CAST IRON STOVE AND BURNER SYSTEM

VENTING INSTALLATION

Continued

RELINING SYSTEMS

•Suitability and approval of relining ma- terials should be determined.

•Condition, size, height, and termina- tion of the chimney to be relined must be determined.

•No substitution of components should be made.

•Joints and connectors should be made according to manufacturer’s instructions.

NOTICE: Consult the authority having jurisdiction in your area regarding listed chimney liner venting applications.

![]() WARNING: Operation of im- properly installed and maintained venting system could result in serious injury, property damage, or loss of life.

WARNING: Operation of im- properly installed and maintained venting system could result in serious injury, property damage, or loss of life.

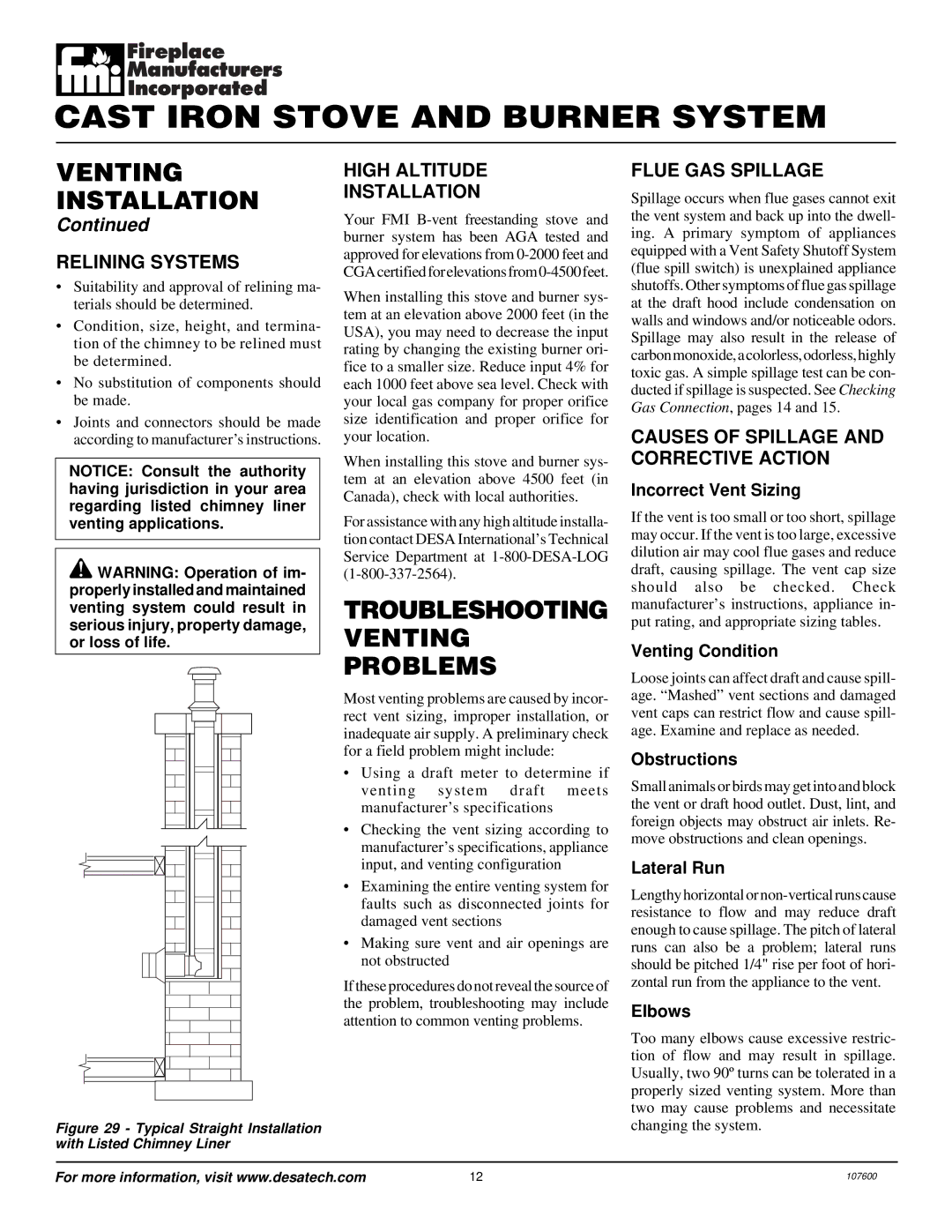

Figure 29 - Typical Straight Installation with Listed Chimney Liner

HIGH ALTITUDE

INSTALLATION

Your FMI

When installing this stove and burner sys- tem at an elevation above 2000 feet (in the USA), you may need to decrease the input rating by changing the existing burner ori- fice to a smaller size. Reduce input 4% for each 1000 feet above sea level. Check with your local gas company for proper orifice size identification and proper orifice for your location.

When installing this stove and burner sys- tem at an elevation above 4500 feet (in Canada), check with local authorities.

For assistance with any high altitude installa- tion contact DESA International’s Technical Service Department at

TROUBLESHOOTING VENTING PROBLEMS

Most venting problems are caused by incor- rect vent sizing, improper installation, or inadequate air supply. A preliminary check for a field problem might include:

•Using a draft meter to determine if venting system draft meets manufacturer’s specifications

•Checking the vent sizing according to manufacturer’s specifications, appliance input, and venting configuration

•Examining the entire venting system for faults such as disconnected joints for damaged vent sections

•Making sure vent and air openings are not obstructed

If these procedures do not reveal the source of the problem, troubleshooting may include attention to common venting problems.

FLUE GAS SPILLAGE

Spillage occurs when flue gases cannot exit the vent system and back up into the dwell- ing. A primary symptom of appliances equipped with a Vent Safety Shutoff System (flue spill switch) is unexplained appliance shutoffs. Other symptoms of flue gas spillage at the draft hood include condensation on walls and windows and/or noticeable odors. Spillage may also result in the release of carbon monoxide, a colorless, odorless, highly toxic gas. A simple spillage test can be con- ducted if spillage is suspected. See Checking Gas Connection, pages 14 and 15.

CAUSES OF SPILLAGE AND CORRECTIVE ACTION

Incorrect Vent Sizing

If the vent is too small or too short, spillage may occur. If the vent is too large, excessive dilution air may cool flue gases and reduce draft, causing spillage. The vent cap size should also be checked. Check manufacturer’s instructions, appliance in- put rating, and appropriate sizing tables.

Venting Condition

Loose joints can affect draft and cause spill- age. “Mashed” vent sections and damaged vent caps can restrict flow and cause spill- age. Examine and replace as needed.

Obstructions

Small animals or birds may get into and block the vent or draft hood outlet. Dust, lint, and foreign objects may obstruct air inlets. Re- move obstructions and clean openings.

Lateral Run

Lengthy horizontal or

Elbows

Too many elbows cause excessive restric- tion of flow and may result in spillage. Usually, two 90º turns can be tolerated in a properly sized venting system. More than two may cause problems and necessitate changing the system.

For more information, visit www.desatech.com | 12 | 107600 |