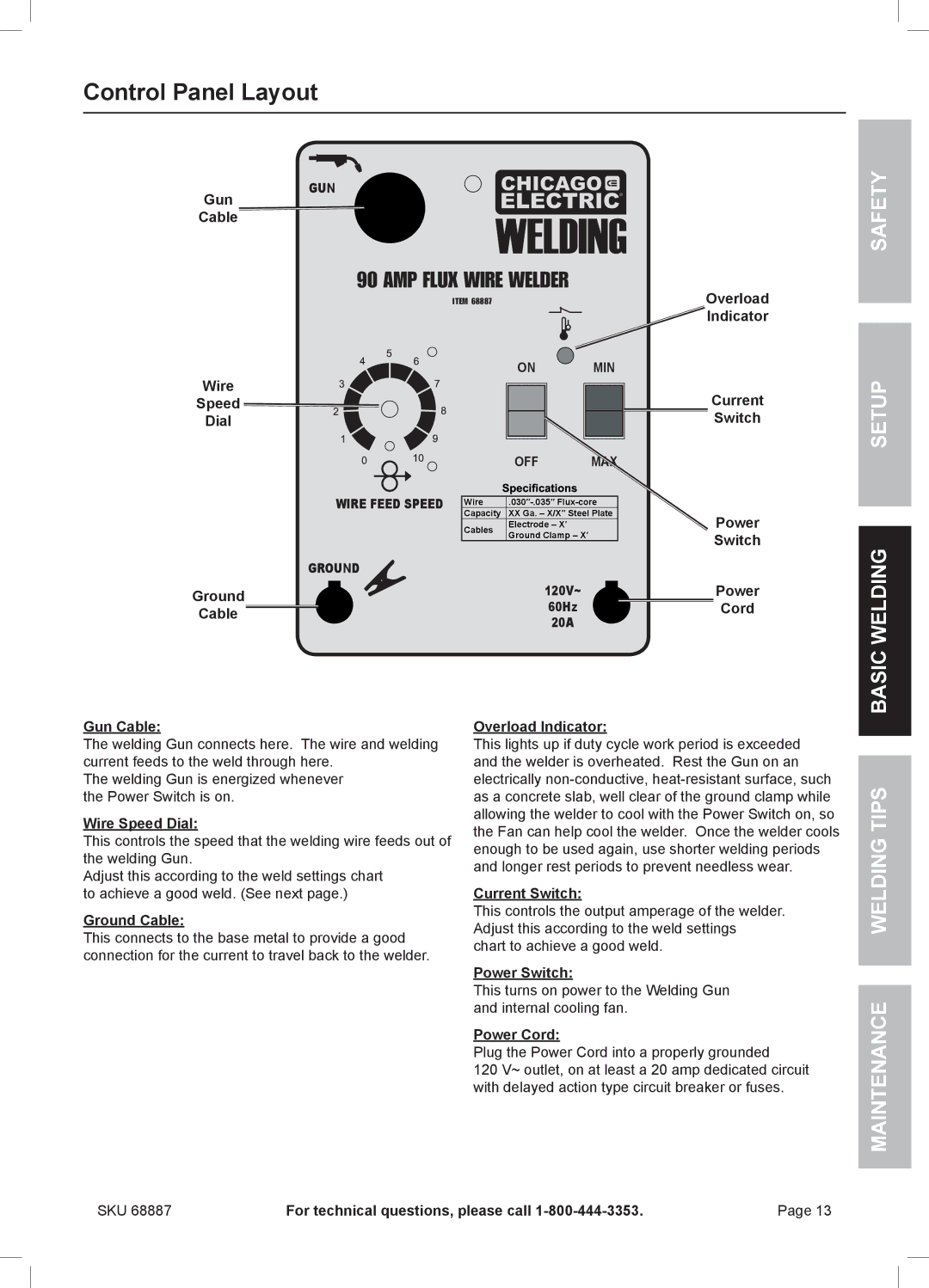

Control Panel Layout

Gun

GUN

Cable

90 AMP FLUX WIRE WELDER

ITEM 68887

ON

Wire

Speed

Dial

OFF

Overload

Indicator

MIN

Current

Switch

MAX

WIRE FEED SPEED

GROUND

Ground

Cable

Wire |

Capacity XX Ga. – X/X″ Steel Plate

Cables | Electrode – X′ | |

Ground Clamp – X′ | ||

|

120V~

60Hz

20A

Power Switch

Power

Cord

Gun Cable:

The welding Gun connects here. The wire and welding current feeds to the weld through here.

The welding Gun is energized whenever the Power Switch is on.

Wire Speed Dial:

This controls the speed that the welding wire feeds out of the welding Gun.

Adjust this according to the weld settings chart to achieve a good weld. (See next page.)

Ground Cable:

This connects to the base metal to provide a good connection for the current to travel back to the welder.

Overload Indicator:

This lights up if duty cycle work period is exceeded and the welder is overheated. Rest the Gun on an electrically

Current Switch:

This controls the output amperage of the welder. Adjust this according to the weld settings chart to achieve a good weld.

Power Switch:

This turns on power to the Welding Gun and internal cooling fan.

Power Cord:

Plug the Power Cord into a properly grounded

120 V~ outlet, on at least a 20 amp dedicated circuit with delayed action type circuit breaker or fuses.

SAFETY

SETUP

BASIC WELDING

WELDING TIPS

MAINTENANCE

SKU 68887 | For technical questions, please call | Page 13 |