Page

Using This Manual „ Contents of this manual

„ Important precautions

„ Who should use this manual

This page intentionally left blank

Table of Contents

Chapter Macro Function

Revision Apr th, 2007, 2007PDD23000002

About this Manual… User Information

Technical Support and Service

DOP Series Human Machine Interface

Features

„ Support Multiple PLC’s Connections

„ Using SM Card to Backup Data

„ Simulation Function Note

„ Multiple Security Protection

DOP

Ordering Information

„ Operation Environment temperature and humidity

„ SM Card

„ USB Flash Drive

ScrEdit Screen Editor Setup

„ Software installation

„ Minimum System Requirement

Revision Apr th, 2007, 2007PDD23000002

5 Starting ScrEdit installation

Revision Apr th, 2007, 2007PDD23000002

2 Start-up display

How to Start ScrEdit

Revision Apr th, 2007, 2007PDD23000002

„ Menu Bar

„ Toolbar

Standard Toolbar Zoom Toolbar

6 ScrEdit Toolbar

„ Property Table

7 Move ScrEdit toolbar to the left side of the screen

„ Output Window

9 Editing screen preview

11 ScrEdit Work Place

„ Work Place

„ File

Menu Bar and Toolbar File

„ Create a New Project

„ Open Old Project

4 HMI model and base port controller options

„ Close File

„ Save File

„ Save As

„ Make Ext. Memory Data

8 Error message dialog box when Making Ext. Memory Data

„ Upload Screen Data and Recipe

„ Open Ext. Memory Data

„ Upload Recipe

„ Update Firmware

14 About ScrEdit

„ Password Protect

„ Print Preview

„ Print

„ File Quick Access

„ Print Setup

„ Exit

20 Most recent used files

„ Edit

Menu Bar and Toolbar Edit

„ Undo

„ Redo

„ Paste

„ Copy

„ Delete

„ Select All

„ Replace

Find

Word

Replace

Replace „ Group

„ Order

„ Ungroup

„ Align

„ Make Same Size

„ Duplicate

„ Text Process

8 Duplicate Example

Menu Bar and Toolbar View

„ View

„ Standard Toolbar

„ Text Format Toolbar

„ Status Bar

„ Element Toolbar

„ Bitmap Toolbar

Revision Apr th, 2007, 2007PDD23000002

„ Build / Layout Toolbar Build Toolbar

„ Zoom Toolbar

3 Property table

„ Zoom

6 Output result of compile operation

„ Zoom Out

9 Zoom level = 300% After Choosing Zoom In command

„ Full Screen

„ Actual Size

„ I/O Screen

„ Grid Setup

15 Show Gird screen

„ Element

Menu Bar and Toolbar Element

4 Right-click the mouse to select the element

„ Create an Element

Revision Apr th, 2007, 2007PDD23000002

„ Move an Element

7 Release left mouse button to create an element

„ Modify Element Height

„ Modify Element Width

„ Input Characters

„ Modify Element Width and Height Simultaneously

13 Right-click the mouse on Toolbar Toolbars window

„ Right-click the Mouse

16 Cross Reference Table dialog box

„ Cross Reference Table

17 Element Part List dialog box

„ Element Part List

Menu Bar and Toolbar Screen

„ Screen

„ New Screen

„ Screen Management

„ Open Screen

4 Screen Management dialog box

„ Cut Screen

6 Warning message after screen is cut

„ Paste Screen

„ Copy Screen

„ Delete Screen

„ Export

„ Screen Open Macro

„ Clear Import Data

„ Screen Close Macro

„ Screen Cycle Macro

11 Auxiliary Keys on HMI panel

„ Auxiliary Key

