INSTALLATION AND BREAK-IN PROCEDURES

Location of the Air Compressor | Air Compressor Anchoring |

| Methods |

THE PUMP ASSEMBLY DOES NOT PRO- VIDE ADEQUATE STABILITY OR SUPPORT FOR LIFTING THE UNIT. IF THE OUTFIT MUST BE MOVED, USE THE TANK FOR LIFTING.

This compressor should be permanently mounted in place on a level floor. Operate the air compressor in a clean, dry and well ventilated area. The air intake filter mustbekeptclearofobstructionswhichcouldreduceair delivery of the air compressor. The air compressor should be located at least 12" away from walls or other obstructions that could interfere with the flow of air through the fan bladed flywheel. The air compressor crankcase and head are designed with fins to provide propercooling.

The flywheel side of the outfit should be placed toward the wall and protected with a totally enclosed belt guard. In no case should the flywheel be closer than 12 to 18 inchesfromthewallorotherobstructionthatwillinterfere with the flow of air through the fan bladed flywheel. The area should allow space on all sides for air circulation and for ease of normal maintenance. Keep the outfit awayfromareaswhichhavedirt,vaporandvolatilefumes in the atmosphere which may clog and gum the intake filterandvalves,causinginefficientoperation.Wherethis is not practical a remote air intake is recommended.

Note

Where a remote air intake is used, en- large the size of the air intake piping by one pipe size for each 10 feet of length.

If humidity is high, an air filter can be installed to remove excessive moisture. Closely follow instruc- tions packaged with the filter for proper installation. It must be installed as close as possible to the acces- sory.

The air compressor should be as near to air outlets as possible in order to avoid long pipe lines. Do not place the air compressor where heat is excessive.

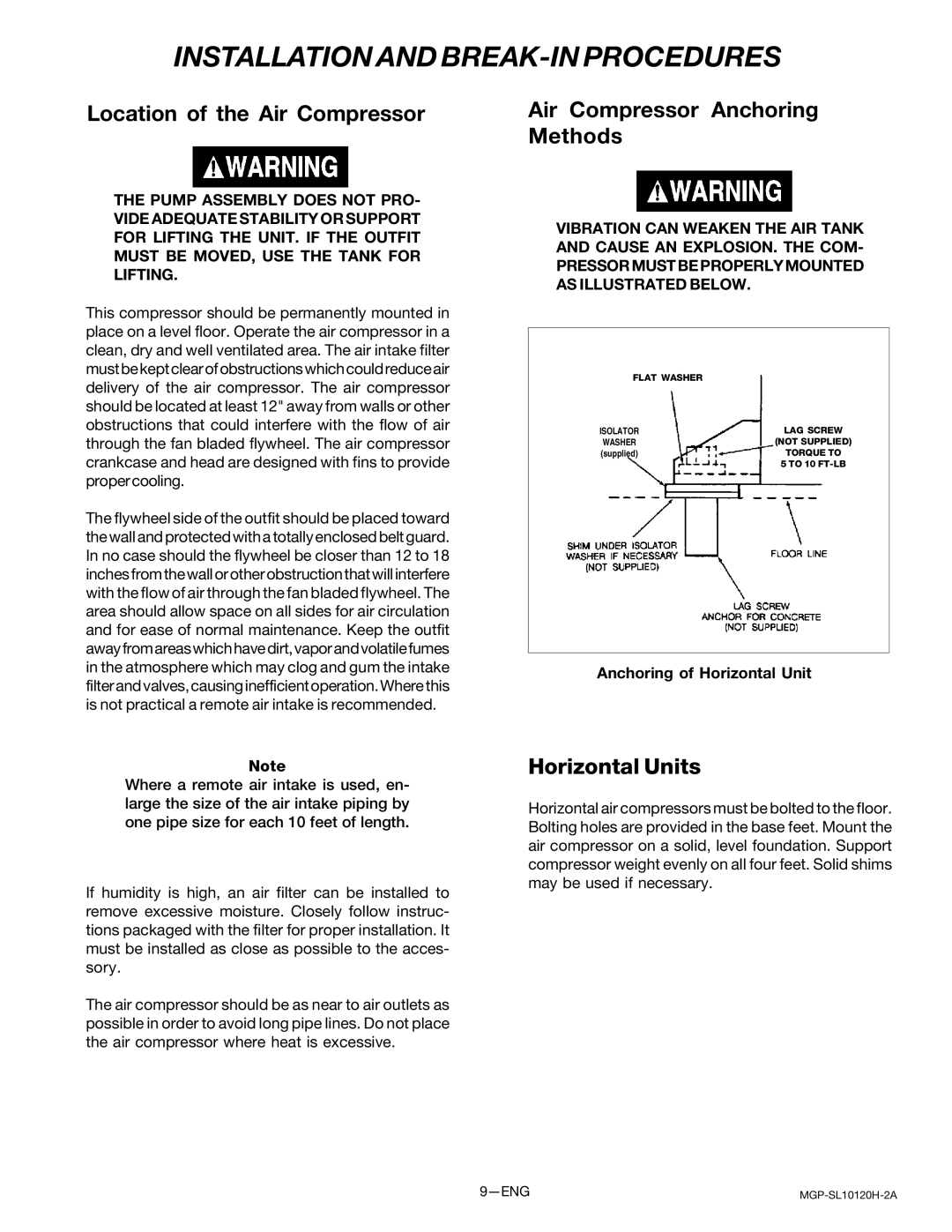

VIBRATION CAN WEAKEN THE AIR TANK AND CAUSE AN EXPLOSION. THE COM- PRESSORMUSTBEPROPERLYMOUNTED AS ILLUSTRATED BELOW.

|

|

|

|

|

|

|

|

|

| FLAT WASHER |

|

| |||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| LAG SCREW |

| ISOLATOR |

|

|

| |||

|

|

|

| (NOT SUPPLIED) | |||

| WASHER |

|

|

| |||

| (supplied) |

|

|

| TORQUE TO | ||

|

|

| |||||

|

|

|

|

|

|

| 5 TO 10 |

|

|

|

|

|

|

|

|

Anchoring of Horizontal Unit

Horizontal Units

Horizontal air compressors must be bolted to the floor. Bolting holes are provided in the base feet. Mount the air compressor on a solid, level foundation. Support compressor weight evenly on all four feet. Solid shims may be used if necessary.