|

|

|

| Operating Instructions and Parts Manual | |||

|

|

|

|

|

|

| |

|

|

|

|

|

|

| |

|

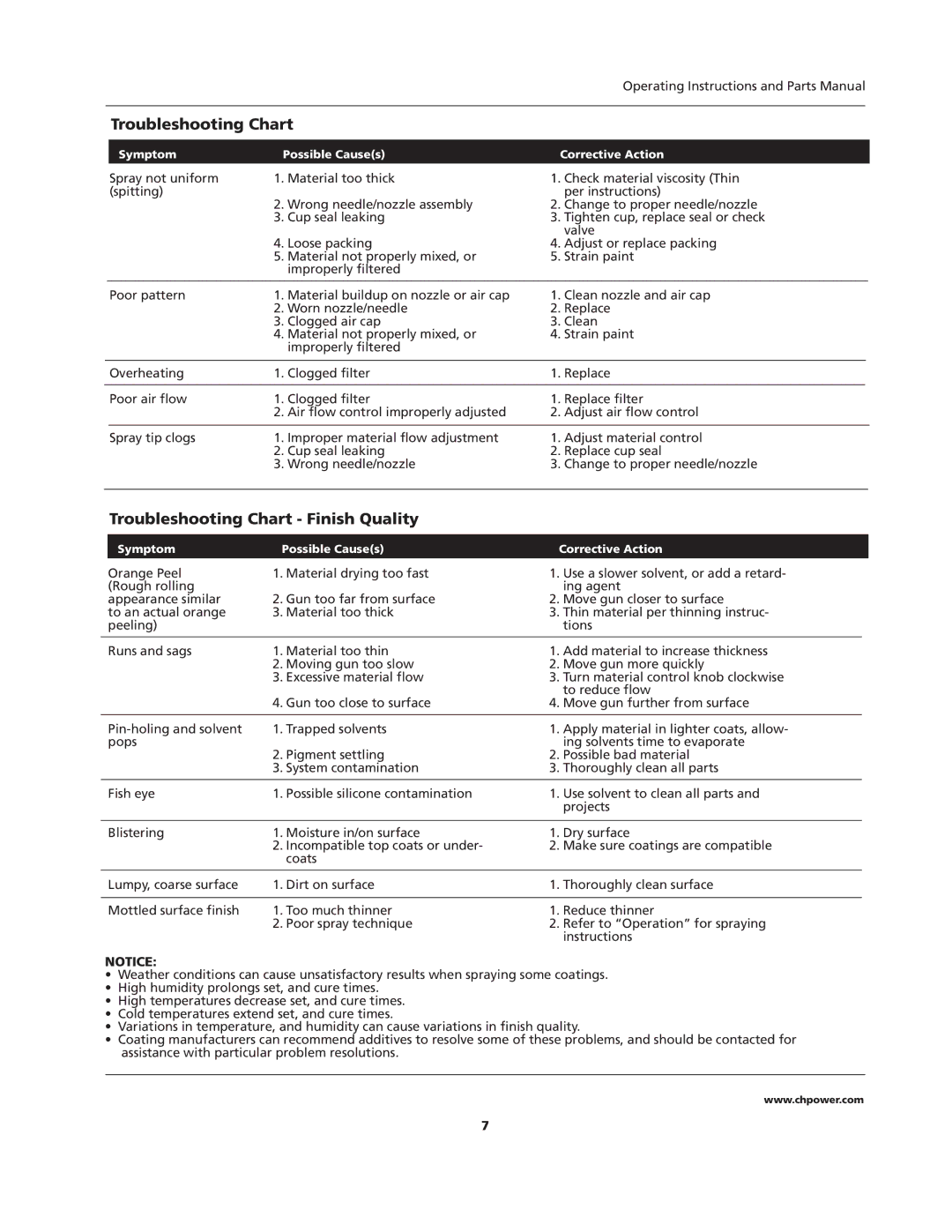

| Troubleshooting Chart |

|

|

|

| |

|

|

|

|

|

|

|

|

|

| Symptom | Possible Cause(s) | Corrective Action | |||

|

| Spray not uniform | 1. Material too thick | 1. Check material viscosity (Thin | |||

