B.See Figure 22 for continuous ignition system (standing pilot).

4. CHECK GAS INPUT RATE TO BOILER

NOTICE![]()

USA boilers built for installation at altitudes greater than 2,000 feet above sea level have been specially orificed to reduce gas input rate 4 percent per 1,000 feet above sea level per the National Fuel Gas Code, NFPA 54/ANSI Z223.1, Section 8.1.2 and Appendix F. Canadian boilers' orifice sizing is indicated on the rating label. High altitude boiler models are identifiable by the fourth digit after the dash in the model number. 2:

A.Input Rate and Maximum Inlet Pressure shown on Rating Label must not be exceeded. Inlet pressure must not be lower than minimum inlet pressure shown on Rating Label.

B.All Rate checks and all adjustments are to be made while boiler is firing - all other appliances connected to the same meter as the boiler must be off.

C.With boiler off, water Manometer or water column gauge should be connected to a

D.LP Gas Input:

Adjust Regulator on Gas Valve so that manifold pressure is 10 inches water column. Turning Regulator Adjusting Screw Clockwise increases pressure. Counterclockwise rotation decreases pressure.

more accurate check on input is necessary see

(2) below.

For minor input changes readjust Regulator Gas Valve to increase or decrease manifold pressure to obtain corresponding increase or decrease in gas input. If it is necessary to increase manifold pressure more than 0.3" of water to obtain rated input, remove orifices and drill one size larger.

Reinstall and recheck input rate.

2.Additional Check on Input - Since input is a function of heating value, specific gravity, and volume of gas flow contact your utility for the first two items in order to utilize the formula below. The gas meter should then be clocked for three (3) minutes with stop watch and substituting the appropriate values in the formula below, determine what the gas flow should be in this 3 minute period to give the input shown on the Rating Label:

Gas Input | = |

| Btuh Input |

|

(cu. ft.) | Heating |

| Multiplier | |

|

| |||

per 3 min. |

| Value | X | from |

|

| of Gas |

| Table 3 |

|

| (Btu / cu. ft. |

|

|

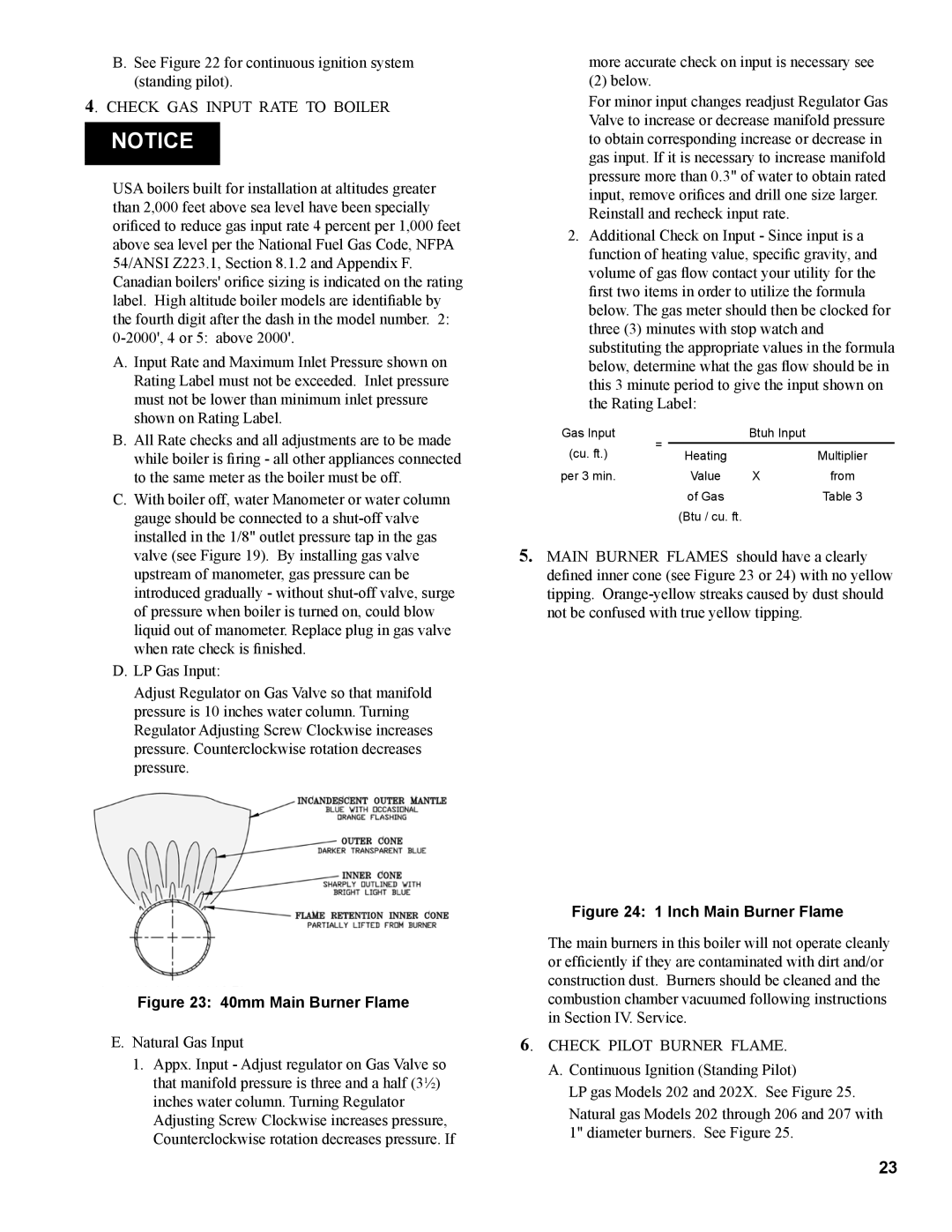

5.MAIN BURNER FLAMES should have a clearly defined inner cone (see Figure 23 or 24) with no yellow tipping.

Figure 23: 40mm Main Burner Flame

E.Natural Gas Input

1.Appx. Input - Adjust regulator on Gas Valve so that manifold pressure is three and a half (3½) inches water column. Turning Regulator Adjusting Screw Clockwise increases pressure, Counterclockwise rotation decreases pressure. If

Figure 24: 1 Inch Main Burner Flame

The main burners in this boiler will not operate cleanly or efficiently if they are contaminated with dirt and/or construction dust. Burners should be cleaned and the combustion chamber vacuumed following instructions in Section IV. Service.

6. CHECK PILOT BURNER FLAME.

A.Continuous Ignition (Standing Pilot)

LP gas Models 202 and 202X. See Figure 25.

Natural gas Models 202 through 206 and 207 with 1" diameter burners. See Figure 25.

23