30HWB CONDENSER Ð When facing the back of the unit, the condenser is the uninsulated heat exchanger located on the right-hand side. The water connections are on the right- hand side of the heat exchanger with the LIQUID-IN con- nection at the bottom, and the LIQUID-OUT connection at the top.

A strainer with a minimum of 20 mesh must be installed ahead of the condenser water inlet to prevent debris from clogging or damaging the heat exchanger.

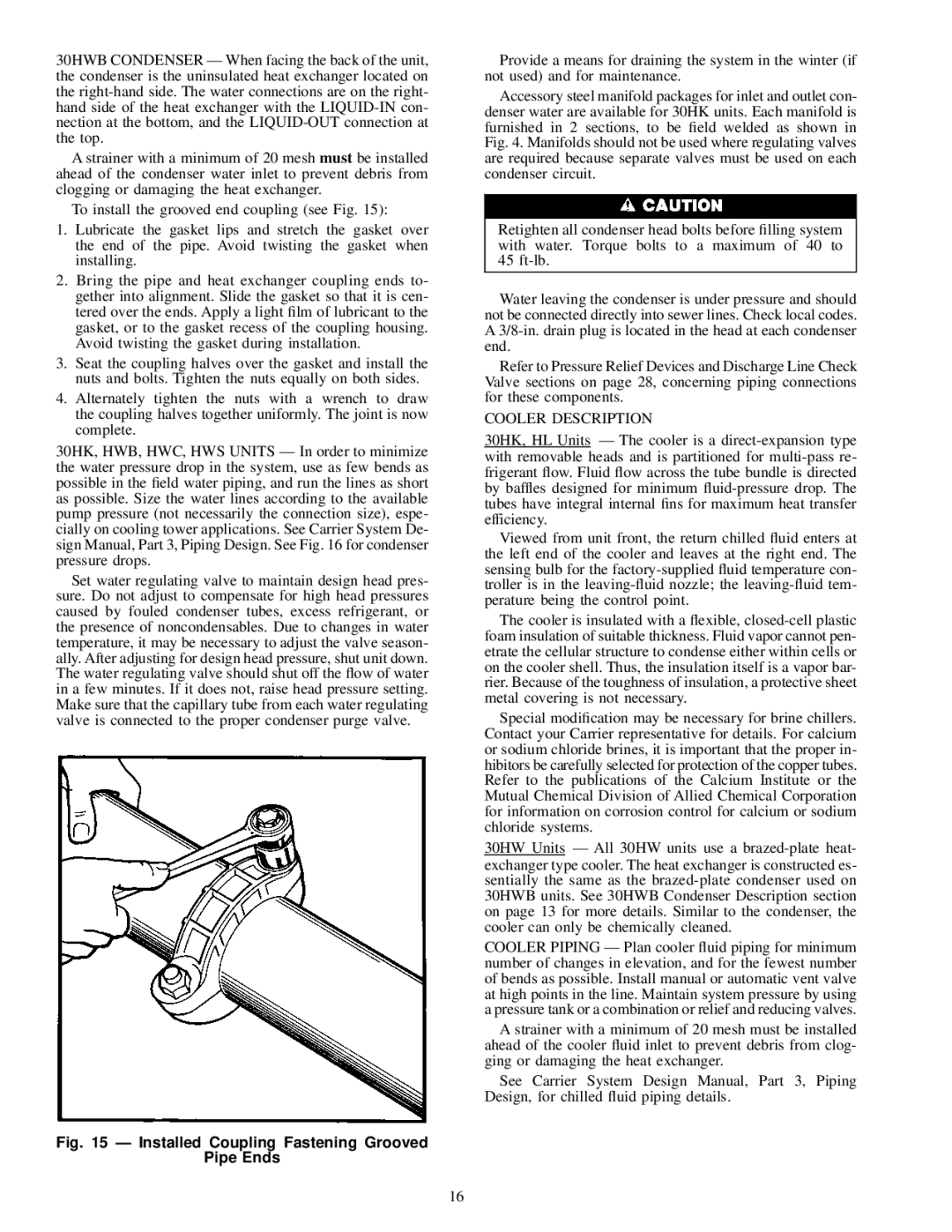

To install the grooved end coupling (see Fig. 15):

1.Lubricate the gasket lips and stretch the gasket over the end of the pipe. Avoid twisting the gasket when installing.

