Heavy Duty Large Angle Grinders

General Power Tool Safety Warnings

Definitions Safety Guidelines

Work Area Safety

Electrical Safety

Use Common

Stay alert

Do not

For your

Service

Safety iNSTRUCTiONS for

ALL Operations

Abrasivej Cuing-OffOperations

Kickback and Related Warnings

Position the cord clear of the spinning accessory. /f you

Regularly clean the power tools air vents. The motors

Safety Warnings Specific for Polishing Operations

Additional Safety Warnings Specific for

Safety Warnings Specific for Sanding

Contactwithwheel,andsparksthatcouldigniteclothing

Brushing Operations

Safety Warnings Specific for Wire

Additional Safety Rules for Grinders

Future USE

Save These iNSTRUCTiONS for

Toughcord TM System

Familiarization

Dust Ejection System

AttacMng

Switch Protection TM

Side Handle Fig

DWE4597, DWE4597N, DWE4599N

Attach M Ents

Wheel Mountin9 Accessories Attachments

FIG3. \

Mounting and Removing Guard

Mounting Guard

Sanding Flap Discs

Grinding Wheels Sanding Discs

Type28hubbedwheel

Wheels

Wire Wheels

Flaring Cup Stones

Operation

Switch Fig

Reduce

When

Spindle Lock Button FIG

Trigger Operation with LOCK-ONFEATURE

Mounting and Removing Hubbed Wheels

Mounting NON-HUBBED Wheels

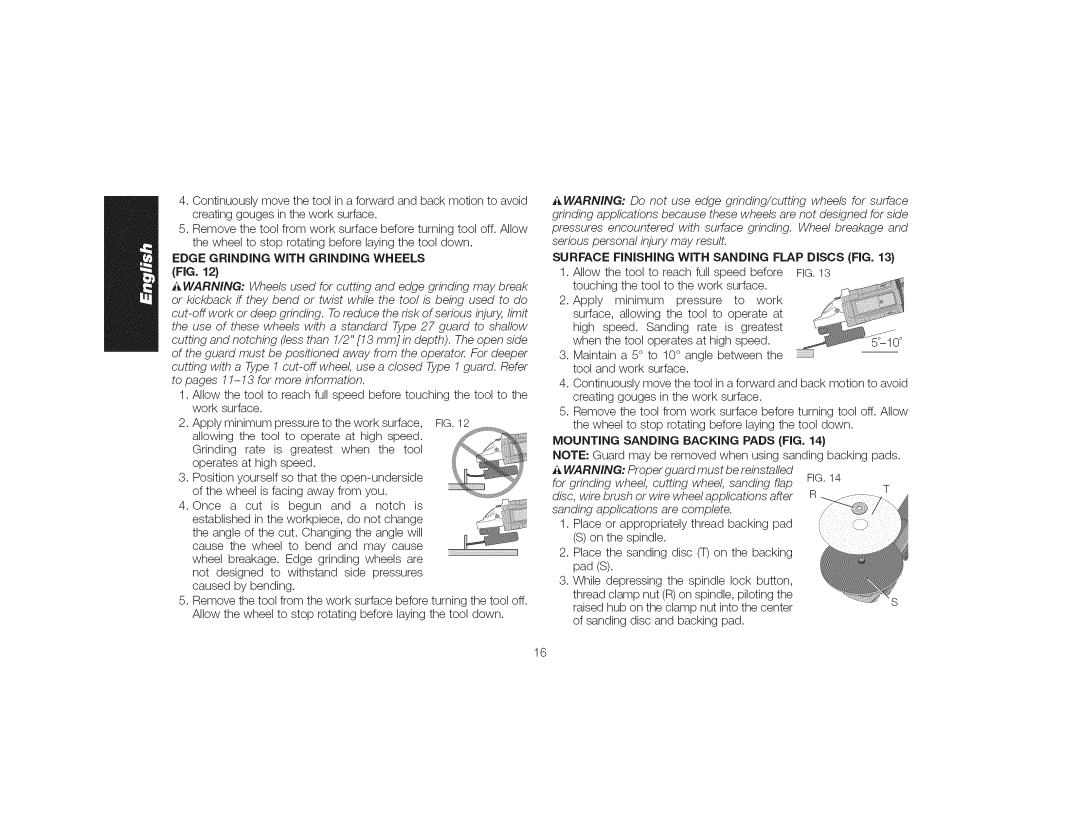

Mounting Sanding Backing Pads FIG

Thewheeltostoprotatingbeforelayingthetooldown

Using Sanding Backing Pads FIG

Precautions To Take When Sanding Paint

Environ M Ental Safety

Sandingdiscwhiledepressingthespindlelockbutton

Cleaning and Disposal

Mounting and Using Wire Brushes and Wire Wheels

Mounting Wire CUP Brushes and Wire Wheels

Dustoutsidetheworkarea

Mounting and Using Flaring Cup

Mounting and Using Cutting Type 1 Wheels

Using a Flaring CUP Wheel FIG

Mounting Flaring CUP Wheel Guard FIG

Mounting Cutting Wheels FIG

Using Cutting Wheels

Thewheeltobendandmaycausewheelbreakage

Maintenance

Repairs

Register Online

DAY Money Back Guarantee

Three Year Limited Warranty

Year Free Service

Aver*issernents de scurit gnraux

Dfinitions Iignes directrices en rnatire de scurit

ET Toutes LES Directives Pour UN Usage Ulterieur

Pour les outils lectriques

Utilisation ET Entretien Dunoutil ¢LECTRIOUE

Nepas exposerlosoutils61ectriques b la pluie ou b

SECURITi Personnelle

#PARATION

BNepas utiliserun outil61ectrique dent Iinterrupteur

Toutes L£S Operations

Page

Rebonds eft avertissernents all, rents

NNepasfairefonctionnerIoutil61ectrique b proximit6 de

Avertissements de scurit spcifiques

Aux operations de rneulage et de coupe Par abrasion

Supplrnentaires spcifiques aux

Avertissernents de scurit

Aux rneuleuses

Rgles additionnelles de scurit propres

Non recommande

ULT E-RIEURE

Conserver CES Consignes Pour

Route

Pendant

POIGN#E Arriere ANTI-VIBRATIONS FIG

Description j 9

Systeme DI#VACUATION DES Poussieres

Carter Automatique

Laterale H peut tre installee sur Iun ou

Installation De la poigne Latrale

Embrayage

=CLUTCH Mc DWE4597, DWE4597N, DWE4599N

SEU LEM ENT

Installation de rneules et daccessoires

Positionnement de la poigne artiste

Dewalt

Disques de pon age , feuillets

¢¢I=SSOI R I=S

D284938po

D284937po D284939po Type27hubbedwheel

Meuleavecmoyeun28

Meules

Meules abrasives

Brosses mdtalliques

Meules boisseaux

Assemblage ET Retrait DU Capot Protecteur

Assemblage du capot protecteur

