|

| Operating Instructions and Parts Manual | |

Setup (continued) | NOTICE: Some latex finishes are very | b. Estimate the time interval between | |

6. Install the appropriate needle/nozzle | thick and require the greatest amount | each of the first three drips of | |

of thinning and mixing. A latex paint | material. The time between the | ||

assembly selected for the material to | conditioner can be added to the | first three drips of material will vary | |

be sprayed (Fig. 2, 3 & 4 ). | paint to improve spray performance | depending on the thickness or the | |

7. Reassemble the needle assembly, | (available at most home centers). | ||

“viscosity” of the material. | |||

spring, material control knob, | 1. Strain paint before spraying. | ||

c. The material is adequately thinned if | |||

nozzle, air cap, and retainer ring. | Unstrained paint may affect | ||

the first three drips from the viscosity | |||

| |||

ADJUSTING PACKING | material flow and spray pattern. | ||

stick are about one second apart. | |||

Occasionally the packing nut, located | When spraying thin materials such | ||

| |||

forward of the trigger assembly, will | as lacquer or stains, consult with | d. As a general rule, if the time | |

require adjustment. The packing nut | the material supplier for the proper | between drips is more than one | |

will also require adjustment when the | strainer mesh number. | second, the material is too thick. | |

needle/nozzle assembly is changed | 2. Pour material into the paint cup. | Add thinning agent, stir thoroughly | |

(Figure 6). | Fill the material cup only 1/2 to 3/4 | and repeat the above procedure | |

1. Turn the material flow control knob | |||

full if thinning of the material is | until the proper viscosity is attained. | ||

