FIG. 8A | YY | FIG. 8B | FF | FIG. 9 |

| EE | |||

|

|

| C | FF |

|

|

| GG | |

|

|

|

| |

|

|

|

| Q |

|

|

|

| Q |

English

4.Lift and slide the riving knife to the approximate position indicated by the markings (non- thru and

5.Tighten the riving knife lock knob.

![]() WARNING: Before connecting the table saw to the power source or operating the saw, always inspect the blade guard assembly and riving knife for proper alignment and clearance with saw blade. Check alignment after each change of bevel angle.

WARNING: Before connecting the table saw to the power source or operating the saw, always inspect the blade guard assembly and riving knife for proper alignment and clearance with saw blade. Check alignment after each change of bevel angle.

NOTE: DO NOT operate saw if riving knife is not locked in the

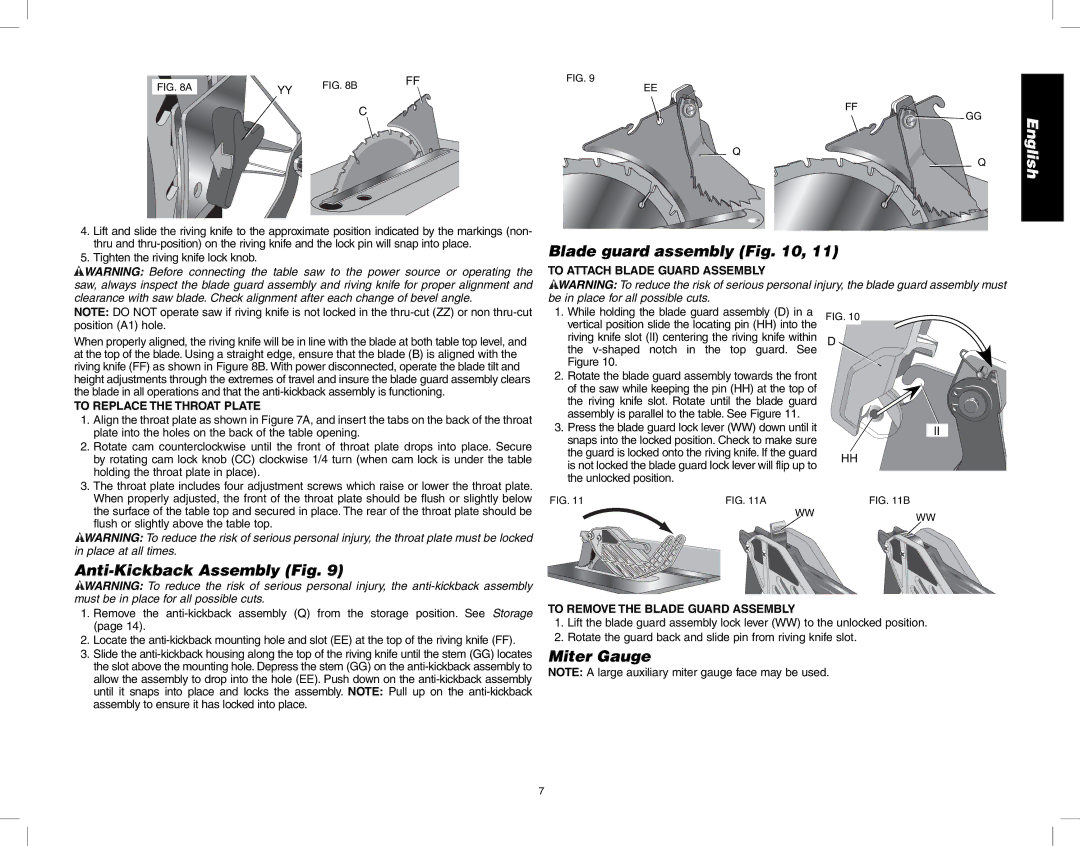

When properly aligned, the riving knife will be in line with the blade at both table top level, and at the top of the blade. Using a straight edge, ensure that the blade (B) is aligned with the riving knife (FF) as shown in Figure 8B. With power disconnected, operate the blade tilt and height adjustments through the extremes of travel and insure the blade guard assembly clears the blade in all operations and that the

TO REPLACE THE THROAT PLATE

1.Align the throat plate as shown in Figure 7A, and insert the tabs on the back of the throat plate into the holes on the back of the table opening.

2.Rotate cam counterclockwise until the front of throat plate drops into place. Secure by rotating cam lock knob (CC) clockwise 1/4 turn (when cam lock is under the table holding the throat plate in place).

3.The throat plate includes four adjustment screws which raise or lower the throat plate. When properly adjusted, the front of the throat plate should be flush or slightly below the surface of the table top and secured in place. The rear of the throat plate should be flush or slightly above the table top.

![]() WARNING: To reduce the risk of serious personal injury, the throat plate must be locked in place at all times.

WARNING: To reduce the risk of serious personal injury, the throat plate must be locked in place at all times.

Anti-Kickback Assembly (Fig. 9)

![]() WARNING: To reduce the risk of serious personal injury, the

WARNING: To reduce the risk of serious personal injury, the

1.Remove the

2.Locate the

3.Slide the

Blade guard assembly (Fig. 10, 11)

TO ATTACH BLADE GUARD ASSEMBLY

![]() WARNING: To reduce the risk of serious personal injury, the blade guard assembly must be in place for all possible cuts.

WARNING: To reduce the risk of serious personal injury, the blade guard assembly must be in place for all possible cuts.

1. While holding the blade guard assembly (D) in a vertical position slide the locating pin (HH) into the riving knife slot (II) centering the riving knife within the

2. Rotate the blade guard assembly towards the front |

| ||||

of the saw while keeping the pin (HH) at the top of |

| ||||

the riving knife slot. Rotate until the blade guard |

| ||||

assembly is parallel to the table. See Figure 11. |

| ||||

3. Press the blade guard lock lever (WW) down until it | II | ||||

snaps into the locked position. Check to make sure | |||||

| |||||

the guard is locked onto the riving knife. If the guard | HH | ||||

is not locked the blade guard lock lever will flip up to | |||||

| |||||

the unlocked position. |

|

| |||

FIG. 11 | FIG. 11A | FIG. 11B | |||

|

|

| WW | WW | |

|

|

|

| ||

|

|

|

|

| |

|

|

|

|

| |

TO REMOVE THE BLADE GUARD ASSEMBLY

1.Lift the blade guard assembly lock lever (WW) to the unlocked position.

2.Rotate the guard back and slide pin from riving knife slot.

Miter Gauge

NOTE: A large auxiliary miter gauge face may be used.

7