Gear Case

•The gear case is lubricated with grease at the factory and does not require checking. If disassembled for any reason, lubricate with two ounces of Shell Alvania grease.

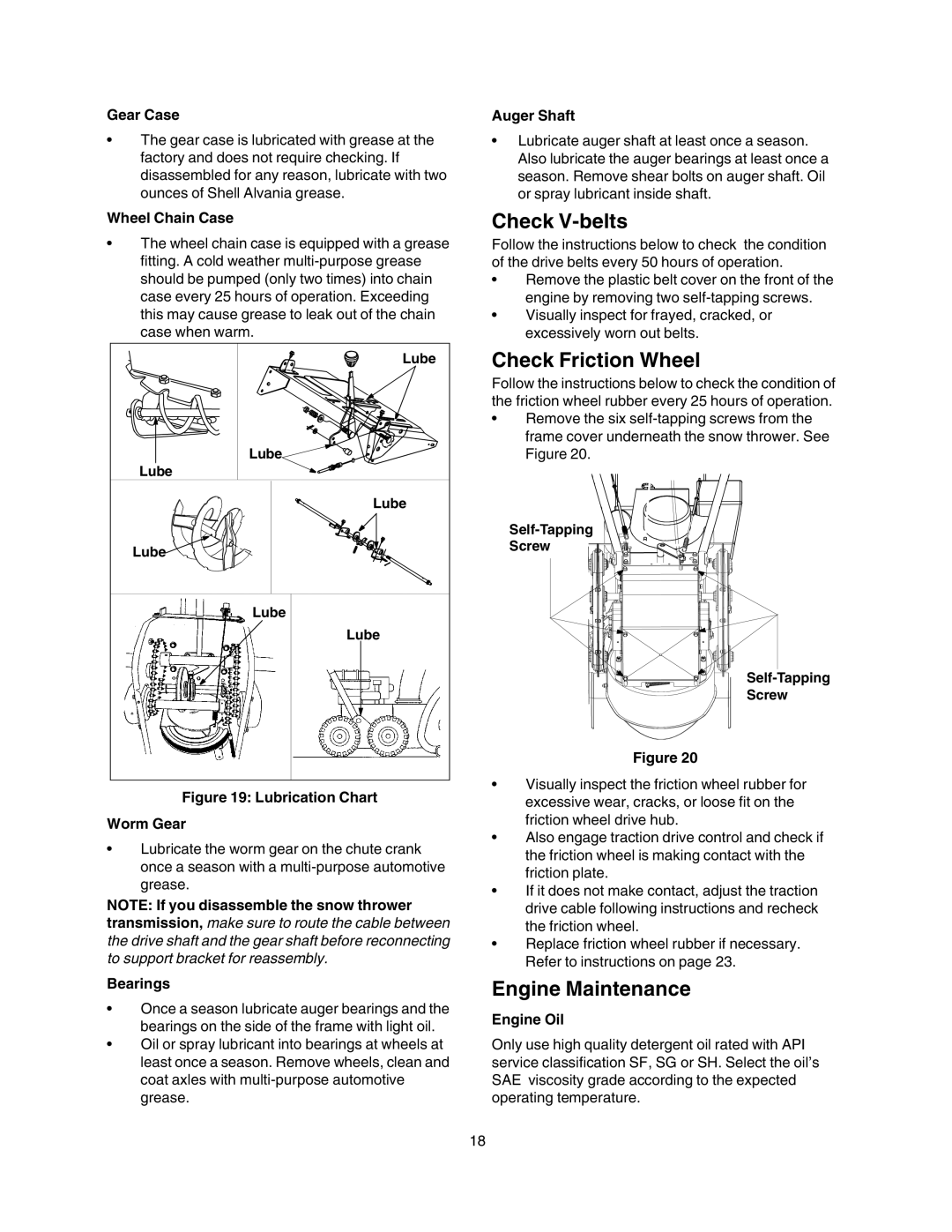

Wheel Chain Case

•The wheel chain case is equipped with a grease fitting. A cold weather

Lube |

Lube |

Lube |

Lube |

Lube |

Lube |

Lube |

Figure 19: Lubrication Chart

Worm Gear

•Lubricate the worm gear on the chute crank once a season with a

NOTE: If you disassemble the snow thrower transmission, make sure to route the cable between the drive shaft and the gear shaft before reconnecting to support bracket for reassembly.

Bearings

•Once a season lubricate auger bearings and the bearings on the side of the frame with light oil.

•Oil or spray lubricant into bearings at wheels at least once a season. Remove wheels, clean and coat axles with

Auger Shaft

•Lubricate auger shaft at least once a season. Also lubricate the auger bearings at least once a season. Remove shear bolts on auger shaft. Oil or spray lubricant inside shaft.

Check V-belts

Follow the instructions below to check the condition of the drive belts every 50 hours of operation.

•Remove the plastic belt cover on the front of the engine by removing two

•Visually inspect for frayed, cracked, or excessively worn out belts.

Check Friction Wheel

Follow the instructions below to check the condition of the friction wheel rubber every 25 hours of operation.

•Remove the six

Screw

Screw

Figure 20

•Visually inspect the friction wheel rubber for excessive wear, cracks, or loose fit on the friction wheel drive hub.

•Also engage traction drive control and check if the friction wheel is making contact with the friction plate.

•If it does not make contact, adjust the traction drive cable following instructions and recheck the friction wheel.

•Replace friction wheel rubber if necessary. Refer to instructions on page 23.

Engine Maintenance

Engine Oil

Only use high quality detergent oil rated with API service classification SF, SG or SH. Select the oil’s SAE viscosity grade according to the expected operating temperature.

18