clockwise at least 3/4 of the way in. | required. (See Figure 7). Refer to |

| |

2. Tighten the packing nut with | the material chart below for proper | Viscosity Stick (Located | |

the wrench by turning the nut | thinning instructions. | ||

Inside The Storage | |||

clockwise until the needle will |

| ||

| Compartment) | ||

not return to the closed position |

| ||

|

| ||

when the trigger is released. Do |

|

| |

not overtighten the packing nut. |

|

| |

To properly adjust the packing, the |

|

| |

nut should be tightened no further |

|

| |

than is required to stop the needle |

|

| |

from returning. (See Figure 6). |

|

|

Material Flow |

|

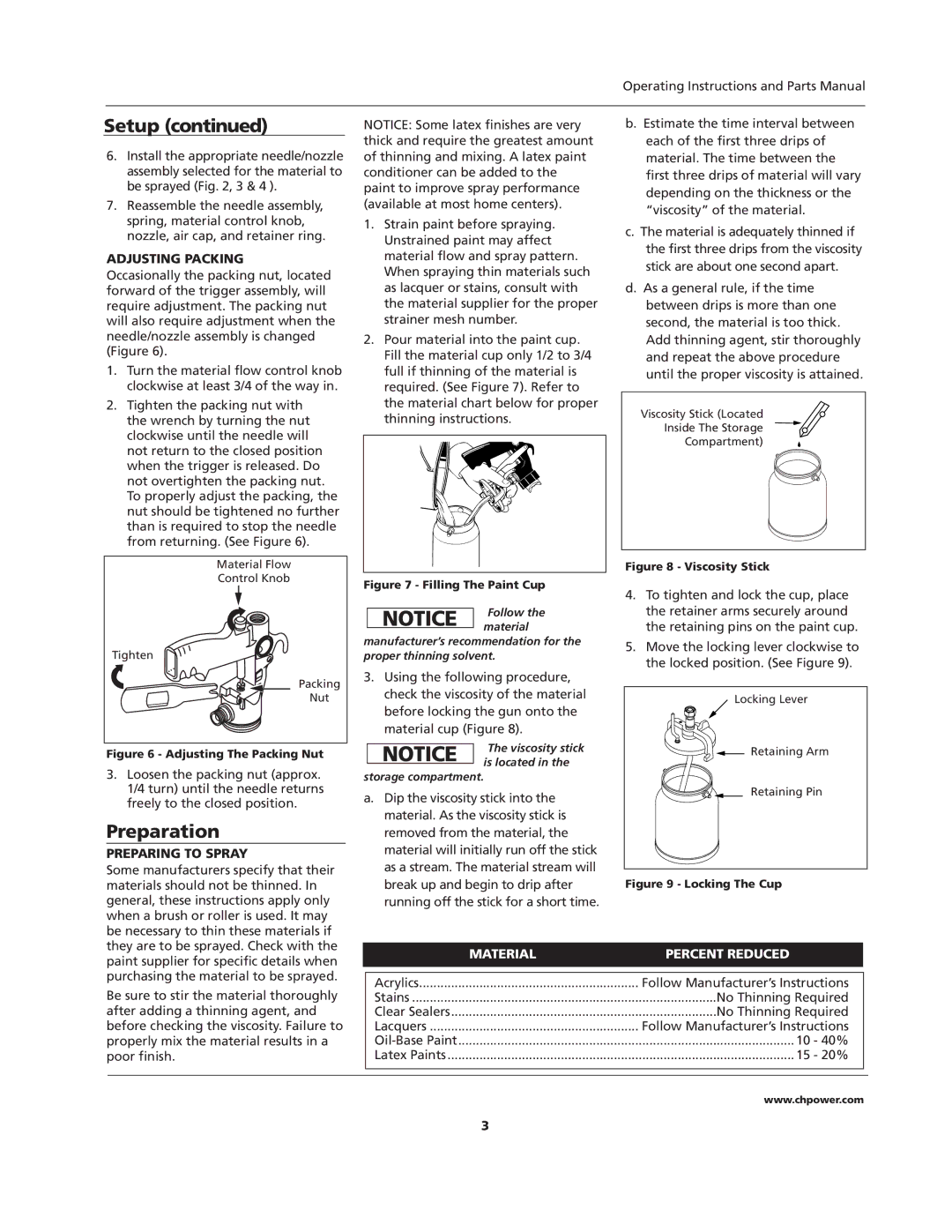

| Figure 8 - Viscosity Stick | |

Control Knob | Figure 7 - Filling The Paint Cup |

| ||

| 4. To tighten and lock the cup, place | |||

|

|

| ||

| NOTICE | Follow the | the retainer arms securely around | |

| material | the retaining pins on the paint cup. | ||

| manufacturer’s recommendation for the | 5. Move the locking lever clockwise to | ||

Tighten | proper thinning solvent. | |||

the locked position. (See Figure 9). | ||||

| 3. Using the following procedure, | |||

Packing |

| |||

check the viscosity of the material |

| |||

Nut | Locking Lever | |||

before locking the gun onto the | ||||

|

| |||

| material cup (Figure 8). |

| ||

Figure 6 - Adjusting The Packing Nut | NOTICE | The viscosity stick | Retaining Arm | |

is located in the | ||||

|

| |||

3. Loosen the packing nut (approx. | storage compartment. |

| ||

1/4 turn) until the needle returns | a. Dip the viscosity stick into the | Retaining Pin | ||

freely to the closed position. |

| |||

material. As the viscosity stick is |

| |||

Preparation |

| |||

removed from the material, the |

| |||

PREPARING TO SPRAY | material will initially run off the stick |

| ||

Some manufacturers specify that their | as a stream. The material stream will | Figure 9 - Locking The Cup | ||

materials should not be thinned. In | break up and begin to drip after | |||

general, these instructions apply only | running off the stick for a short time. |

| ||

when a brush or roller is used. It may |

|

|

| |

be necessary to thin these materials if |

|

|

| |

they are to be sprayed. Check with the |

| MATERIAL | PERCENT REDUCED | |

paint supplier for specific details when |

| |||

|

|

| ||

purchasing the material to be sprayed. | Acrylics | Follow Manufacturer’s Instructions | ||

Be sure to stir the material thoroughly | ||||

Stains | No Thinning Required | |||

after adding a thinning agent, and | Clear Sealers | No Thinning Required | ||

before checking the viscosity. Failure to | Lacquers | Follow Manufacturer’s Instructions | ||

properly mix the material results in a | 10 - 40% | |||

poor finish. | Latex Paints | 15 - 20% | ||

|

|

| www.chpower.com | |

3