13 Choosing Screen Properties from docking windows

„ Screen Properties

14 Screen Properties dialog box

17 Sub-screen position

Hard Copy Region option and execute the screen-printing

Menu Bar and Toolbar Tools

Debug Compiling Error during Compiling Process

„ Tools

„ Compile

„ Download Screen & Recipe

4 Start to download the progress will be from 0 to 100%

„ On Line Simulation

„ Download Screen

„ Recipe

„ Off Line Simulation

Recipe Setup

11 Recipe Setup dialog box

Recipe Setup

Recipe Setup

„ 32 bits Floating Recipe

Bits Floating Recipe Setup

Bits Floating Recipe Setup

„ Download Recipe

Recipe Example

„ Control Flag for Reading Recipe

„ Control Flag for Changing Recipe Number

„ Control Flag for Writing Recipe

„ Control Flag for Changing Recipe Group Number

Register for Designating Recipe Number Rbir

27 Control Block Settings of Configuration dialog box

Revision Apr th, 2007, 2007PDD23000002

Revision Apr th, 2007, 2007PDD23000002

Bits Recipe Example

Revision Apr th, 2007, 2007PDD23000002

Revision Apr th, 2007, 2007PDD23000002

Revision Apr th, 2007, 2007PDD23000002

Revision Apr th, 2007, 2007PDD23000002

Revision Apr th, 2007, 2007PDD23000002

Revision Apr th, 2007, 2007PDD23000002

General Recipe Example

Recipe CSV File Editing

Bits Recipe Example

Revision Apr th, 2007, 2007PDD23000002

Standard tab in Configuration option

„ Configuration

Menu Bar and Toolbar Options

„ Options

Standard tab in Configuration option

Communication tab in Configuration option

Communication tab in Configuration option

Print tab in Configuration option

Unchecked Password three options

Default tab in Configuration option

Use Edit Save Screen function in Screen Management

Other tab in Configuration option

HMI

Multi Language Function Example

Revision Apr th, 2007, 2007PDD23000002

101

Revision Apr th, 2007, 2007PDD23000002

Alarm Setup Dialog Box

„ Alarm Setup

According to the user’s requirement

User can click the tab to edit the alarm message contents

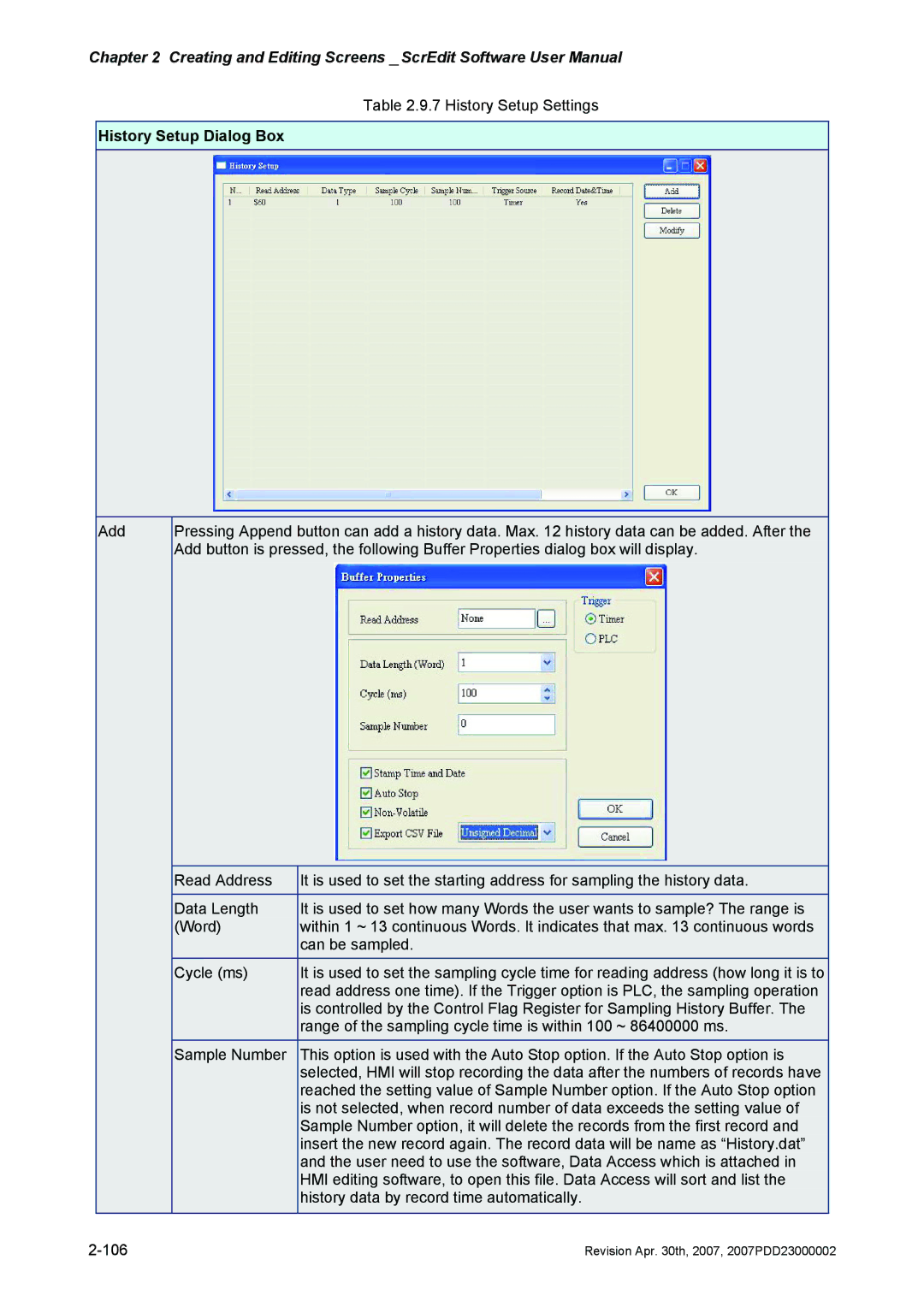

„ History Setup

6Bytesa + 2Bytesb⋅ Nc + 4Bytesd = Actual File Size Bytes

2Bytesa ⋅ Nb = Actual File Size Bytes

History Setup Dialog Box

107

HMI Model USB Flash Drive SM Card

Na ⋅ 240Bytes = Actual File Size MBytes 1024 ⋅

Tag Table Dialog Box

„ Tag Table

Print Function

„ Print Typesetting

111

Create Printing Report

Print Typesetting Function

Print Screen Layout and Output

Revision Apr th, 2007, 2007PDD23000002

Hard Copy Function

Picture Bank Browse Dialog Box

„ Picture Bank

Effect Grayscale Convert the colorful picture to

Text Bank Dialog Box

„ Text Bank

„ Initial Macro

„ Submarro

„ Background Macro

„ Clock Macro

User can choose English, Traditional Chinese

Environment Dialog Box

121

„ Window

Menu Bar and Toolbar Window

„ Close Window

„ Close All Windows

„ Next Window

„ Previous Window

„ Cascade

„ Title Horizontal

10.3 Screen display after choosing Cascade command

„ Window Summary

„ Title Vertical

Menu Bar and Toolbar Help

„ Help

„ About ScrEdit

Element Function

How to Choose Element

2 Choosing Element command from menu bar

Button Type Macro Read Write Function

