|

|

|

|

| 36.70" |

|

|

|

|

| 2.52" | 1.58" | 1.82" |

| |

|

|

|

|

|

|

| |

|

| 44.98" | 38.98" |

|

|

|

|

|

|

| 6.00" |

|

|

| |

|

|

|

|

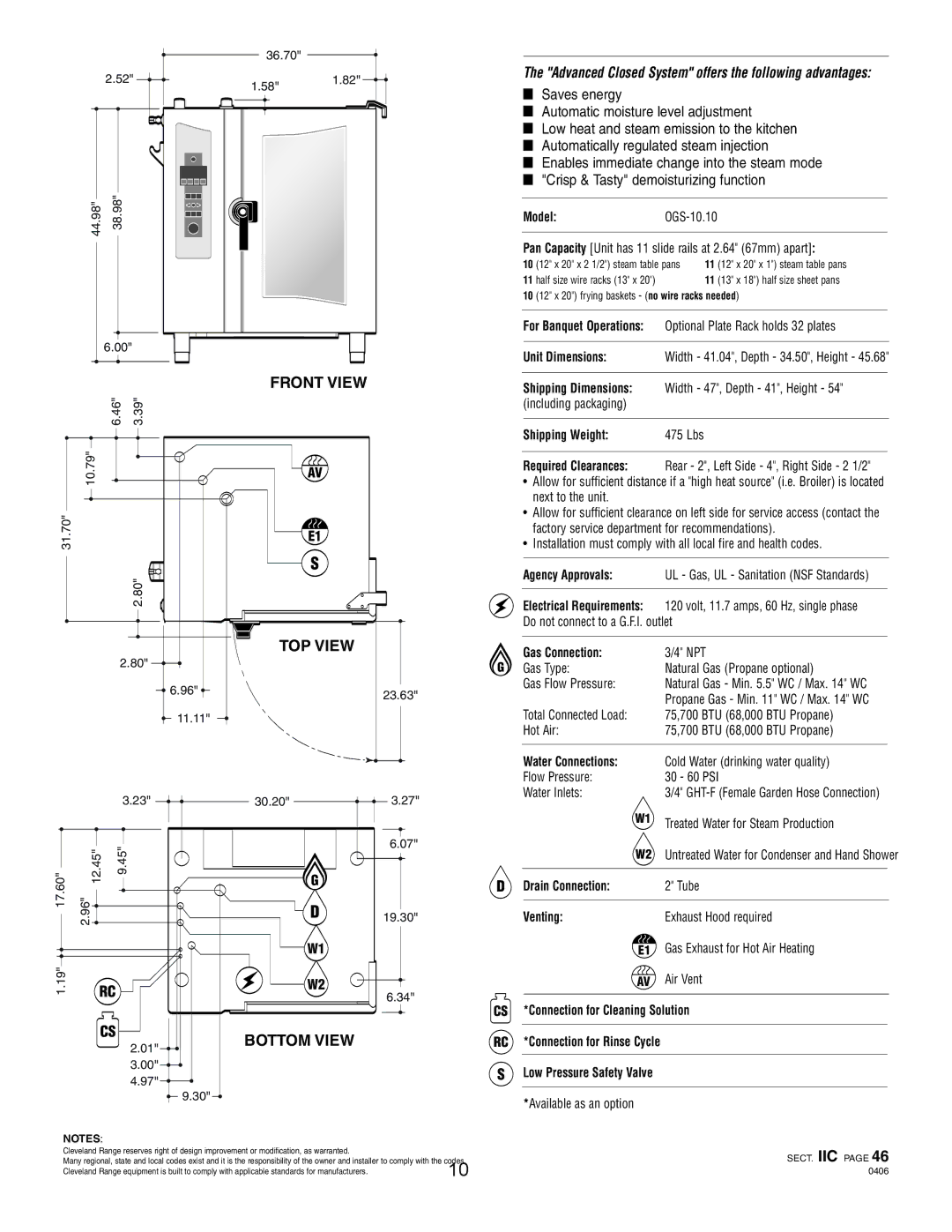

| FRONT VIEW |

| |

|

|

| 6.46" | 3.39" |

|

|

|

| 10.79" |

|

|

| AV |

| |

|

|

|

|

|

|

| |

31.70" |

|

|

|

|

| E1 |

|

|

|

|

|

|

|

| |

|

|

|

|

|

| S |

|

|

|

|

| 2.80" |

|

|

|

|

|

|

|

| TOP VIEW |

| |

|

|

| 2.80" |

|

|

| |

|

|

|

|

| 6.96" |

| 23.63" |

|

|

|

|

|

|

| |

|

|

|

|

| 11.11" |

|

|

|

|

|

| 3.23" | 30.20" |

| 3.27" |

17.60" |

| 12.45" | 9.45" |

|

| 6.07" | |

2.96" |

| D | 19.30" | ||||

|

|

|

|

|

| G |

|

1.19" |

|

|

|

|

| W1 |

|

| RC |

|

| W2 | 6.34" | ||

|

|

|

| ||||

|

|

|

|

| |||

|

| CS |

| BOTTOM VIEW |

| ||

|

|

|

| 2.01" |

| ||

|

|

|

|

|

|

| |

|

|

|

| 3.00" |

|

|

|

|

|

|

| 4.97" |

|

|

|

|

|

|

|

| 9.30" |

|

|

NOTES: |

|

|

|

|

| ||

The "Advanced Closed System" offers the following advantages:

■Saves energy

■Automatic moisture level adjustment

■Low heat and steam emission to the kitchen

■Automatically regulated steam injection

■Enables immediate change into the steam mode

■"Crisp & Tasty" demoisturizing function

Model:OGS-10.10

Pan Capacity [Unit has 11 slide rails at 2.64" (67mm) apart]:

10 | (12" x 20" x 2 1/2") steam table pans | 11 | (12" x 20" x 1") steam table pans |

11 half size wire racks (13" x 20") | 11 | (13" x 18") half size sheet pans | |

10 | (12" x 20") frying baskets - (no wire racks needed) | ||

|

|

|

|

For Banquet Operations: Optional Plate Rack holds 32 plates

Unit Dimensions: Width - 41.04", Depth - 34.50", Height - 45.68"

Shipping Dimensions: Width - 47", Depth - 41", Height - 54" (including packaging)

Shipping Weight: | 475 Lbs |

Required Clearances: Rear - 2", Left Side - 4", Right Side - 2 1/2"

