At the upper right corner of the board is a set of 5 pins and jumper, which determines the time constant for the control. The time constant is the delay in response built into the con- trols. The jumper should be on the middle or bottom two pins, for the maximum time constant. The delay can be decreased, if desired, by moving the jumper progressively upward, always jumpering adjacent pins.

At the lower left corner of the board below the terminal strip is a resistor marked R27. This must be removed in order to obtain the 0 to 10 vdc signal output. There will not be a resistor on a factory-supplied module, but a resistor may be present on a replacement module and must be removed.

The R353 module has a terminal block with 7 connec- tions available for wiring. The 2 right-hand terminals are for the 24 vac and common connections. The next 2 terminals are for the 0 to 10 vdc signal. Consult the wiring label for wire identi®cation if replacing the module. The 3 left-hand terminals are not used for this application.

The S353 module has an LED (light-emitting diode), a set of 4 jumper pins, and 2 potentiometers. The LED will light whenever the module is activated, providing a visual indi- cation of the number of exhaust fans running. The jumper pins are arranged in a square format. Two jumpers are used to determine the mode of operation (direct or reverse). The 2 jumpers must be arranged horizontally for direct action (factory set).

At the top of the module are two potentiometers. The left potentiometer adjusts the offset. The right potentiometer adjusts the differential. The potentiometers are factory set for a nominal 0 in. wg building pressure.

The offset set point is de®ned as the point at which a mod- ule turns off a fan, and is measured in terms of percent of the input signal. For control purposes, 0 offset is at an arbitrary ``¯oor'' which is established at 10% of the input signal, or 1 vdc. In this example, the ®rst stage will turn off at 30% (3 vdc), and the offset potentiometer will be set at 20%. The second stage will turn off at 50% signal (5 vdc), and the offset potentiometer will be set at 40%. The fourth stage is at the maximum 75% offset, which equates to 85% signal or 8.5 vdc. The offset potentiometer is calibrated in 10% increments.