Button Element

Property Description of General Buttons

„ General Buttons

RCP

Rcpno

Other

Rcpg

Revision Apr th, 2007, 2007PDD23000002

2 Example of Button elements

Property Description of Multistate Buttons

„ Multistate Buttons

Property Description of Set Value Buttons

„ Set Value Button

Word Double Word

„ Set Constant Button

Property Description of Set Constant Buttons

Word/Double Word

Property Description of Increment / Decrement Buttons

„ Increment / Decrement

„ Goto Screen / Previous Page / Previous View Buttons

Revision Apr th, 2007, 2007PDD23000002

5 System function button options 8 System function buttons

„ System Function Button

Property Description of System Function Buttons

SMC

Revision Apr th, 2007, 2007PDD23000002

Property Description of Meter Element

Meter Element

Property Description of Meter Element

Property Description of Normal Bar Element

Bar Element

Property Description of Deviation Bar Element

Property Description of Deviation Bar Element

Property Description of Pipe 1 / Pipe 2 Element

Pipe Element

Property Description of Pipe 4 Element

Property Description of Pipe 3 Element

Property Description of Pipe 6 / Pipe 7 Element

Property Description of Pipe 5 Element

Property Description of Pie Element

Pie Element

Property Description of Pie Element

Property Description of Multistate Indicator Element

Indicator

Property Description of Range Indicator Element

Property Description of Simple Indicator Element

Element Type Function

Data Display

„ Numeric Display

Property Description of Numeric Display Element

User can use y = a x read address value + b this

Property Description of Character Display Element

„ Character Display

Ascii

Property Description of Prestored Message Element

„ Prestored Message

„ Day-of-week Display

Property Description of Day-of-week Display Element

Property Description of Moving Sign Element

Element Type Icon Function

Graph Display

„ Static Graphic

Property Description of Static Graphic Element

Property Description of Static Graphic Element

Property Description of Animated Graphic Element

„ Animated Graphic

Property Description of Dynamic Line Element

„ Dynamic Line

Property Description of Dynamic Rectangle Element

„ Dynamic Rectangle

Property Description of Dynamic Ellipse Element

„ Dynamic Ellipse

Dynamic Line

Dynamic Rectangle

Input Display

„ Numeric Entry

Property Description of Numeric Entry Element

Word Double Word

User can use y = a x read address value + b this

10.2 TEN-KEY input dialog box

Property Description of Character Entry Element

„ Character Entry

Property Description of Character Entry Element

Curve Element

„ Trend Graph

Property Description of Trend Graph Element

When Sample Number is a constant

„ X-Y Chart

Property Description of X-Y Chart Element

Word

Property Description of X-Y Chart Element

When Sample Number is a variable value

Curve Element Example

Revision Apr th, 2007, 2007PDD23000002

Revision Apr th, 2007, 2007PDD23000002

Sampling Element

History Setup Dialog Box

Property Description of Historical Trend Graph Element

