INSTALLATION

Checking Gas Connections (Cont.) Installing Logs

13

INSTALLATION

Continued

Test Pressures Equal To or Less Than 1/2 PSIG (3.5 kPa)

1. | Close equipment shutoff valve (see Figure 17). |

2. | Pressurize supply piping system by either opening propane/LP sup- |

| ply tank valve for propane/LP gas or opening main gas valve lo- |

| cated on or near gas meter for natural gas, or using compressed air. |

3. | Check all joints from gas meter to equipment shutoff valve for |

6.Light heater (see Operating Heater, pages 17 and 19 [manu-

7.Turn off heater (see To Turn Off Gas to Appliance, page 18

natural gas or propane/LP supply to equipment shutoff valve |

for propane/LP (see Figures 18 and 19). Apply noncorrosive |

leak detection fluid to all joints. Bubbles forming show a leak. |

4. Correct all leaks at once. |

Pressure Testing Heater Gas Connections

1. | Open equipment shutoff valve (see Figure 17). |

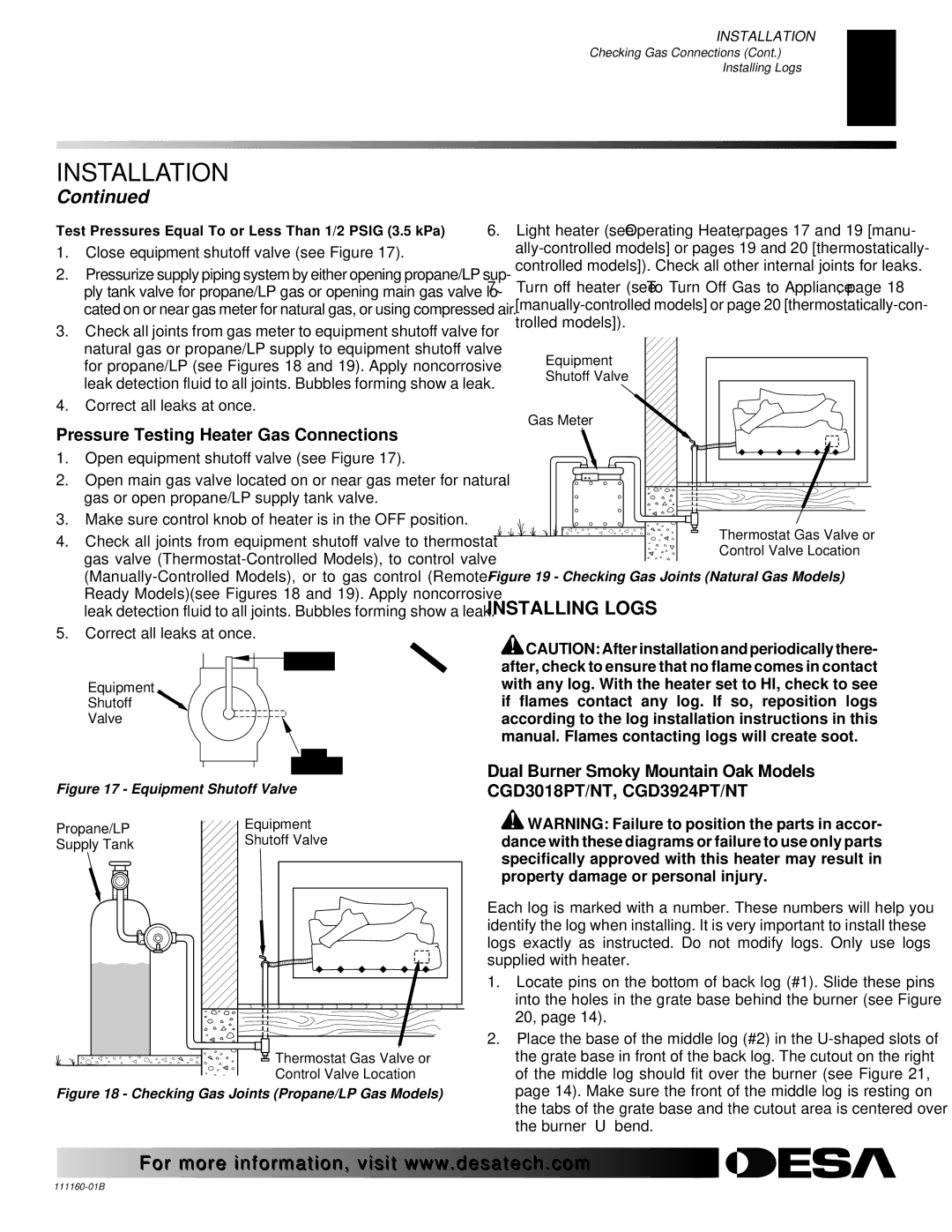

2. | Open main gas valve located on or near gas meter for natural |

| gas or open propane/LP supply tank valve. |

3. | Make sure control knob of heater is in the OFF position. |

4. | Check all joints from equipment shutoff valve to thermostat |

| gas valve |

Equipment Shutoff Valve

Gas Meter

Thermostat Gas Valve or |

Control Valve Location |

Ready Models)(see Figures 18 and 19). Apply noncorrosive |

leak detection fluid to all joints. Bubbles forming show a leak. |

5. Correct all leaks at once. |

Open

Equipment

Shutoff

Valve

Closed

Figure 17 - Equipment Shutoff Valve

Figure 19 - Checking Gas Joints (Natural Gas Models)

INSTALLING LOGS

![]() CAUTION: After installation and periodically there- after, check to ensure that no flame comes in contact with any log. With the heater set to HI, check to see if flames contact any log. If so, reposition logs according to the log installation instructions in this manual. Flames contacting logs will create soot.

CAUTION: After installation and periodically there- after, check to ensure that no flame comes in contact with any log. With the heater set to HI, check to see if flames contact any log. If so, reposition logs according to the log installation instructions in this manual. Flames contacting logs will create soot.

Dual Burner Smoky Mountain Oak Models CGD3018PT/NT, CGD3924PT/NT

Propane/LP Supply Tank

Equipment |

Shutoff Valve |

Thermostat Gas Valve or |

Control Valve Location |

![]() WARNING: Failure to position the parts in accor- dance with these diagrams or failure to use only parts specifically approved with this heater may result in property damage or personal injury.

WARNING: Failure to position the parts in accor- dance with these diagrams or failure to use only parts specifically approved with this heater may result in property damage or personal injury.

Each log is marked with a number. These numbers will help you identify the log when installing. It is very important to install these logs exactly as instructed. Do not modify logs. Only use logs supplied with heater.

1. | Locate pins on the bottom of back log (#1). Slide these pins |

| into the holes in the grate base behind the burner (see Figure |

| 20, page 14). |

2. | Place the base of the middle log (#2) in the |

| the grate base in front of the back log. The cutout on the right |

| of the middle log should fit over the burner (see Figure 21, |

Figure 18 - Checking Gas Joints (Propane/LP Gas Models)

page 14). Make sure the front of the middle log is resting on |

the tabs of the grate base and the cutout area is centered over |

the burner “U” bend. |

For more![]()

![]()

![]() visit www.

visit www.![]()

![]()

![]() .com

.com![]()

![]()

![]()

![]()

![]()