D55273 specifications

The DeWalt D55273 is a robust and highly efficient pneumatic air compressor designed to meet the needs of both professionals and DIY enthusiasts. Renowned for its reliability and performance, this model is particularly popular among contractors involved in framing, roofing, and other heavy-duty applications.One of the standout features of the D55273 is its high-efficiency compressor pump, which delivers an impressive air output while minimizing downtime. The unit boasts a powerful motor that operates at a substantial 4.5 CFM at 90 PSI, allowing it to quickly recharge the tank and maintain consistent pressure for various pneumatic tools. This ensures that users can work continuously without frequent interruptions for recharging.

The D55273 incorporates DeWalt's patented Quiet Technology, making it one of the quieter options in the industry. With a sound level of just 75 dBA, this compressor is ideal for indoor jobs or residential areas where noise levels are a concern. This feature not only enhances user comfort but also reduces the noise pollution that often accompanies pneumatic tools.

Durability is a key characteristic of the D55273. Constructed with high-quality materials, it features a rugged, oil-free pump that requires minimal maintenance and prolongs the life of the compressor. Additionally, the unit is designed with a sturdy frame, making it easy to transport and store without worrying about damage. The integrated handle and rubber grip make it convenient to maneuver on job sites.

Another notable technological advancement in the D55273 is its efficient cooling system. This air compressor is designed with an advanced airflow system that optimizes cooling during operation, reducing the risk of overheating. This capability ensures reliability during extended use, providing peace of mind to users working on demanding projects.

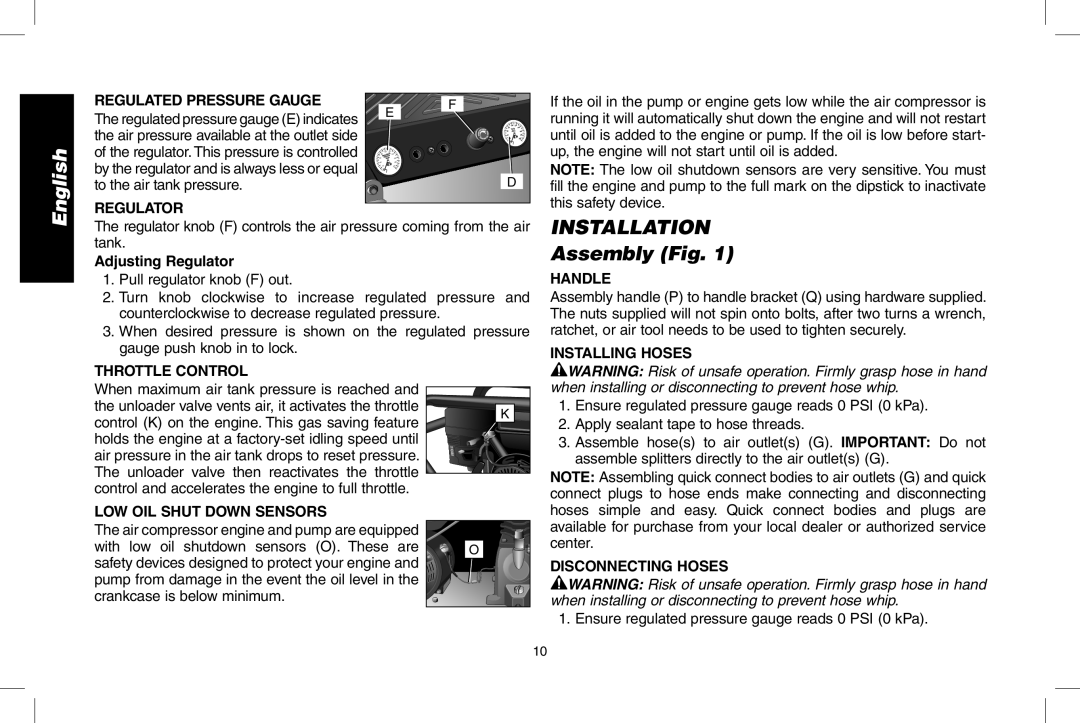

Furthermore, the unit comes equipped with dual quick couplers, allowing for simultaneous connections of two tools, increasing productivity on the job site. The pressure gauges provide accurate readouts, enabling users to easily monitor and adjust the pressure to suit various applications.

Overall, the DeWalt D55273 air compressor combines power, efficiency, and user-friendly features to provide a reliable solution for all pneumatic needs. Whether tackling a large construction project or a small home improvement task, this air compressor delivers the performance and durability professionals demand.