Utilisation DE Linterrupteur a Gachette

Fonctionnement

Interrupteur Fig

Meulage DE Surface Avec DES Meules FIG

Installation ET Reftrait DES Meules Avec Moyeu

Installation DES Meules Sans Moyeu

Meulagede Chant Avec DES Meules FIG

Toutenenfonantleboutondeverrouillage

LetamponS

La brochetouten tournantle disque

Abrasifjusquce quele disqueet

Nettoyage ET Mise AU Rebut

SECURITiPERSONNELLE

Respect DE Lenvironnement

Brosses Mtalliques a Touret FIG

Utilisation DE Brosses Forme Coupelle ET DE

Montage et utilisation de meules

INSTALLATiON DES Meules

Boisseaux Coniques FIG

Montage DU Capot Protecteur FERM¢ DE Type

Utilisation DE Disques DE Coupe

Pourretirerlecapotprotecteur,degager

Montage DE Disques DE Coupe FIG

Rparations

Accessoires

Neoyage

Garantie lirnite de trois ans

Remplacement Gratuit DES Etiquettes

Contrat Dentretien Gratuit DUN AN

Garantie DE Remboursement DE 90 Jours

Conserve Todas LAS Advebtencias

Definiciones Normas de seguridad

IADVERTENCIA! Lea todas las advertencias de seguridad

Seguridad EN EL Area DE Trabajo

USO Y Mantenimiento DE LA Herramienta Electrica

Seguridad Personal

Mantenimiento

Instrucciones DE Segubidad Paba Todas LAS Opebaciones

Advertencias de seguridad comunes para

Page

Bebote g advertencias relacionadas

Para operaciones de pulido

Advertencias de seguridad especificas

Norrnas de seguridad adicionales para esrneriladoras

Para operaciones de cepillado con cepillo de alarnbre

Largo total

RPM

GUARD£ Estas Instrucciones Para Futuras Consultas

USO Debido

Switch Protection TM Proteccion DE Interruptor Electronico

Mango Trasero Antivibraciones FIG

Sistema DE Extraccion DE Polvo

Fijaci6n

MONTAJ£ Y Ajustes

Mange

=CLUTCH TM

Como girar mango trasero Fig

Rotaci6n de la caja de engranajes Fig

Accesorios y dispositivos para el montaje de los discos

D28499 Solamente

Dispositivos

Sanding Flap Discs

Guardatipo28 D2849389

Guardatipo27 D2849377 D2849399 Discodetipo27

Discotipo28

Discos de lijar

Discos de corse

Ce illos de alambre

Copa de Piedra

Montaje Y Extraccion DEL Protector

Protector de rnontaje

ATENCI6N

Accesorio podria

Encendido Permanente

FUNCIONAMI£NTO

Interrupter Fig

Esmerilado DE Bordes CON Discos DE Esmerilar FIG

Instalacidn DE Discos CON Centro Deprimido

Esmerilado DE Superficie CON Discos DE Esmerilar

Montaje DE LAS Almohadillas DE Respaldo Para Lijar FIG

Acabado DE Superficies CON Discos DE Lijar FIG

Al lijar pintura

Precauciones que debe tenet en cuenta

USO DE Almohadillas DE Respaldo Para Lijar FIG

Seguridad Personal

BeberofumarNosedebendejarartculosparacomer,beber

Discos Alambre

Reducir

Alambre. Pueden

Aplicarlalasuperficiedetrabajo

Permitaquelaherramientaalcancelavelocidadm6,ximaantesde

Sobreunasuperficie

Instalaci6n y utilizaci6n de piedras

SeextiendaApretarfirmementelostornillosdelacamisadelaguarda

Antesdeusarelesmerilador

Montaje y uso de discos de corte

Tipo 1

MANT£NIMi£NTO

Parael di6,metrodelcubodela cajade

Limpieza

Montaje DE LOS Discos DE Corte FIG

Reparaciones

Accesorios

SAN LUlS POTOSI, SLP

P61iza De Garantia

Para Otras Localidades

Identificacion DEL Producto

Garantia DE Reembolso DE SU Dinero POR go Dias

Garantia lirnitada por tres aos

Reemplazo Gratuito DE LAS Etiquetas DE

DWE4557 ,..I,o.ml

DWE4557 DWE4599

Especificaciones

DW4559

DW4579

Capable --CANNOT be Used

Optimal