Once made, these adjustments should remain accurate. Take a little time now to follow | After confirming that those elements are aligned, proceed with alignment of the blade to the | |||||||

these directions carefully to maintain the accuracy of which your saw is capable. |

| fence using the following procedure: | ||||||

RAIL LOCK ADJUSTMENT |

|

|

|

|

| 1. Unlock the rail lock lever (W) and locate the two fence locator screws (AA) that support | ||

|

|

| FIG. 18 |

| the fence on the front and rear rails. | |||

(Tightening Fence Clamping System) |

|

| ||||||

|

|

| 2. Loosen the rear locator screw and adjust the position of the fence in the groove on the | |||||

1. Lock the rail lock lever (W). |

|

|

|

| ||||

|

|

|

| fence until it sets the fence face parallel to the blade. Make sure you measure from the | ||||

2. On the underside of the saw, loosen the nut (LL) (Fig. 18). |

| |||||||

| fence face to the front and back of the blade to ensure alignment. | |||||||

3. Tighten the hex rod (MM) until the spring on the locking system |

| |||||||

| 3. Tighten the locator screw and repeat on the left side of the blade. | |||||||

is compressed creating the desired tension on the rail lock lever. | MM | |||||||

4. Check rip scale adjustment. | ||||||||

Retighten the jam nut against the hex rod. |

| |||||||

|

| BEVEL STOP AND POINTER ADJUSTMENT | ||||||

4. Flip the saw over and check that the fence does not move when | LL | |||||||

(Calibrating Bevel Scale) | ||||||||

the lock lever is engaged. If the fence is still loose, tighten the |

| |||||||

| Calibrating the bevel system on the saw may require two separate steps, one for the bevel | |||||||

spring further. |

|

|

|

|

| |||

RIP SCALE ADJUSTMENT |

|

|

| FIG. 19 |

| scale and another for the bevel pointer. The scale should always be checked first followed | ||

