DYNAFLEX ELASTOMERIC FLEXIBLE COUPLINGS Page 87 of 124

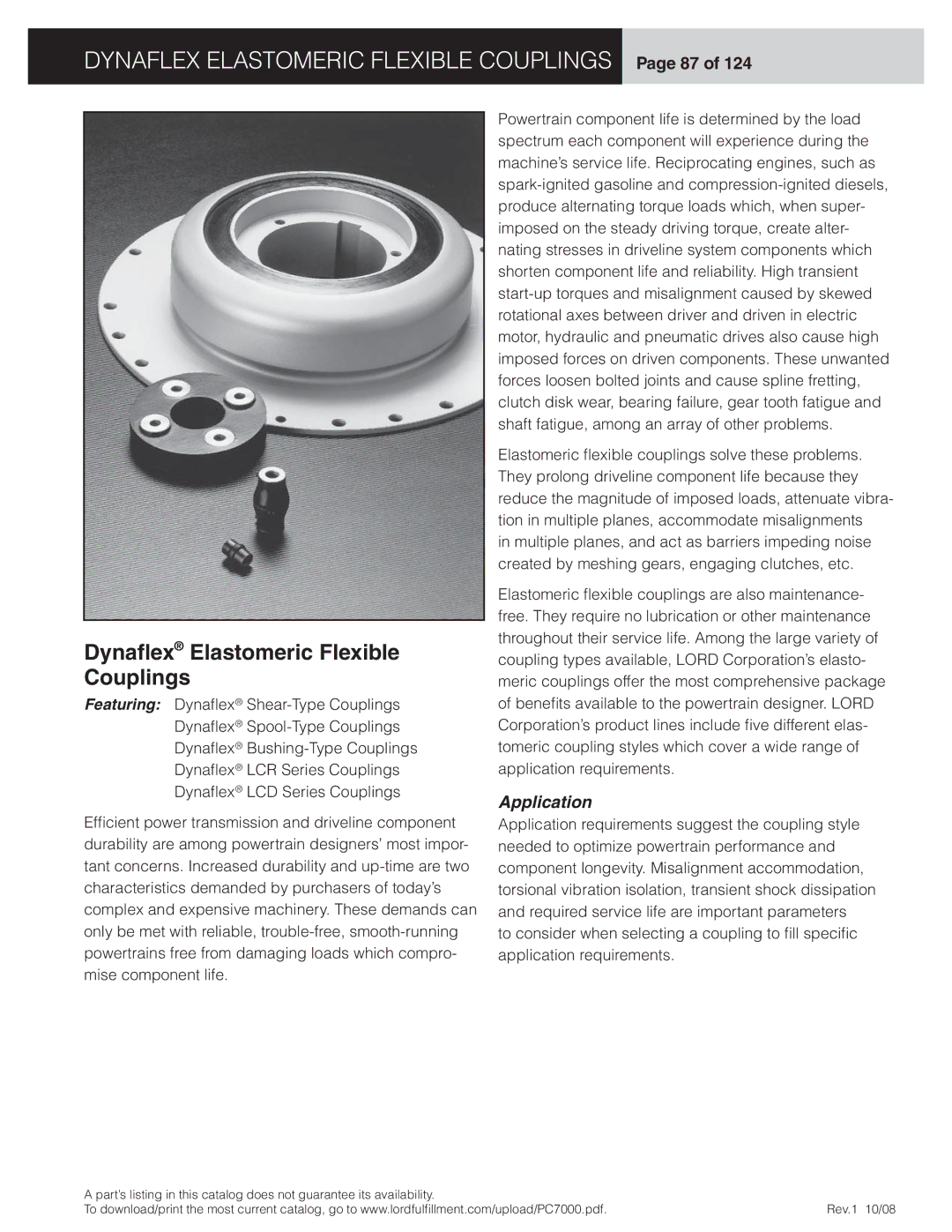

Dynaflex® Elastomeric Flexible Couplings

Featuring: Dynafl ex®

Effi cient power transmission and driveline component durability are among powertrain designers’ most impor- tant concerns. Increased durability and

Powertrain component life is determined by the load spectrum each component will experience during the machine’s service life. Reciprocating engines, such as

Elastomeric fl exible couplings solve these problems. They prolong driveline component life because they reduce the magnitude of imposed loads, attenuate vibra- tion in multiple planes, accommodate misalignments

in multiple planes, and act as barriers impeding noise created by meshing gears, engaging clutches, etc.

Elastomeric fl exible couplings are also maintenance- free. They require no lubrication or other maintenance throughout their service life. Among the large variety of coupling types available, LORD Corporation’s elasto- meric couplings offer the most comprehensive package of benefi ts available to the powertrain designer. LORD Corporation’s product lines include fi ve different elas- tomeric coupling styles which cover a wide range of application requirements.

Application

Application requirements suggest the coupling style needed to optimize powertrain performance and component longevity. Misalignment accommodation, torsional vibration isolation, transient shock dissipation and required service life are important parameters

to consider when selecting a coupling to fi ll specifi c application requirements.

A part’s listing in this catalog does not guarantee its availability. |

|

To download/print the most current catalog, go to www.lordfulfi llment.com/upload/PC7000.pdf. | Rev.1 10/08 |