2.Bring the pipe and heat exchanger coupling ends to- gether into alignment. Slide the gasket so that it is cen- tered over the ends. Apply a light ®lm of lubricant to the gasket, or to the gasket recess of the coupling housing. Avoid twisting the gasket during installation.

3.Seat the coupling halves over the gasket and install the nuts and bolts. Tighten the nuts equally on both sides.

4.Alternately tighten the nuts with a wrench to draw the coupling halves together uniformly. The joint is now complete.

30HK, HWB, HWC, HWS UNITS Ð In order to minimize the water pressure drop in the system, use as few bends as possible in the ®eld water piping, and run the lines as short as possible. Size the water lines according to the available pump pressure (not necessarily the connection size), espe- cially on cooling tower applications. See Carrier System De- sign Manual, Part 3, Piping Design. See Fig. 16 for condenser pressure drops.

Set water regulating valve to maintain design head pres- sure. Do not adjust to compensate for high head pressures caused by fouled condenser tubes, excess refrigerant, or the presence of noncondensables. Due to changes in water temperature, it may be necessary to adjust the valve season- ally. After adjusting for design head pressure, shut unit down. The water regulating valve should shut off the ¯ow of water in a few minutes. If it does not, raise head pressure setting. Make sure that the capillary tube from each water regulating valve is connected to the proper condenser purge valve.

Fig. 15 Ð Installed Coupling Fastening Grooved

Pipe Ends

Provide a means for draining the system in the winter (if not used) and for maintenance.

Accessory steel manifold packages for inlet and outlet con- denser water are available for 30HK units. Each manifold is furnished in 2 sections, to be ®eld welded as shown in Fig. 4. Manifolds should not be used where regulating valves are required because separate valves must be used on each condenser circuit.

Retighten all condenser head bolts before ®lling system with water. Torque bolts to a maximum of 40 to 45 ft-lb.

Water leaving the condenser is under pressure and should not be connected directly into sewer lines. Check local codes. A 3/8-in. drain plug is located in the head at each condenser end.

Refer to Pressure Relief Devices and Discharge Line Check Valve sections on page 28, concerning piping connections for these components.

COOLER DESCRIPTION

30HK, HL Units Ð The cooler is a direct-expansion type with removable heads and is partitioned for multi-pass re- frigerant ¯ow. Fluid ¯ow across the tube bundle is directed by baffles designed for minimum ¯uid-pressure drop. The tubes have integral internal ®ns for maximum heat transfer efficiency.

Viewed from unit front, the return chilled ¯uid enters at the left end of the cooler and leaves at the right end. The sensing bulb for the factory-supplied ¯uid temperature con- troller is in the leaving-¯uid nozzle; the leaving-¯uid tem- perature being the control point.

The cooler is insulated with a ¯exible, closed-cell plastic foam insulation of suitable thickness. Fluid vapor cannot pen- etrate the cellular structure to condense either within cells or on the cooler shell. Thus, the insulation itself is a vapor bar- rier. Because of the toughness of insulation, a protective sheet metal covering is not necessary.

Special modi®cation may be necessary for brine chillers. Contact your Carrier representative for details. For calcium or sodium chloride brines, it is important that the proper in- hibitors be carefully selected for protection of the copper tubes. Refer to the publications of the Calcium Institute or the Mutual Chemical Division of Allied Chemical Corporation for information on corrosion control for calcium or sodium chloride systems.

30HW Units Ð All 30HW units use a brazed-plate heat- exchanger type cooler. The heat exchanger is constructed es- sentially the same as the brazed-plate condenser used on 30HWB units. See 30HWB Condenser Description section on page 13 for more details. Similar to the condenser, the cooler can only be chemically cleaned.

COOLER PIPING Ð Plan cooler ¯uid piping for minimum number of changes in elevation, and for the fewest number of bends as possible. Install manual or automatic vent valve at high points in the line. Maintain system pressure by using a pressure tank or a combination or relief and reducing valves.

A strainer with a minimum of 20 mesh must be installed ahead of the cooler ¯uid inlet to prevent debris from clog- ging or damaging the heat exchanger.

See Carrier System Design Manual, Part 3, Piping Design, for chilled ¯uid piping details.