BEVEL STOP ADJUSTMENTS (FIG. O, P, Q)

!WARNING

To avoid injury from unexpected starting or electrical shock, make sure the trigger is released and remove the power cord from the power source.

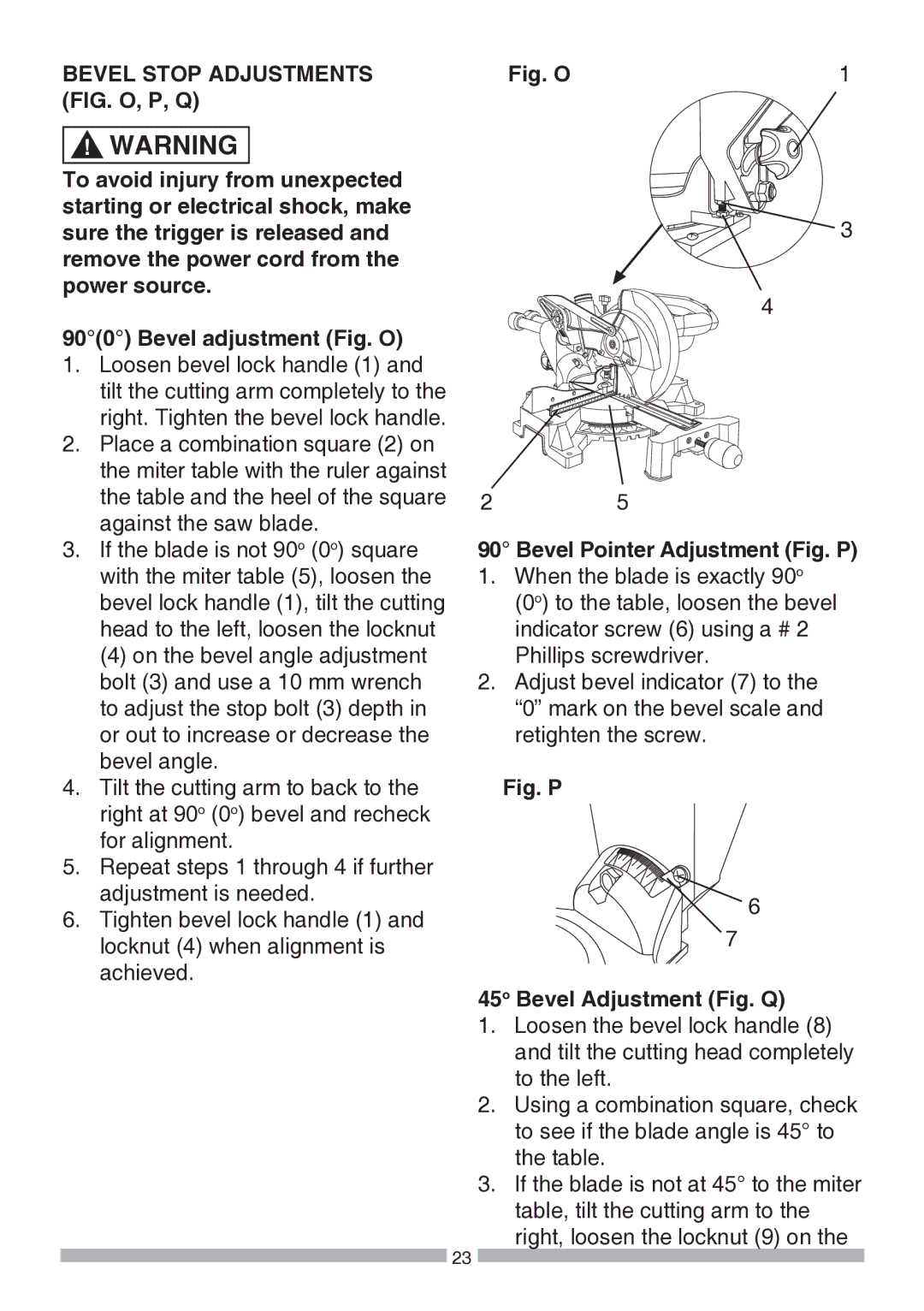

90°(0°) Bevel adjustment (Fig. O)

1.Loosen bevel lock handle (1) and tilt the cutting arm completely to the right. Tighten the bevel lock handle.

2.Place a combination square (2) on the miter table with the ruler against the table and the heel of the square against the saw blade.

3.If the blade is not 90o (0o) square with the miter table (5), loosen the bevel lock handle (1), tilt the cutting head to the left, loosen the locknut

(4) on the bevel angle adjustment bolt (3) and use a 10 mm wrench to adjust the stop bolt (3) depth in or out to increase or decrease the bevel angle.

4.Tilt the cutting arm to back to the right at 90o (0o) bevel and recheck for alignment.

5.Repeat steps 1 through 4 if further adjustment is needed.

6.Tighten bevel lock handle (1) and locknut (4) when alignment is achieved.

Fig. O | 1 |

3

4

25

90° Bevel Pointer Adjustment (Fig. P)

1.When the blade is exactly 90o

(0o) to the table, loosen the bevel indicator screw (6) using a # 2 Phillips screwdriver.

2.Adjust bevel indicator (7) to the “0” mark on the bevel scale and retighten the screw.

Fig. P

6

7

45o Bevel Adjustment (Fig. Q)

1.Loosen the bevel lock handle (8) and tilt the cutting head completely to the left.

2.Using a combination square, check to see if the blade angle is 45° to the table.

3.If the blade is not at 45° to the miter table, tilt the cutting arm to the right, loosen the locknut (9) on the

![]() 23

23 ![]()