|

|

|

| by adjustments to the red pointer. | ||||

(Calibrating Rip Scale) |

|

|

|

|

| |||

|

|

|

|

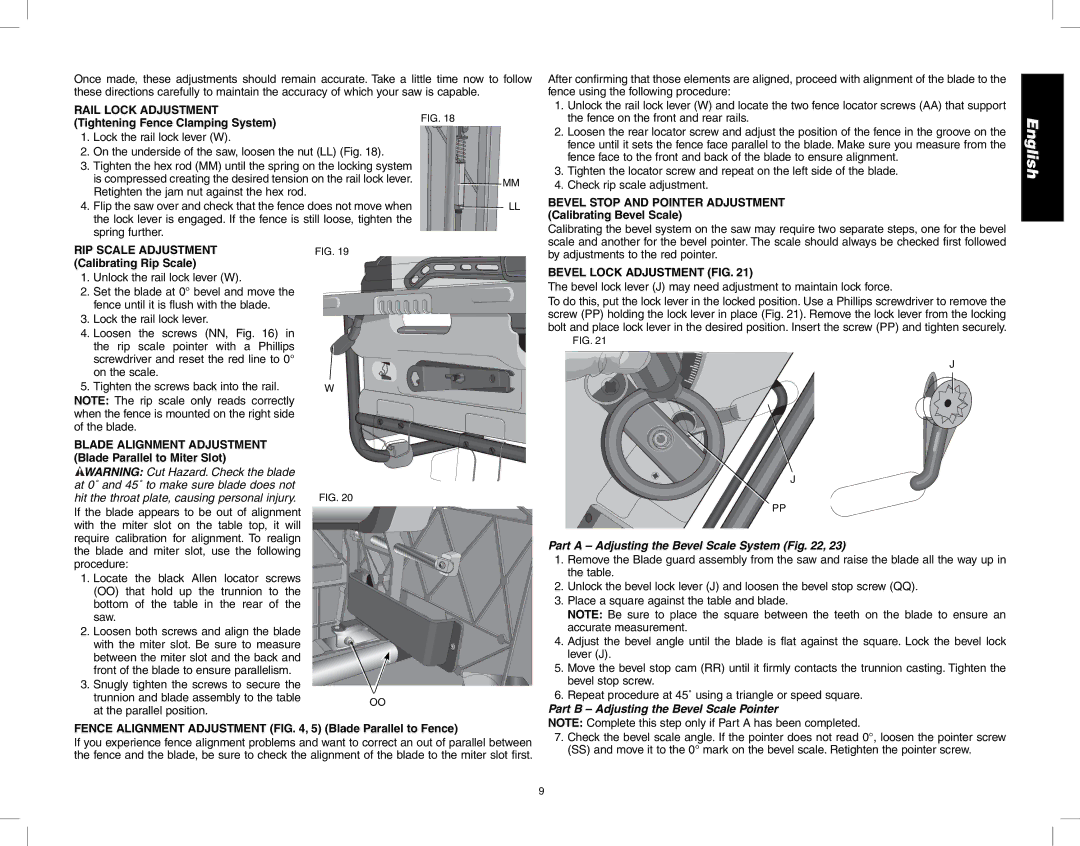

| BEVEL LOCK ADJUSTMENT (FIG. 21) | |||

1. Unlock the rail lock lever (W). |

|

|

|

| ||||

|

|

|

| The bevel lock lever (J) may need adjustment to maintain lock force. | ||||

2. Set the blade at 0° bevel and move the |

|

| ||||||

|

| To do this, put the lock lever in the locked position. Use a Phillips screwdriver to remove the | ||||||

fence until it is flush with the blade. |

|

|

| |||||

|

|

| screw (PP) holding the lock lever in place (Fig. 21). Remove the lock lever from the locking | |||||

3. Lock the rail lock lever. |

|

|

|

|

| |||

|

|

|

|

| bolt and place lock lever in the desired position. Insert the screw (PP) and tighten securely. | |||

4. Loosen the screws (NN, Fig. 16) | in |

|

| |||||

|

| FIG. 21 | ||||||

the rip scale pointer with a Phillips |

|

| ||||||

|

|

| ||||||

screwdriver and reset the red line to 0° |

|

| J | |||||

on the scale. |

|

|

|

|

| |||

|

|

|

|

|

| |||

5. Tighten the screws back into the rail. |

| W |

|

| ||||

NOTE: The rip scale only reads correctly |

|

|

| |||||

when the fence is mounted on the right side |

|

|

| |||||

of the blade. |

|

|

|

|

|

|

| |

BLADE ALIGNMENT ADJUSTMENT |

|

|

|

| ||||

(Blade Parallel to Miter Slot) |

|

|

|

|

| |||

WARNING: Cut Hazard. Check the blade |

|

| J | |||||

at 0˚ and 45˚ to make sure blade does not |

|

| ||||||

|

|

| ||||||

hit the throat plate, causing personal injury. | FIG. 20 |

| PP | |||||

If the blade appears to be out of alignment |

|

| ||||||

|

|

| ||||||

with the miter slot on the table top, it will |

|

|

| |||||

require calibration for alignment. To | realign |

|

| Part A – Adjusting the Bevel Scale System (Fig. 22, 23) | ||||

the blade and miter slot, use the following |

|

| ||||||

|

| 1. Remove the Blade guard assembly from the saw and raise the blade all the way up in | ||||||

procedure: |

|

|

|

|

|

| ||

|

|

|

|

|

| the table. | ||

1. Locate the | black Allen | locator | screws |

|

| |||

|

| 2. Unlock the bevel lock lever (J) and loosen the bevel stop screw (QQ). | ||||||

(OO) that | hold up the | trunnion | to | the |

|

| ||

|

| 3. Place a square against the table and blade. | ||||||

bottom of the table in the rear of the |

|

| ||||||

|

| NOTE: Be sure to place the square between the teeth on the blade to ensure an | ||||||

saw. |

|

|

|

|

|

| ||

2. Loosen both screws and align the blade |

|

| accurate measurement. | |||||

|

| 4. Adjust the bevel angle until the blade is flat against the square. Lock the bevel lock | ||||||

with the miter slot. Be sure to measure |

|

| ||||||

between the miter slot and the back and |

|

| lever (J). | |||||

front of the blade to ensure parallelism. |

|

| 5. Move the bevel stop cam (RR) until it firmly contacts the trunnion casting. Tighten the | |||||

3. Snugly tighten the screws to secure the |

|

| bevel stop screw. | |||||

|

| 6. Repeat procedure at 45˚ using a triangle or speed square. | ||||||

trunnion and blade assembly to the table | OO |

| ||||||

at the parallel position. |

|

|

|

| Part B – Adjusting the Bevel Scale Pointer | |||

|

|

|

|

| ||||

FENCE ALIGNMENT ADJUSTMENT (FIG. 4, 5) (Blade Parallel to Fence) | NOTE: Complete this step only if Part A has been completed. | |

7. Check the bevel scale angle. If the pointer does not read 0°, loosen the pointer screw | ||

If you experience fence alignment problems and want to correct an out of parallel between | ||

(SS) and move it to the 0° mark on the bevel scale. Retighten the pointer screw. | ||

the fence and the blade, be sure to check the alignment of the blade to the miter slot first. | ||

|

English

9