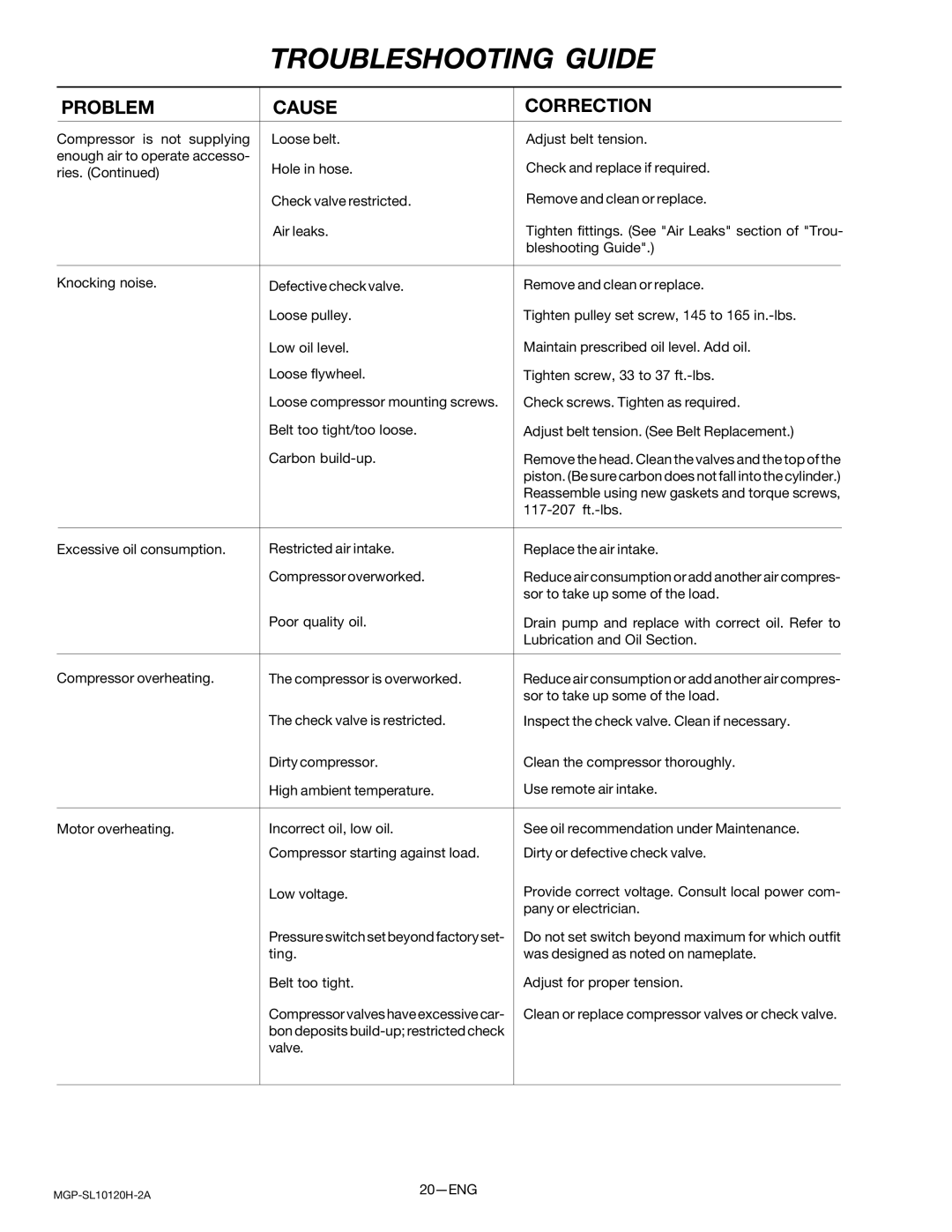

TROUBLESHOOTING GUIDE

PROBLEM | CAUSE | CORRECTION | |

|

|

|

|

Compressor is not supplying | Loose belt. | Adjust belt tension. | |

enough air to operate accesso- | Hole in hose. | Check and replace if required. | |

ries. (Continued) | |||

| Check valve restricted. | Remove and clean or replace. | |

| Air leaks. | Tighten fittings. (See "Air Leaks" section of "Trou- | |

|

| bleshooting Guide".) | |

|

|

|

|

Knocking noise. | Defective check valve. | Remove and clean or replace. | |

| Loose pulley. | Tighten pulley set screw, 145 to 165 | |

| Low oil level. | Maintain prescribed oil level. Add oil. | |

| Loose flywheel. | Tighten screw, 33 to 37 | |

| Loose compressor mounting screws. | Check screws. Tighten as required. | |

| Belt too tight/too loose. | Adjust belt tension. (See Belt Replacement.) | |

| Carbon | Remove the head. Clean the valves and the top of the | |

|

| piston. (Be sure carbon does not fall into the cylinder.) | |

|

| Reassemble using new gaskets and torque screws, | |

|

|

| |

|

|

|

|

Excessive oil consumption. | Restricted air intake. | Replace the air intake. | |

| Compressor overworked. | Reduce air consumption or add another air compres- | |

|

| sor to take up some of the load. | |

| Poor quality oil. | Drain pump and replace with correct oil. Refer to | |

|

| Lubrication and Oil Section. | |

|

|

|

|

Compressor overheating. | The compressor is overworked. | Reduce air consumption or add another air compres- | |

|

| sor to take up some of the load. | |

| The check valve is restricted. | Inspect the check valve. Clean if necessary. | |

| Dirty compressor. | Clean the compressor thoroughly. | |

| High ambient temperature. | Use remote air intake. | |

|

|

|

|

Motor overheating. | Incorrect oil, low oil. | See oil recommendation under Maintenance. | |

| Compressor starting against load. | Dirty or defective check valve. | |

| Low voltage. | Provide correct voltage. Consult local power com- | |

|

| pany or electrician. | |

| Pressure switch set beyond factory set- | Do not set switch beyond maximum for which outfit | |

| ting. | was designed as noted on nameplate. | |

| Belt too tight. | Adjust for proper tension. | |

| Compressor valves have excessive car- | Clean or replace compressor valves or check valve. | |

| bon deposits |

|

|

| valve. |

|

|

|

|

|

|