„ Historical Trend Graph

Please note that if the data format is selected as Floating,

Time/Date

Property Description of Historical Data Table Element

„ Historical Data Table

Property Description of Historical Event Table Element

„ Historical Event Table

Sampling Element Example

12.2 History Graph

Alarm Element

„ Alarm History Table

Property Description of Alarm History Table Element

Property Description of Active Alarm List Element

„ Active Alarm List

Property Description of Alarm Frequency Table Element

„ Alarm Frequency Table

Property Description of Alarm Moving Sign Element

„ Alarm Moving Sign

Property Description of Alarm Moving Sign Element

Graphic Element

„ Line

Property Description of Line Graphic Element

Property Description of Rectangle Graphic Element

„ Rectangle

„ Circle

Property Description of Circle Graphic Element

Property Description of Polygon Graphic Element

„ Polygon

Property Description of Arc Graphic Element

„ Arc

Property Description of Text Graphic Element

„ Text

„ Scale

Property Description of Scale Graphic Element

Word/Double Word

Property Description of Table Graphic Element

„ Table

Property Description of Table Graphic Element

Property Description of Keypad 1 / 2 / 3 Element

Keypad Element

Property Description of Keypad 1 / 2 / 3 Element

Example for Keypad Element

This page intentionally left blank

Macro Function

Macro Type

„ OFF Macro

„ on Macro

„ Before Execute Macro

„ After Execute Macro

2 Macro Cycle Delay Time Setting

„ Clock Macro

„ Sub-macro

3 Clock Macro Delay Time Setting

2 Toolbar

Macro Editing

3 Last line of Macro

„ Save As Macro

„ File „ Open Macro

7 Save As Macro

„ Copy One or More Macro Commands

9 Paste one or more macro commands

„ Command

„ Update

„ Previous

„ Next

„ Keypad

Macro Operation

„ Definition

„ Arithmetic Operation

Fadd

Revision Apr th, 2007, 2007PDD23000002

„ Addsumw

Within V3 cannot be equal to 0zero

„ SIN

„ COS

„ TAN

„ SEC

„ COT

„ CSC

„ Logical Operation

„ not

„ Data Transfer

„ Fill

„ Bmov

„ Fmov

„ CHR

„ BIN

„ BCD

$4 = -10 Signed $7 = W2D$4Signed

„ Xchg

„ Swap

„ MAX

„ MIN

„ Fcnv

„ IF…THEN Goto Label …

„ Icnv

„ IF…ELSE…ENDIF

„ IF…THEN Call …

Else

Endif

„ Goto

„ Fcmp

„ Label

„ CALL..RET

For

„ FOR…NEXT

Next

„ END

„ Setb

„ Bit Settings

Equation Setb Set V1 Bit to be on

„ Clrb

„ Getb

„ Invb

V1= Initcom

V1=ADDSUMV2

2 Initcom

„ Initcom

DSR/DTR

CTS/RTS

XON/XOFF

„ Addsum

„ Selectcom

„ Getchars

„ Clearcombuffer

„ Chrchksum

„ PLC

„ Communication Macro Example

SELECTCOM1

„ DTB

= Getlasterror

= Timetick

= Getsystemtime

SETSYSTEMTIMEV1

„ Getlasterror

V1 = Gethistory V2

„ Timetick

Equation SETSYSTEMTIMEV1

„ Setsystemtime

„ Gethistory

Get history data Equation V1 = Gethistory V2, V3, V4, V5

Error Messages

„ Code-10 Goto Error

„ HMI Macro Error Messages

„ Code-13 Data Read Error

„ Code-14 Data Write Error

„ Communication Busy

„ HMI Communication Error Messages

„ Controller CheckSum Error

„ HMI CheckSum Error

„ Incorrect Command

„ CTS Signal Fail

„ Controller Station Number Error

„ Uart Communication Error

