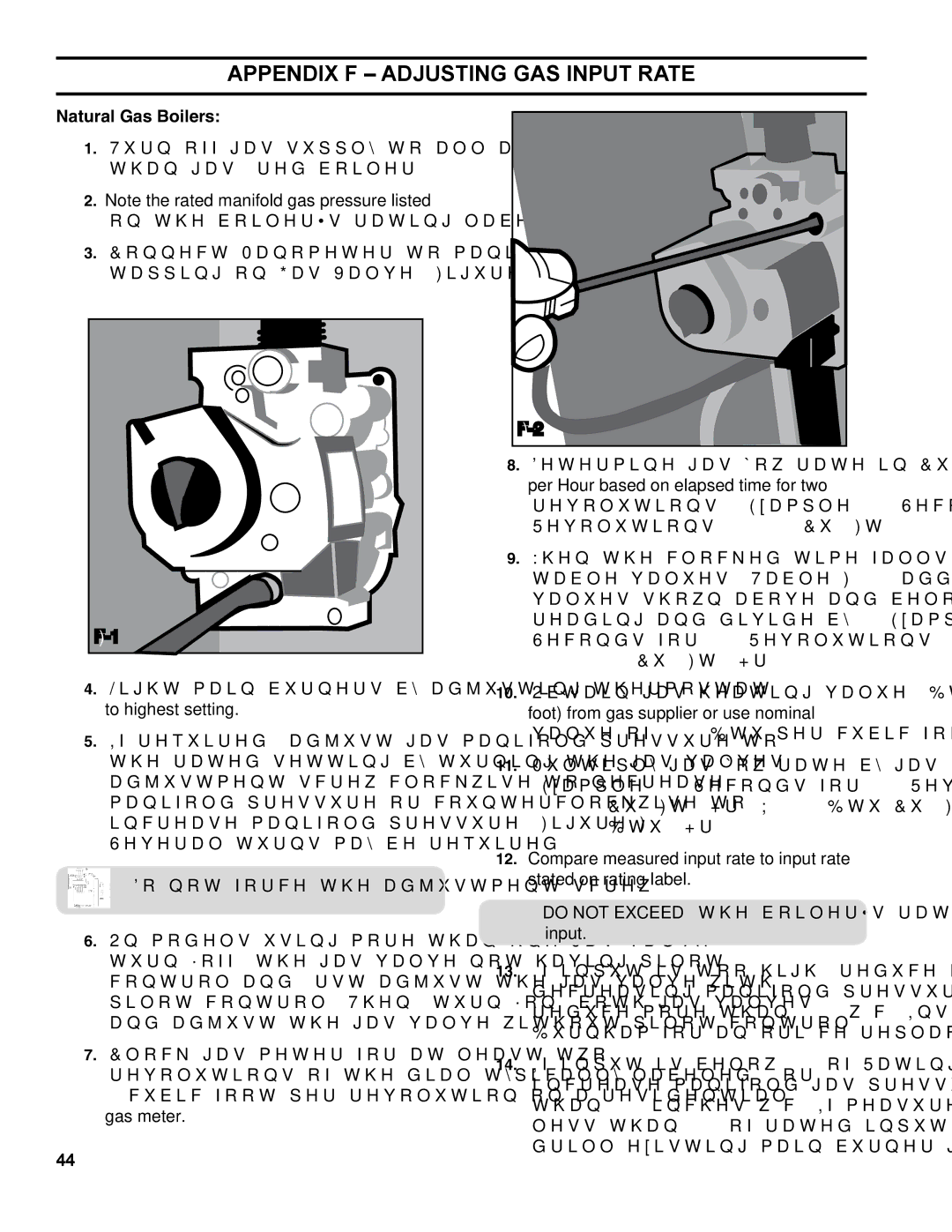

3.Connect Manometer to manifold pressure tapping on Gas Valve (Figure

4.Light main burners by adjusting thermostat to highest setting.

5.If required, adjust gas manifold pressure to the rated setting by turning the gas valves adjustment screw clockwise to decrease manifold pressure or counterclockwise to increase manifold pressure (Figure

Do not force the adjustment screw.

6.On models using more than one gas valve, turn “off” the gas valve not having pilot control and first adjust the gas valve with pilot control. Then, turn “on” both gas valves and adjust the gas valve without pilot control.

7.Clock gas meter for at least two (2) revolutions of the dial typically labeled ½ or 1 cubic foot per revolution on a residential gas meter.

44

8.Determine gas flow rate in Cubic Feet per Hour based on elapsed time for two revolutions. (Example: 70 Seconds for (2) Revolutions = 102.8 Cu. Ft.

9.When the clocked time falls between two table values (Table

10.Obtain

11.Multiply gas flow rate by gas heating value. (Example: 70 Seconds for (2) Revolutions = 120.8 Cu. Ft./Hr. X 1027 Btu/Cu. Ft. = 124,061 Btu/ Hr.

12.Compare measured input rate to input rate stated on rating label.

Do not exceed the boiler’s rated gas input.

13.If input is too high, reduce input rate by decreasing manifold pressure. Do not reduce more than 0.3” w.c. Instead, contact Burnham for an orifice replacement kit.

14.If input is below 98% of Rating Label input, increase manifold gas pressure no more than 0.3 inches w.c. If measured rate is still less than 98% of rated input, replace or re- drill existing main burner gas orifices: