Contents

Page

General Safety

Table of Contents

Fumes and Gases can be hazardous to your health

Fume and Gas Safety

Arc Ray Safety

Safety

Welding Welding Tips Maintenance

Electrical Safety

Fire Safety

Safety Setup

Welder use and care

Maintenance

Extension Cords

Tips Maintenance

Symbology

Grounded Welders

To Prevent Serious Injury from Accidental Operation

Cover Assembly

Specifications

Setup

Setup Basic Welding

Wire Spool Installation

Spindle

Hold Wire

Basic Welding Welding Tips Maintenance

Back into the Gun

Wire Liner may come out with the welding

Wire, this is normal, just push the Wire Liner

Gun Welding Wire For technical questions, please call

Gun Nozzle Contact Tip

Setup Basic Welding Welding Tips Maintenance

Incrementally Increase tension Until Wire bends

Turn the Welder to OFF

To Prevent Serious Injury

Basic Welding

To Prevent Serious INJURY, Fire and Burns

Control Panel Layout

Safety Setup Basic Welding Welding Tips Maintenance

Gun Concrete slab

Weld Settings Chart

Wire size and material thickness

Duty Cycle Duration of Use

Welding

Setting Up The Weld

Basic Welding Technique

Safety

Hold GUN Clear

Up to 2 minutes welding At rated output

Strike Test

Cleaning the Weld

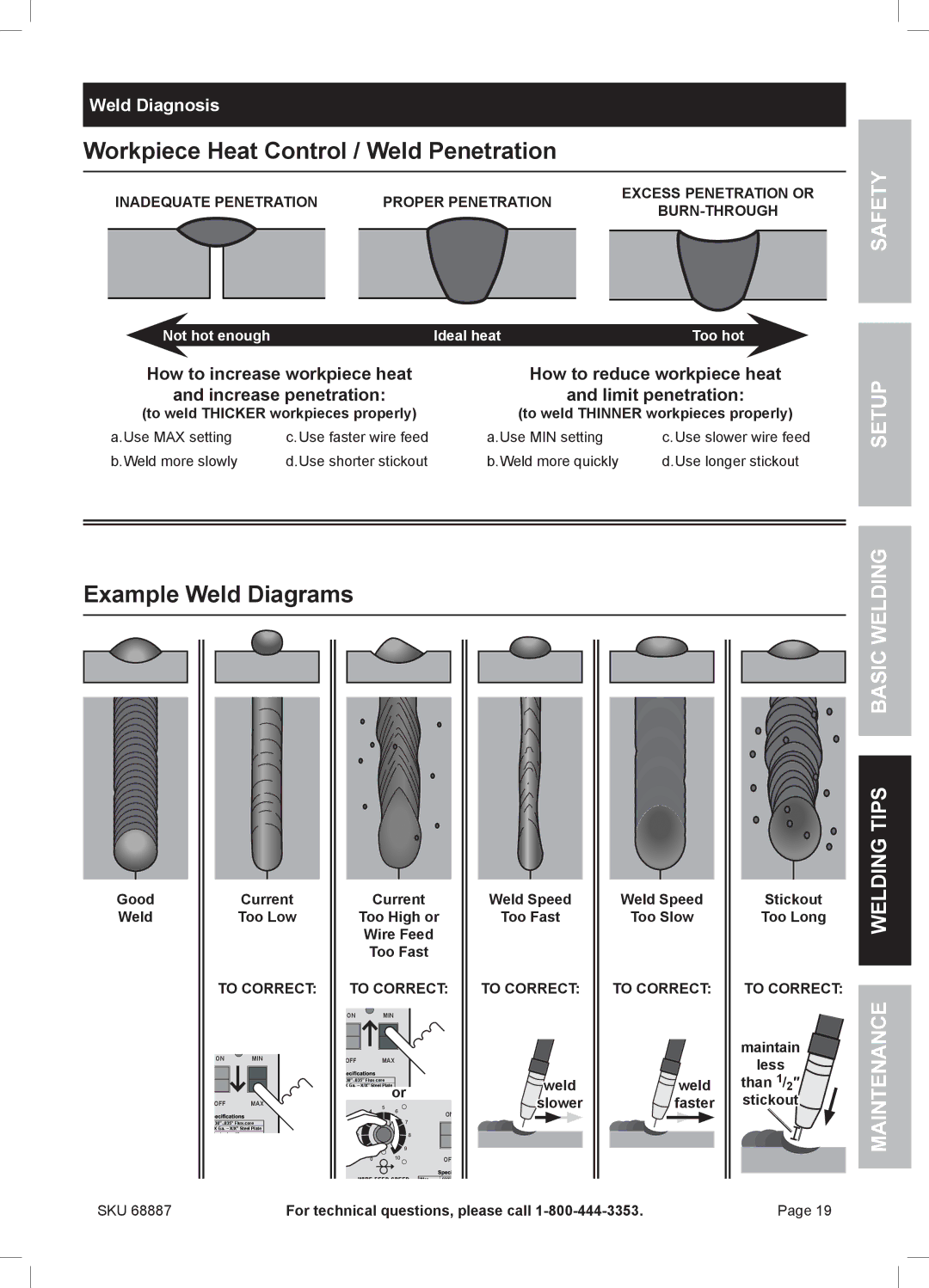

Welding Tips

To Correct

Example Weld Diagrams

Workpiece Heat Control / Weld Penetration

Weld Diagnosis

Weld Not Adhering Properly

Weld Problems

Possible Causes and Solutions

Penetration Workpiece Heat Control

Excessive Spatter

Coat of Slag Over Weld

Porosity

Crooked/Wavy Bead

Fire and Burns

Nozzle Inspection, Cleaning, and Replacement

Safety Setup Basic

Maintenance

Nozzle Contact Tip Gun

Contact Tip Inspection, Cleaning, and Replacement

Troubleshooting

Wire Feed Motor Runs But Wire Does Not Feed Properly

Wire Creates a Bird’s Nest During Operation

Wire Feeds, But Arc Does Not Ignite

Welding Arc Not Stable

Troubleshooting

Power Switch Does Not Light When Switched On

Weak Arc Strength

Parts List

Wiring Schematic

Parts Lists and Diagrams

Record Product’s Serial Number Here

Assembly Diagram Part 9 Detail

Mission Oaks Blvd. PO Box 6009 Camarillo, CA 93011 800

Limited 90 Day Warranty