INSTALLATION

Continued

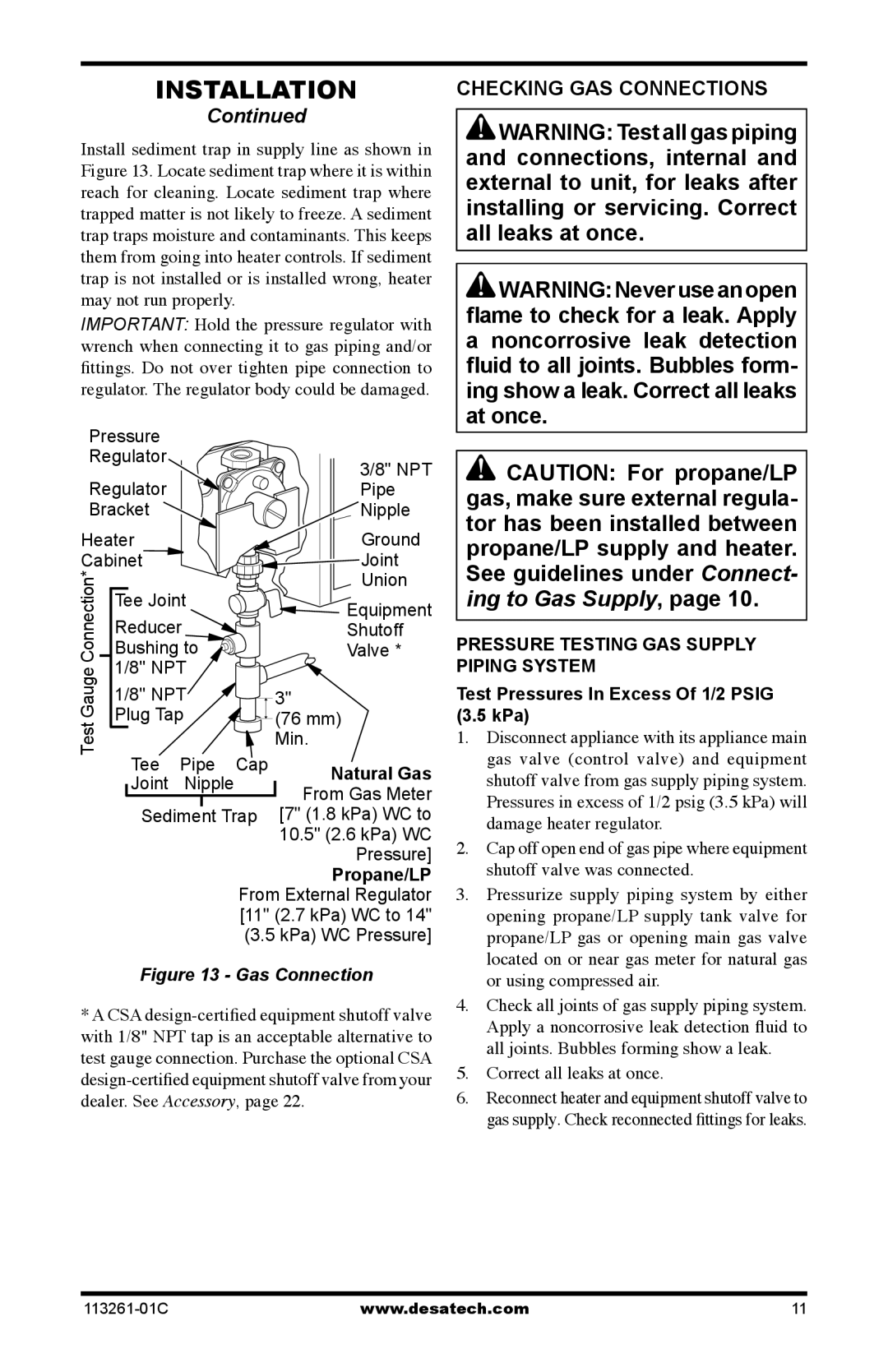

Install sediment trap in supply line as shown in | ||

Figure 13. Locate sediment trap where it is within | ||

reach for cleaning. Locate sediment trap where | ||

trapped matter is not likely to freeze. A sediment | ||

trap traps moisture and contaminants. This keeps | ||

them from going into heater controls. If sediment | ||

trap is not installed or is installed wrong, heater | ||

may not run properly. |

| |

IMPORTANT: Hold the pressure regulator with | ||

wrench when connecting it to gas piping and/or | ||

fittings. Do not over tighten pipe connection to | ||

regulator. The regulator body could be damaged. | ||

Pressure |

| |

Regulator | 3/8" NPT | |

Regulator | ||

Pipe | ||

CHECKING GAS CONNECTIONS

![]() WARNING: Test all gas piping and connections, internal and external to unit, for leaks after installing or servicing. Correct all leaks at once.

WARNING: Test all gas piping and connections, internal and external to unit, for leaks after installing or servicing. Correct all leaks at once.

![]() WARNING:Neveruseanopen flame to check for a leak. Apply a noncorrosive leak detection fluid to all joints. Bubbles form- ing show a leak. Correct all leaks at once.

WARNING:Neveruseanopen flame to check for a leak. Apply a noncorrosive leak detection fluid to all joints. Bubbles form- ing show a leak. Correct all leaks at once.

![]() CAUTION: For propane/LP gas, make sure external regula-

CAUTION: For propane/LP gas, make sure external regula-

Bracket | Nipple |

Heater Cabinet![]()

Connection* | Tee Joint | |

| ||

| Reducer | |

| Bushing to | |

Gauge | 1/8" NPT | |

1/8" NPT | ||

| ||

Test | Plug Tap | |

|

![]() Ground

Ground

![]()

![]() Joint

Joint

Union

![]()

![]() Equipment

Equipment

Shutoff

![]() Valve *

Valve *

3"

![]()

![]()

![]() (76 mm)

(76 mm)

Min.

Natural Gas

From Gas Meter

[7" (1.8 kPa) WC to

10.5" (2.6 kPa) WC

Pressure]

Propane/LP

From External Regulator

[11" (2.7 kPa) WC to 14"

(3.5 kPa) WC Pressure]

Figure 13 - Gas Connection

*A CSA

tor has been installed between propane/LP supply and heater. See guidelines under Connect- ing to Gas Supply, page 10.

PRESSURE TESTING GAS SUPPLY PIPING SYSTEM

Test Pressures In Excess Of 1/2 PSIG (3.5 kPa)

1.Disconnect appliance with its appliance main gas valve (control valve) and equipment shutoff valve from gas supply piping system. Pressures in excess of 1/2 psig (3.5 kPa) will damage heater regulator.

2.Cap off open end of gas pipe where equipment shutoff valve was connected.

3.Pressurize supply piping system by either opening propane/LP supply tank valve for propane/LP gas or opening main gas valve located on or near gas meter for natural gas or using compressed air.

4.Check all joints of gas supply piping system. Apply a noncorrosive leak detection fluid to all joints. Bubbles forming show a leak.

5.Correct all leaks at once.

6.Reconnect heater and equipment shutoff valve to gas supply. Check reconnected fittings for leaks.

www.desatech.com | 11 |