Contact Tip Inspection, Cleaning, and Replacement

1.Make sure that the entire Gun is completely cool and that the Power Cord is unplugged from the electrical outlet before proceeding.

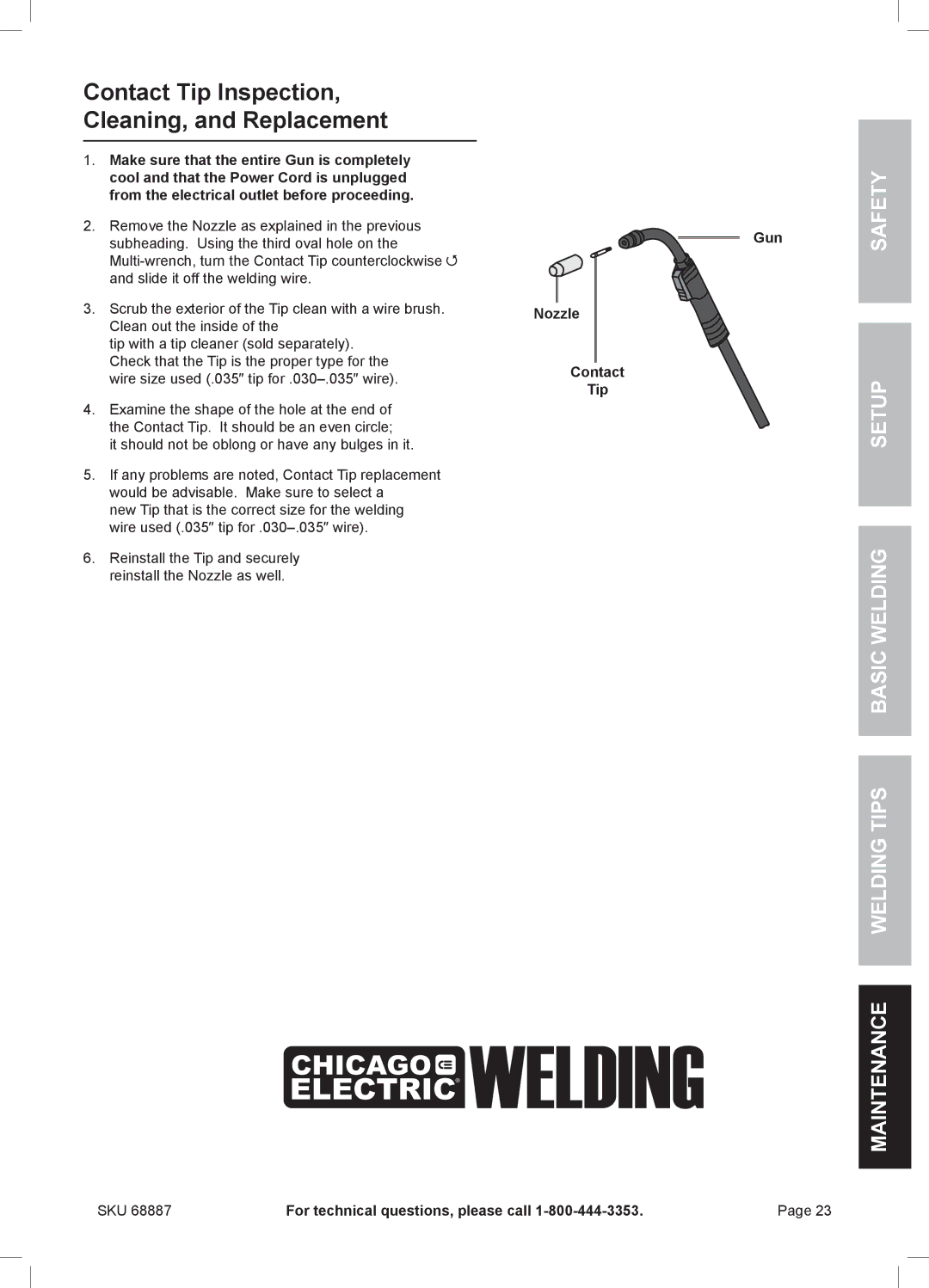

2.Remove the Nozzle as explained in the previous subheading. Using the third oval hole on the Multi‑wrench, turn the Contact Tip counterclockwise ![]() and slide it off the welding wire.

and slide it off the welding wire.

3.Scrub the exterior of the Tip clean with a wire brush. Clean out the inside of the

tip with a tip cleaner (sold separately). Check that the Tip is the proper type for the wire size used (.035″ tip

4.Examine the shape of the hole at the end of the Contact Tip. It should be an even circle;

it should not be oblong or have any bulges in it.

5.If any problems are noted, Contact Tip replacement would be advisable. Make sure to select a

new Tip that is the correct size for the welding wire used (.035″ tip

6.Reinstall the Tip and securely reinstall the Nozzle as well.

Nozzle

Contact

Tip

Gun

SAFETY

SETUP

BASIC WELDING

WELDING TIPS

MAINTENANCE

SKU 68887 | For technical questions, please call |

Page 23