•Allow for sufficient distance if a "high heat source" (i.e. Broiler) is located next to the unit.

•Allow for sufficient clearance on left side for service access (contact the factory service department for recommendations).

•Installation must comply with all local fire and health codes.

| Agency Approvals: | UL - Gas, UL - Sanitation (NSF Standards) | |||||

|

|

|

|

|

| ||

| Electrical Requirements: | 120 volt, 11.7 amps, 60 Hz, single phase | |||||

| Do not connect to a G.F.I. outlet | ||||||

|

|

|

|

|

| ||

G | Gas Connection: | 3/4" NPT | |||||

Gas Type: | Natural Gas (Propane optional) | ||||||

| Gas Flow Pressure: | Natural Gas - Min. 5.5" WC / Max. 14" WC | |||||

|

|

|

|

| Propane Gas - Min. 11" WC / Max. 14" WC | ||

| Total Connected Load: | 75,700 BTU (68,000 BTU Propane) | |||||

| Hot Air: | 75,700 BTU (68,000 BTU Propane) | |||||

|

|

|

|

|

| ||

| Water Connections: | Cold Water (drinking water quality) | |||||

| Flow Pressure: | 30 - 60 PSI | |||||

| Water Inlets: | 3/4" | |||||

|

|

| W1 | Treated Water for Steam Production | |||

|

|

| W2 | Untreated Water for Condenser and Hand Shower | |||

D |

|

|

|

|

| ||

Drain Connection: | 2" Tube | ||||||

|

|

|

|

| |||

| Venting: | Exhaust Hood required | |||||

|

|

| E1 | Gas Exhaust for Hot Air Heating | |||

|

|

|

|

| Air Vent | ||

|

|

| AV | ||||

|

|

|

| ||||

CS | *Connection for Cleaning Solution | ||||||

|

|

|

|

|

| ||

RC | *Connection for Rinse Cycle |

|

|

| |||

|

|

|

|

|

|

|

|

SLow Pressure Safety Valve *Available as an option

Cleveland Range reserves right of design improvement or modification, as warranted. |

| SECT. IIC PAGE 46 |

Many regional, state and local codes exist and it is the responsibility of the owner and installer to comply with the codes. | ||

Cleveland Range equipment is built to comply with applicable standards for manufacturers. | 10 | 0406 |

| ||