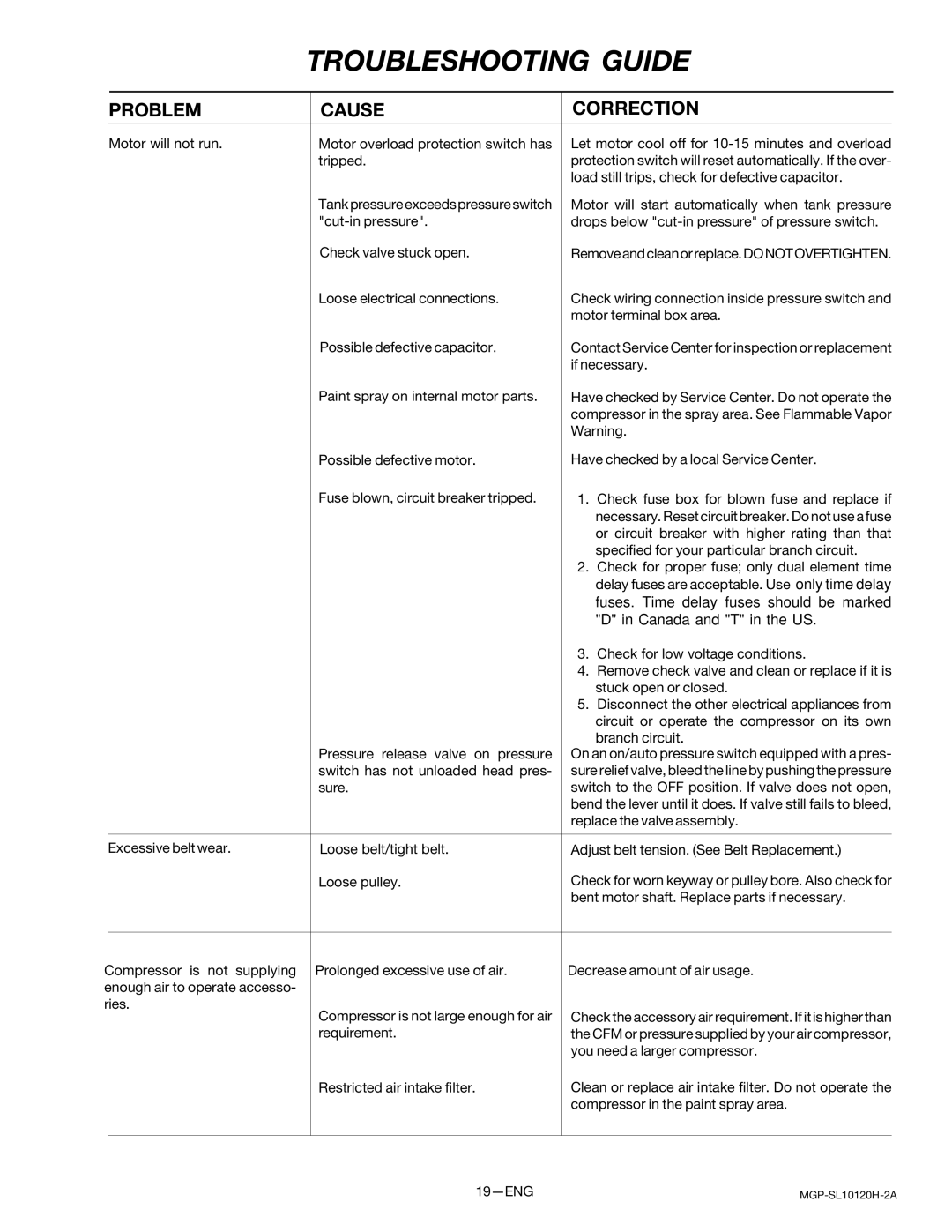

TROUBLESHOOTING GUIDE

|

|

|

|

|

|

| PROBLEM | CAUSE | CORRECTION | ||

|

|

|

|

|

|

| Motor will not run. | Motor overload protection switch has | Let motor cool off for | ||

|

|

| tripped. | protection switch will reset automatically. If the over- | |

|

|

|

| load still trips, check for defective capacitor. | |

|

|

| Tank pressure exceeds pressure switch | Motor will start automatically when tank pressure | |

|

|

| drops below | ||

|

|

| Check valve stuck open. | Removeandcleanorreplace.DONOTOVERTIGHTEN. | |

|

|

| Loose electrical connections. | Check wiring connection inside pressure switch and | |

|

|

|

| motor terminal box area. | |

|

|

| Possible defective capacitor. | Contact Service Center for inspection or replacement | |

|

|

|

| if necessary. | |

|

|

| Paint spray on internal motor parts. | Have checked by Service Center. Do not operate the | |

|

|

|

| compressor in the spray area. See Flammable Vapor | |

|

|

|

| Warning. | |

|

|

| Possible defective motor. | Have checked by a local Service Center. | |

|

|

| Fuse blown, circuit breaker tripped. | 1. Check fuse box for blown fuse and replace if | |

|

|

|

| necessary. Reset circuit breaker. Do not use a fuse | |

|

|

|

| or circuit breaker with higher rating than that | |

|

|

|

| specified for your particular branch circuit. | |

|

|

|

| 2. Check for proper fuse; only dual element time | |

|

|

|

| delay fuses are acceptable. Use only time delay | |

|

|

|

| fuses. Time delay fuses should be marked | |

|

|

|

| "D" in Canada and "T" in the US. | |

|

|

|

| 3. Check for low voltage conditions. | |

|

|

|

| 4. Remove check valve and clean or replace if it is | |

|

|

|

| stuck open or closed. | |

|

|

|

| 5. Disconnect the other electrical appliances from | |

|

|

|

| circuit or operate the compressor on its own | |

|

|

|

| branch circuit. | |

|

|

| Pressure release valve on pressure | On an on/auto pressure switch equipped with a pres- | |

|

|

| switch has not unloaded head pres- | sure relief valve, bleed the line by pushing the pressure | |

|

|

| sure. | switch to the OFF position. If valve does not open, | |

|

|

|

| bend the lever until it does. If valve still fails to bleed, | |

|

|

|

| replace the valve assembly. | |

|

|

|

|

|

|

| Excessive belt wear. | Loose belt/tight belt. | Adjust belt tension. (See Belt Replacement.) | ||

|

|

| Loose pulley. | Check for worn keyway or pulley bore. Also check for | |

|

|

|

| bent motor shaft. Replace parts if necessary. | |

|

|

|

|

|

|

Compressor is not supplying | Prolonged excessive use of air. | Decrease amount of air usage. | |||

enough air to operate accesso- |

|

|

| ||

ries. | Compressor is not large enough for air | Check the accessory air requirement. If it is higher than | |||

|

|

| |||

|

|

| requirement. | the CFM or pressure supplied by your air compressor, | |

|

|

|

| you need a larger compressor. | |

|

|

| Restricted air intake filter. | Clean or replace air intake filter. Do not operate the | |

|

|

|

| compressor in the paint spray area. | |

|

|

|

|

|

|