|

| (spitting) |

| per instructions) | |||

|

|

| 2. Wrong needle/nozzle assembly | 2. Change to proper needle/nozzle | |||

|

|

| 3. Cup seal leaking | 3. Tighten cup, replace seal or check | |||

|

|

|

| valve | |||

|

|

| 4. Loose packing | 4. Adjust or replace packing | |||

|

|

| 5. Material not properly mixed, or | 5. Strain paint | |||

|

|

| improperly filtered |

|

|

|

|

|

|

|

|

|

|

|

|

|

| Poor pattern | 1. Material buildup on nozzle or air cap | 1. Clean nozzle and air cap | |||

|

|

| 2. Worn nozzle/needle | 2. Replace | |||

|

|

| 3. Clogged air cap | 3. Clean | |||

|

|

| 4. Material not properly mixed, or | 4. Strain paint | |||

|

|

| improperly filtered |

|

|

|

|

|

|

|

|

|

|

|

|

|

| Overheating | 1. Clogged filter | 1. Replace | |||

|

|

|

|

|

|

|

|

|

| Poor air flow | 1. Clogged filter | 1. Replace filter | |||

|

|

| 2. Air flow control improperly adjusted | 2. Adjust air flow control | |||

|

|

|

|

|

|

| |

|

| Spray tip clogs | 1. Improper material flow adjustment | 1. Adjust material control | |||

|

|

| 2. Cup seal leaking | 2. Replace cup seal | |||

|

|

| 3. Wrong needle/nozzle | 3. Change to proper needle/nozzle | |||

|

|

|

|

|

|

| |

|

|

|

|

|

|

| |

|

| Troubleshooting Chart - Finish Quality |

|

|

|

| |

|

|

|

|

|

| ||

|

| Symptom | Possible Cause(s) | Corrective Action | |||

|

| Orange Peel | 1. Material drying too fast | 1. Use a slower solvent, or add a retard- | |||

|

| (Rough rolling |

| ing agent | |||

|

| appearance similar | 2. Gun too far from surface | 2. Move gun closer to surface | |||

|

| to an actual orange | 3. Material too thick | 3. Thin material per thinning instruc- | |||

|

| peeling) |

| tions | |||

|

|

|

|

|

| ||

|

| Runs and sags | 1. Material too thin | 1. Add material to increase thickness | |||

|

|

| 2. Moving gun too slow | 2. Move gun more quickly | |||

|

|

| 3. Excessive material flow | 3. Turn material control knob clockwise | |||

|

|

|

| to reduce flow | |||

|

|

| 4. Gun too close to surface | 4. Move gun further from surface | |||

|

|

|

|

|

| ||

|

| 1. Trapped solvents | 1. Apply material in lighter coats, allow- | ||||

|

| pops |

| ing solvents time to evaporate | |||

|

|

| 2. Pigment settling | 2. Possible bad material | |||

|

|

| 3. System contamination | 3. Thoroughly clean all parts | |||

|

|

|

|

|

| ||

|

| Fish eye | 1. Possible silicone contamination | 1. Use solvent to clean all parts and | |||

|

|

|

| projects | |||

|

|

|

|

|

| ||

|

| Blistering | 1. Moisture in/on surface | 1. Dry surface | |||

|

|

| 2. Incompatible top coats or under- | 2. Make sure coatings are compatible | |||

|

|

| coats |

|

|

|

|

|

|

|

|

|

| ||

|

| Lumpy, coarse surface | 1. Dirt on surface | 1. Thoroughly clean surface | |||

|

|

|

|

|

| ||

|

| Mottled surface finish | 1. Too much thinner | 1. Reduce thinner | |||

|

|

| 2. Poor spray technique | 2. Refer to “Operation” for spraying | |||

|

|

|

| instructions | |||

NOTICE:

•Weather conditions can cause unsatisfactory results when spraying some coatings.

•High humidity prolongs set, and cure times.

•High temperatures decrease set, and cure times.

•Cold temperatures extend set, and cure times.

•Variations in temperature, and humidity can cause variations in finish quality.

•Coating manufacturers can recommend additives to resolve some of these problems, and should be contacted for assistance with particular problem resolutions.

www.chpower.com

7