Installation & Operation Manual

4 Sidewall direct venting (continued)

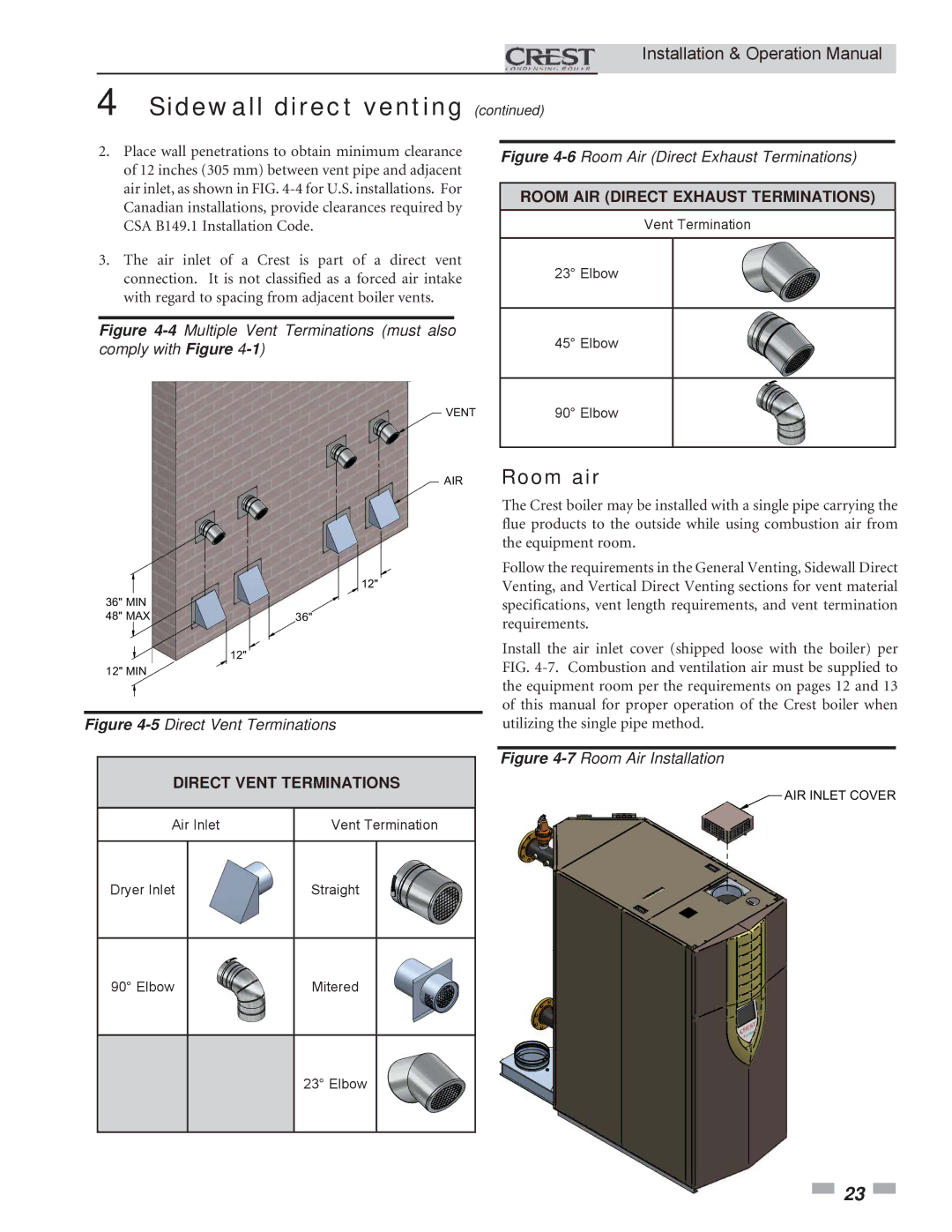

2.Place wall penetrations to obtain minimum clearance of 12 inches (305 mm) between vent pipe and adjacent air inlet, as shown in FIG.

3.The air inlet of a Crest is part of a direct vent connection. It is not classified as a forced air intake with regard to spacing from adjacent boiler vents.

Figure 4-4 Multiple Vent Terminations (must also comply with Figure 4-1)

| VENT |

| AIR |

| 12" |

36" MIN |

|

48" MAX | 36" |

| 12" |

12" MIN |

|

Figure 4-5 Direct Vent Terminations

DIRECT VENT TERMINATIONS

Air Inlet | Vent Termination |

Dryer Inlet | Straight |

Figure 4-6 Room Air (Direct Exhaust Terminations)

ROOM AIR (DIRECT EXHAUST TERMINATIONS)

Vent Termination

23° Elbow

45° Elbow

90° Elbow

Room air

The Crest boiler may be installed with a single pipe carrying the flue products to the outside while using combustion air from the equipment room.

Follow the requirements in the General Venting, Sidewall Direct Venting, and Vertical Direct Venting sections for vent material specifications, vent length requirements, and vent termination requirements.

Install the air inlet cover (shipped loose with the boiler) per FIG.

Figure 4-7 Room Air Installation

AIR INLET COVER

90° Elbow

Mitered

23° Elbow

![]() 23

23 ![]()