Setting Up The Weld

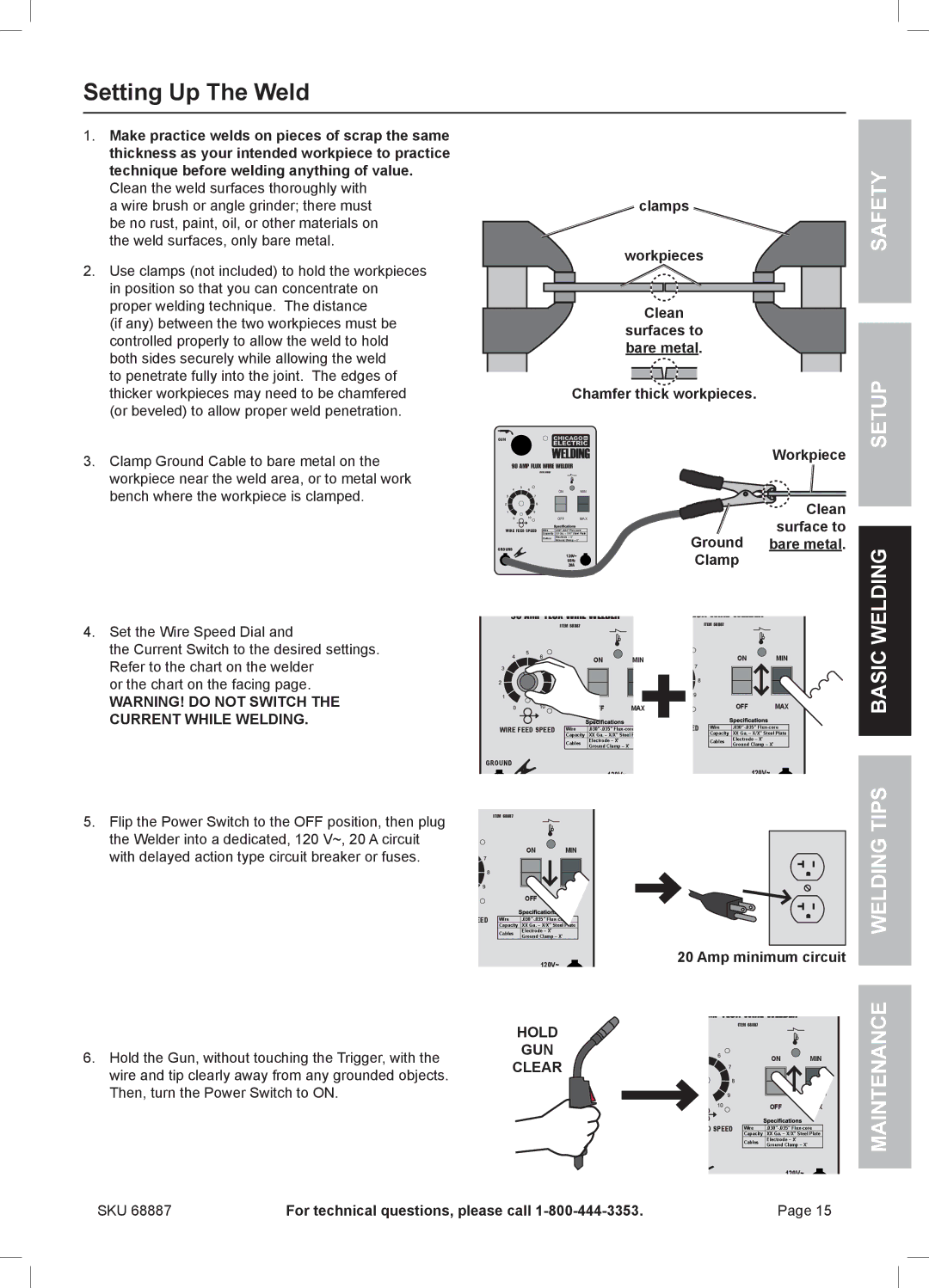

1. Make practice welds on pieces of scrap the same |

thickness as your intended workpiece to practice |

technique before welding anything of value. |

Clean the weld surfaces thoroughly with |

a wire brush or angle grinder; there must |

be no rust, paint, oil, or other materials on |

the weld surfaces, only bare metal. |

2. Use clamps (not included) to hold the workpieces |

in position so that you can concentrate on |

proper welding technique. The distance |

(if any) between the two workpieces must be |

controlled properly to allow the weld to hold |

both sides securely while allowing the weld |

to penetrate fully into the joint. The edges of |

thicker workpieces may need to be chamfered |

(or beveled) to allow proper weld penetration. |

clamps

workpieces

Clean

surfaces to bare metal.

Chamfer thick workpieces.

SAFETY

SETUP

3. Clamp Ground Cable to bare metal on the |

workpiece near the weld area, or to metal work |

bench where the workpiece is clamped. |

GUN

90 AMP FLUX WIRE WELDER

| ITEM 68887 |

|

|

| |

|

|

| ON | MIN | |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| OFF | MAX | |

WIRE FEED SPEED |

|

|

|

|

|

| Wire | ||||

| Capacity | XX Ga. – X/X″ Steel Plate | |||

|

| Cables | Electrode – X′ |

| |

|

| Ground Clamp – X′ |

| ||

GROUND

120V~ 60Hz 20A

90 AMP FLUX WIRE WELDER

Workpiece

![]()

![]() Clean surface to Ground bare metal.

Clean surface to Ground bare metal.

Clamp

LUX WIRE WELDER

WELDING

4. Set the Wire Speed Dial and |

the Current Switch to the desired settings. |

Refer to the chart on the welder |

or the chart on the facing page. |

WARNING! DO NOT SWITCH THE |

CURRENT WHILE WELDING. |

ITEM 68887 |

|

|

|

| ITEM 68887 |

|

|

| ON | MIN |

|

| ON | MIN | |

| OFF | MAX |

|

| OFF | MAX | |

WIRE FEED SPEED Wire |

| ED | Wire | ||||

| Capacity XX Ga. – X/X″ Steel Plate | ||||||

Capacity XX Ga. – X/X″ Steel P |

|

| |||||

+ Cables | Electrode – X′ |

| |||||

Cables | Electrode – X′ |

|

| ||||

Ground Clamp – X′ |

| Ground Clamp – X′ |

| ||||

GROUND |

|

|

|

|

|

|

|

| 120V~ |

|

|

|

| 120V~ |

|

BASIC

5.Flip the Power Switch to the OFF position, then plug the Welder into a dedicated, 120 V~, 20 A circuit with delayed action type circuit breaker or fuses.

P FLUX WIRE WELDER

| ITEM 68887 |

|

|

|

| ON | MIN |

|

| OFF | MAX |

SPEED | Wire | ||

| Capacity XX Ga. – X/X″ Steel Plate | ||

| Cables | Electrode – X′ |

|

| Ground Clamp – X′ |

| |

|

|

| |

120V~

60Hz

20 Amp minimum circuit

WELDING TIPS

| HOLD | |

6. Hold the Gun, without touching the Trigger, with the | GUN | |

CLEAR | ||

wire and tip clearly away from any grounded objects. | ||

| ||

Then, turn the Power Switch to ON. |

|

SKU 68887 | For technical questions, please call |

MP FLUX WIRE WELDER

| ITEM 68887 |

|

|

|

| ON | MIN |

|

| OFF | MAX |

ED SPEED | Wire | ||

| Capacity XX Ga. – X/X″ Steel Plate | ||

| Cables | Electrode – X′ |

|

| Ground Clamp – X′ |

| |

|

|

| |

120V~

Page 15

MAINTENANCE