SAFETY

SETUP

BASIC

Maintenance

TO PREVENT SERIOUS INJURY, |

| Gun |

+ |

| |

FIRE AND BURNS: |

| |

Unplug the Welder, |

| |

rest the Gun on a |

| |

electrically | concrete slab | |

and allow all parts of the Welder to cool thoroughly | ||

|

| other |

before service. |

| surface) |

|

|

1.Periodically remove the Right and Left side panels, and using compressed air, blow out all dust from the interior.

2.Store in a clean and dry location.

3.For optimal weld quality, clean and inspect the Contact Tip and Nozzle before each use. See below.

Nozzle Inspection, Cleaning, and Replacement

WELDING

WELDING TIPS

MAINTENANCE

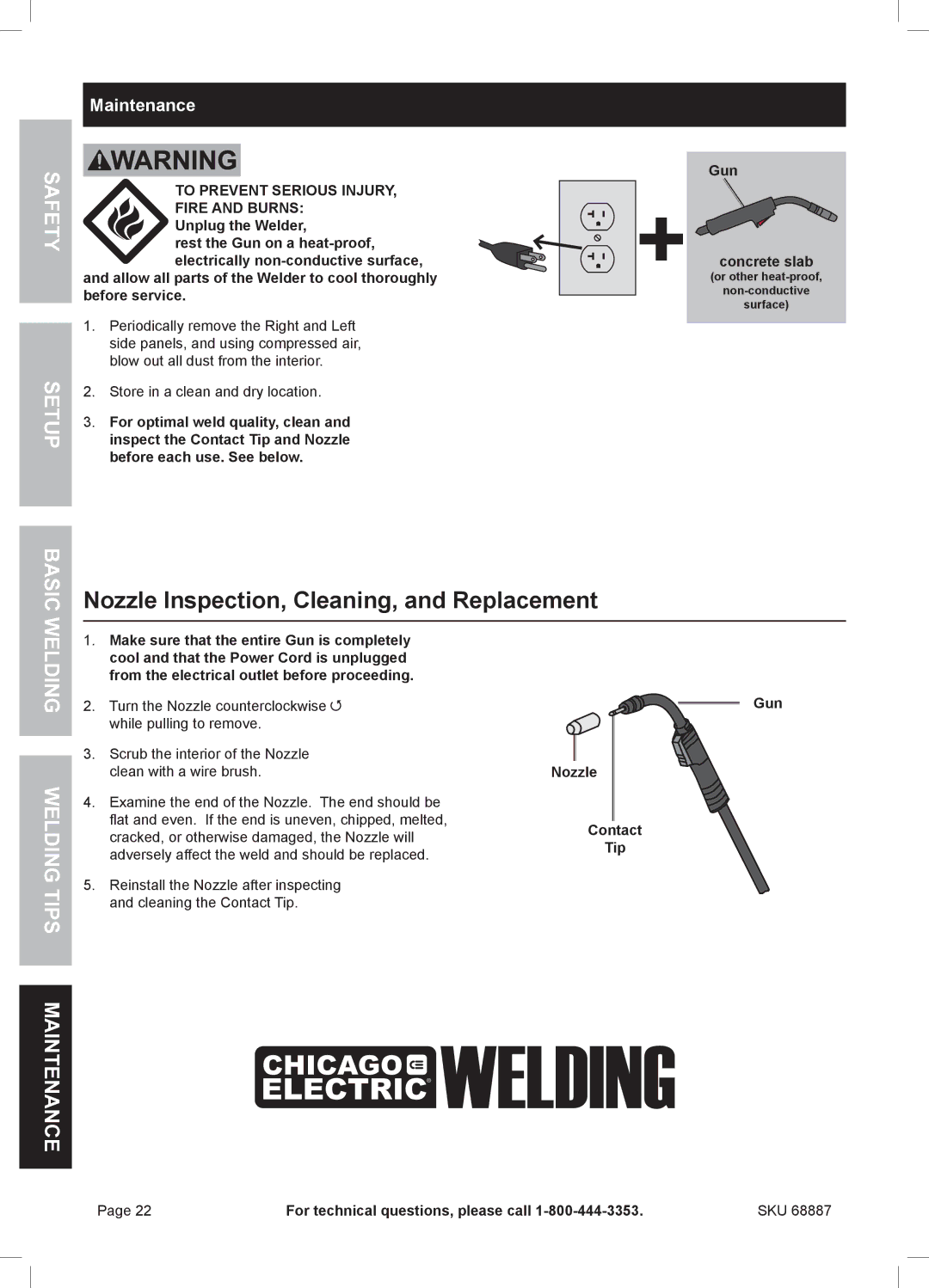

1.Make sure that the entire Gun is completely cool and that the Power Cord is unplugged from the electrical outlet before proceeding.

2.Turn the Nozzle counterclockwise ![]() while pulling to remove.

while pulling to remove.

3.Scrub the interior of the Nozzle clean with a wire brush.

4.Examine the end of the Nozzle. The end should be flat and even. If the end is uneven, chipped, melted, cracked, or otherwise damaged, the Nozzle will adversely affect the weld and should be replaced.

5.Reinstall the Nozzle after inspecting and cleaning the Contact Tip.

Gun

Nozzle

Contact

Tip

Page 22 | For technical questions, please call | SKU 68887 |