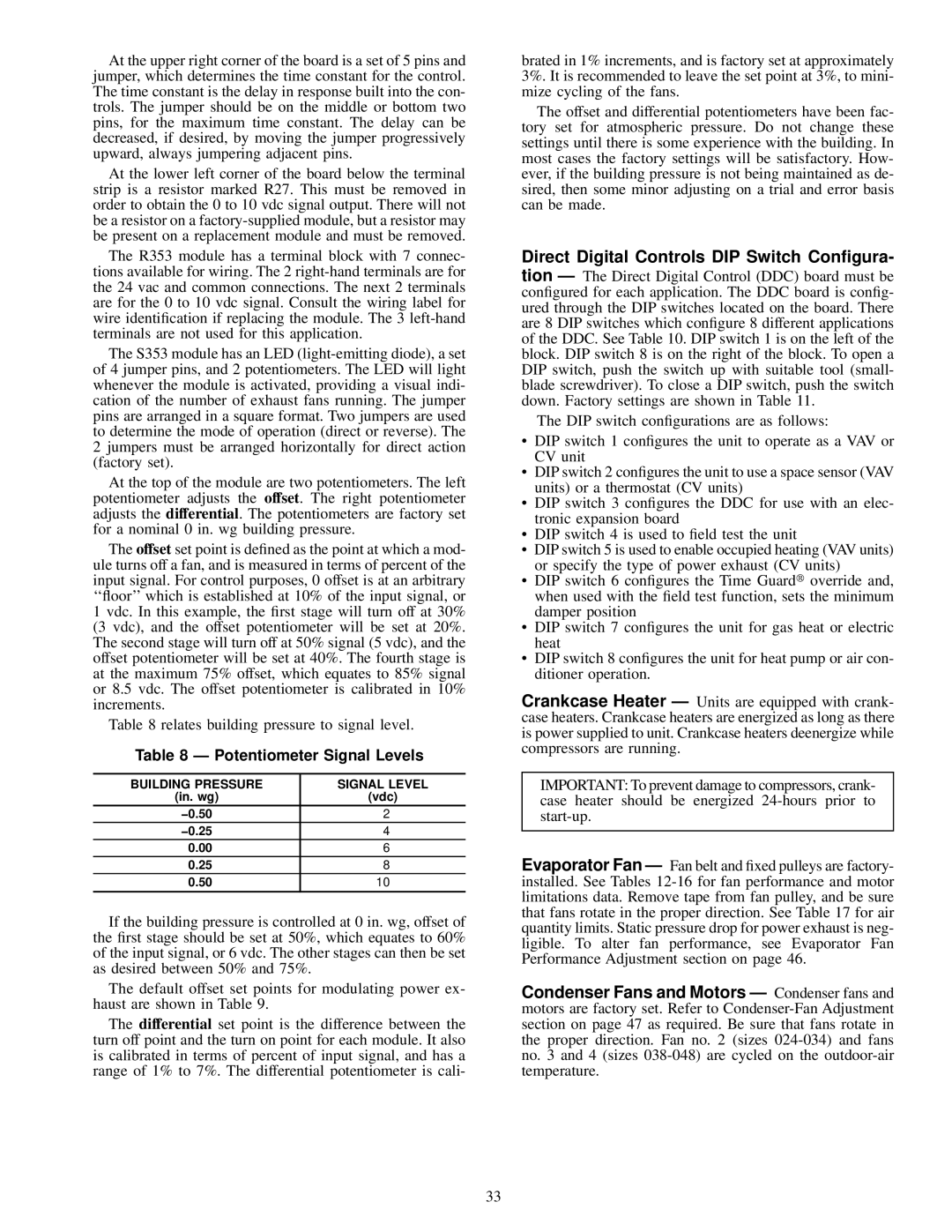

Table 8 relates building pressure to signal level.

Table 8 Ð Potentiometer Signal Levels

BUILDING PRESSURE | SIGNAL LEVEL |

(in. wg) | (vdc) |

−0.50 | 2 |

−0.25 | 4 |

0.00 | 6 |

0.25 | 8 |

0.50 | 10 |

| |

If the building pressure is controlled at 0 in. wg, offset of the ®rst stage should be set at 50%, which equates to 60% of the input signal, or 6 vdc. The other stages can then be set as desired between 50% and 75%.

The default offset set points for modulating power ex- haust are shown in Table 9.

The differential set point is the difference between the turn off point and the turn on point for each module. It also is calibrated in terms of percent of input signal, and has a range of 1% to 7%. The differential potentiometer is cali-

brated in 1% increments, and is factory set at approximately 3%. It is recommended to leave the set point at 3%, to mini- mize cycling of the fans.

The offset and differential potentiometers have been fac- tory set for atmospheric pressure. Do not change these settings until there is some experience with the building. In most cases the factory settings will be satisfactory. How- ever, if the building pressure is not being maintained as de- sired, then some minor adjusting on a trial and error basis can be made.

Direct Digital Controls DIP Switch Con®gura-

tion Ð The Direct Digital Control (DDC) board must be con®gured for each application. The DDC board is con®g- ured through the DIP switches located on the board. There are 8 DIP switches which con®gure 8 different applications of the DDC. See Table 10. DIP switch 1 is on the left of the block. DIP switch 8 is on the right of the block. To open a DIP switch, push the switch up with suitable tool (small- blade screwdriver). To close a DIP switch, push the switch down. Factory settings are shown in Table 11.

The DIP switch con®gurations are as follows:

·DIP switch 1 con®gures the unit to operate as a VAV or CV unit

·DIP switch 2 con®gures the unit to use a space sensor (VAV units) or a thermostat (CV units)

·DIP switch 3 con®gures the DDC for use with an elec- tronic expansion board

·DIP switch 4 is used to ®eld test the unit

·DIP switch 5 is used to enable occupied heating (VAV units) or specify the type of power exhaust (CV units)

· DIP switch 6 con®gures the Time Guard override and, when used with the ®eld test function, sets the minimum damper position

·DIP switch 7 con®gures the unit for gas heat or electric heat

·DIP switch 8 con®gures the unit for heat pump or air con- ditioner operation.

Crankcase Heater Ð Units are equipped with crank- case heaters. Crankcase heaters are energized as long as there is power supplied to unit. Crankcase heaters deenergize while compressors are running.

IMPORTANT: To prevent damage to compressors, crank- case heater should be energized 24-hours prior to start-up.

Evaporator Fan Ð Fan belt and ®xed pulleys are factory- installed. See Tables 12-16 for fan performance and motor limitations data. Remove tape from fan pulley, and be sure that fans rotate in the proper direction. See Table 17 for air quantity limits. Static pressure drop for power exhaust is neg- ligible. To alter fan performance, see Evaporator Fan Performance Adjustment section on page 46.

Condenser Fans and Motors Ð Condenser fans and motors are factory set. Refer to Condenser-Fan Adjustment section on page 47 as required. Be sure that fans rotate in the proper direction. Fan no. 2 (sizes 024-034) and fans no. 3 and 4 (sizes 038-048) are cycled on the outdoor-air temperature.