ADJUSTING TABLE SQUARE WITH SANDING DISC

1.DISCONNECT MACHINE FROM POWER SOURCE.

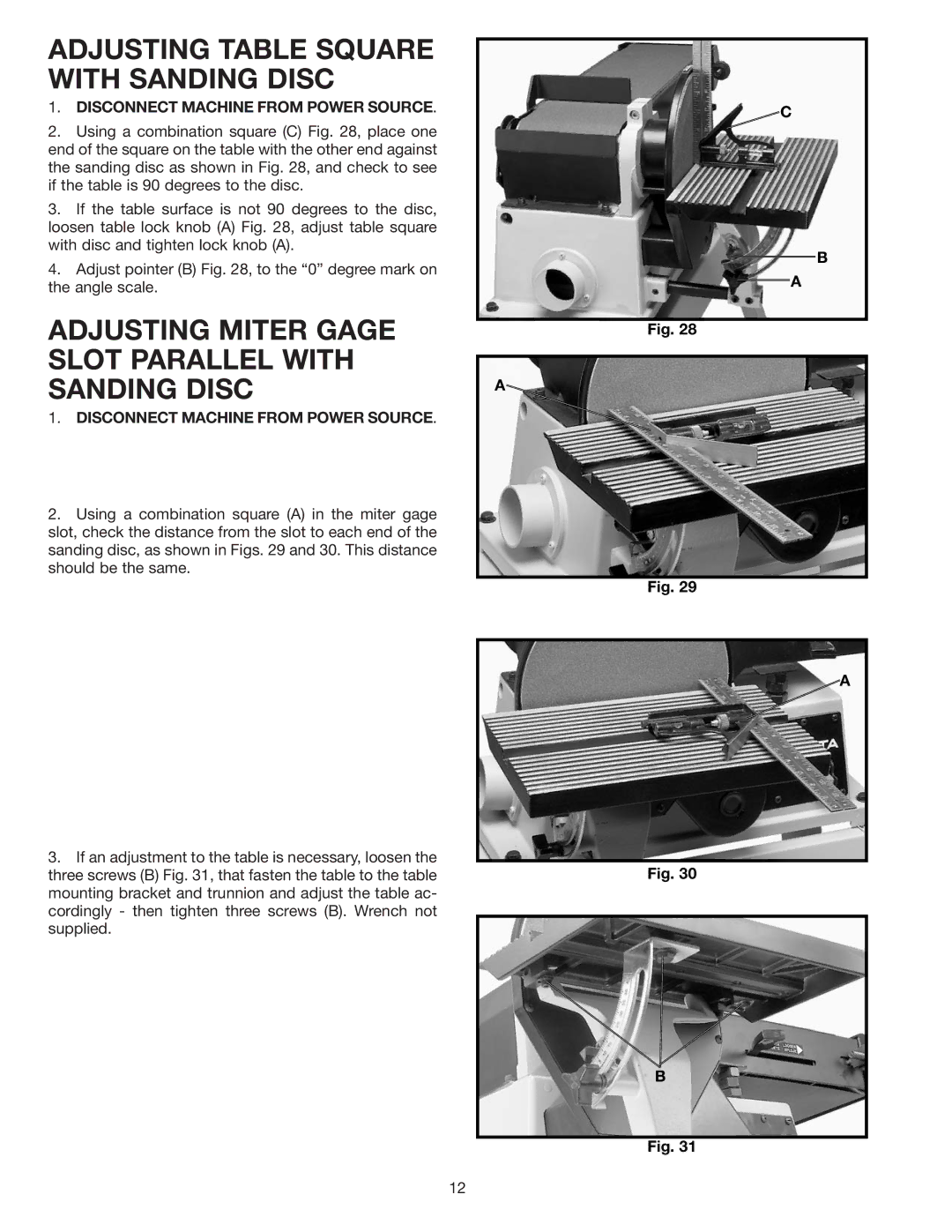

2.Using a combination square (C) Fig. 28, place one end of the square on the table with the other end against the sanding disc as shown in Fig. 28, and check to see if the table is 90 degrees to the disc.

3.If the table surface is not 90 degrees to the disc, loosen table lock knob (A) Fig. 28, adjust table square with disc and tighten lock knob (A).

4.Adjust pointer (B) Fig. 28, to the “0” degree mark on the angle scale.

ADJUSTING MITER GAGE SLOT PARALLEL WITH SANDING DISC

1.DISCONNECT MACHINE FROM POWER SOURCE.

2.Using a combination square (A) in the miter gage slot, check the distance from the slot to each end of the sanding disc, as shown in Figs. 29 and 30. This distance should be the same.

3.If an adjustment to the table is necessary, loosen the three screws (B) Fig. 31, that fasten the table to the table mounting bracket and trunnion and adjust the table ac- cordingly - then tighten three screws (B). Wrench not supplied.

![]() C

C

B

A

Fig. 28

A

Fig. 29

A

Fig. 30

B

Fig. 31

12