„ Other Communication Error

Control Block and Status Block

Control Block

„ Register for Designating Screen Number Snir

„ Control Flag Register CFR

„ Enable / Disable Back Light

„ Enable / Disable Communication

„ Enable / Disable Buzzer

„ Clear Control Flag for Alarm Buffer

„ Curve Control Register Cucr

„ Setting User Level

„ Curve Sampling Control Flag

„ Curve Clear Control Flag

„ Register for Clearing History Buffer Hbcr

„ Control Flag Register for Sampling History Buffer

„ Recipe Control Register Recr

„ Clear Flag of History Buffer

„ Multi-Language Setting Value

„ Register for Designating Recipe Number Rbir

„ System Control Flag Register Scfr

„ Printer Form Feed Flag

„ Printer Flag

„ Clear Status of Alarm Buffer

„ Screen Switch Status

Status Block

„ Status Register for General Control Gcsr

„ User Level Status

„ Clear Status of Alarm Counter

„ Status Register for Screen Number Snsr

„ The last open screen number

„ Curve Clear Status Flag

„ Curve Sampling Status Flag

„ Status Register for Sampling History Buffer Hssr

„ Sampling History Buffer Flag

„ Recipe Status Register Resr

„ Clear History Buffer Flag

„ Change Status of Recipe Number Flag

„ Recipe Read Status Flag

„ Multi-language Status Value

„ Printer Status Flag

„ Printer Form Feed Status Flag

This page intentionally left blank

„ Non-volatile Internal Register R/W $M

„ Internal Register R/W $

„ Indirect Address Register R/W *$

„ Receipt Number Register R/W Rcpno

Absolute Address Access

Group Address Access

Making a button to turn on the VFD-E AC drive

Programming Macro files

Revision Apr th, 2007, 2007PDD23000002

Revision Apr th, 2007, 2007PDD23000002

Write Address type in 10.1. See Fig

Revision Apr th, 2007, 2007PDD23000002

Revision Apr th, 2007, 2007PDD23000002

Revision Apr th, 2007, 2007PDD23000002

Making a Stop Button with Macro’s

Revision Apr th, 2007, 2007PDD23000002

Revision Apr th, 2007, 2007PDD23000002

Specifications

Appendix a Specifications and Installation

Model AS38BSTD-W

Model A80THTD1 AE80THTD AE94BSTD A10TCTD AE10THTD

Model A80THTD1 AE80THTD AE94BSTD A10TCTD AE10THTD

„ DOP-AS38BSTD-W Units mm

Dimensions and Profile

„ DOP-AE57G BCSTD-W Units mm

„ DOP-A80THTD1/DOP-AE80THTD

„ DOP-AE94BSTD

„ DOP-A10TCTD/DOP-AE10THTD

Installation

Panel DOP-A80THTD1, DOP-AE80THTD

This page intentionally left blank

Encryption Mode

Appendix B USB Flash Drive Update Function

Fig. B.2

Fig. B.4

Fig. B.8

Fig. B.10

Data Encryption

Revision Apr th, 2007, 2007PDD23000002

Revision Apr th, 2007, 2007PDD23000002

Upgrade Firmware

Copy screen data from a USB flash drive to HMI

Clear HMI Flash ROM

No Encryption Mode

Fig. B.11

Fig. B.13

This page intentionally left blank

Appendix C Main Menu Operation of HMI System

Date/Time Settings

COM Port Upload and Download

Calibrate Touch Panel

Revision Apr th, 2007, 2007PDD23000002

Bypass Mode

Revision Apr th, 2007, 2007PDD23000002

Screen Parameter Settings

System Parameter Settings

System Parameters

Communication Parameters

File Manager

Run HMI

Revision Apr th, 2007, 2007PDD23000002

This page intentionally left blank