DYNAFLEX ELASTOMERIC FLEXIBLE COUPLINGS Page 117 of 124

Installation

For engine applications, the outer member is usually bolted directly to the fl ywheel; for other applications, to a suitable adaptor. The inner member normally attaches to the driven shaft. The smaller LCD couplings generally have a tapered bore, which accommodates a standard split tapered bushing which grips the drive shaft. (Refer to Table 1 - Split Tapered Bushings). This confi guration provides easy installation.

Figures 15 and 16 on the next page show typical installations involving universal joints.

Figure 8

Table 5 – Flywheels for Engine Mounted Torque Converters - SAE J927 Nov 88

Converter |

| B |

| C | Tapped Holes | |||

Flywheel |

|

|

|

|

|

|

|

|

in |

| mm | in |

| mm | No. | Size | |

No. |

|

| ||||||

|

|

|

|

|

|

|

|

|

20 | 9.50 |

| 241.30 | 8.750 |

| 222.25 | 12 | |

|

|

|

|

|

|

|

|

|

40 | 10.375 |

| 263.52 | 9.625 |

| 244.48 | 12 | |

|

|

|

|

|

|

|

|

|

60 | 13.875 |

| 352.42 | 13.125 |

| 333.38 | 12 | |

|

|

|

|

|

|

|

|

|

80 | 13.875 |

| 352.42 | 13.125 |

| 333.38 | 12 | |

|

|

|

|

|

|

|

|

|

100 | 13.875 |

| 352.42 | 13.125 |

| 333.38 | 12 | |

|

|

|

|

|

|

|

|

|

120 | 15.500 |

| 393.70 | 14.625 |

| 371.48 | 12 | |

|

|

|

|

|

|

|

|

|

140 | 18.375 |

| 466.72 | 17.250 |

| 438.15 | 12 | |

|

|

|

|

|

|

|

|

|

160 | 20.375 |

| 517.52 | 19.250 |

| 488.95 | 12 | |

|

|

|

|

|

|

|

|

|

180 | 22.500 |

| 571.52 | 21.375 |

| 542.92 | 12 | |

|

|

|

|

|

|

|

|

|

210 | 26.500 |

| 673.10 | 25.250 |

| 641.35 | 12 | |

|

|

|

|

|

|

|

|

|

240 | 28.875 |

| 733.42 | 27.250 |

| 642.15 | 12 | |

|

|

|

|

|

|

|

|

|

This arrangement must not be used. Suitable bearing supports are required to react

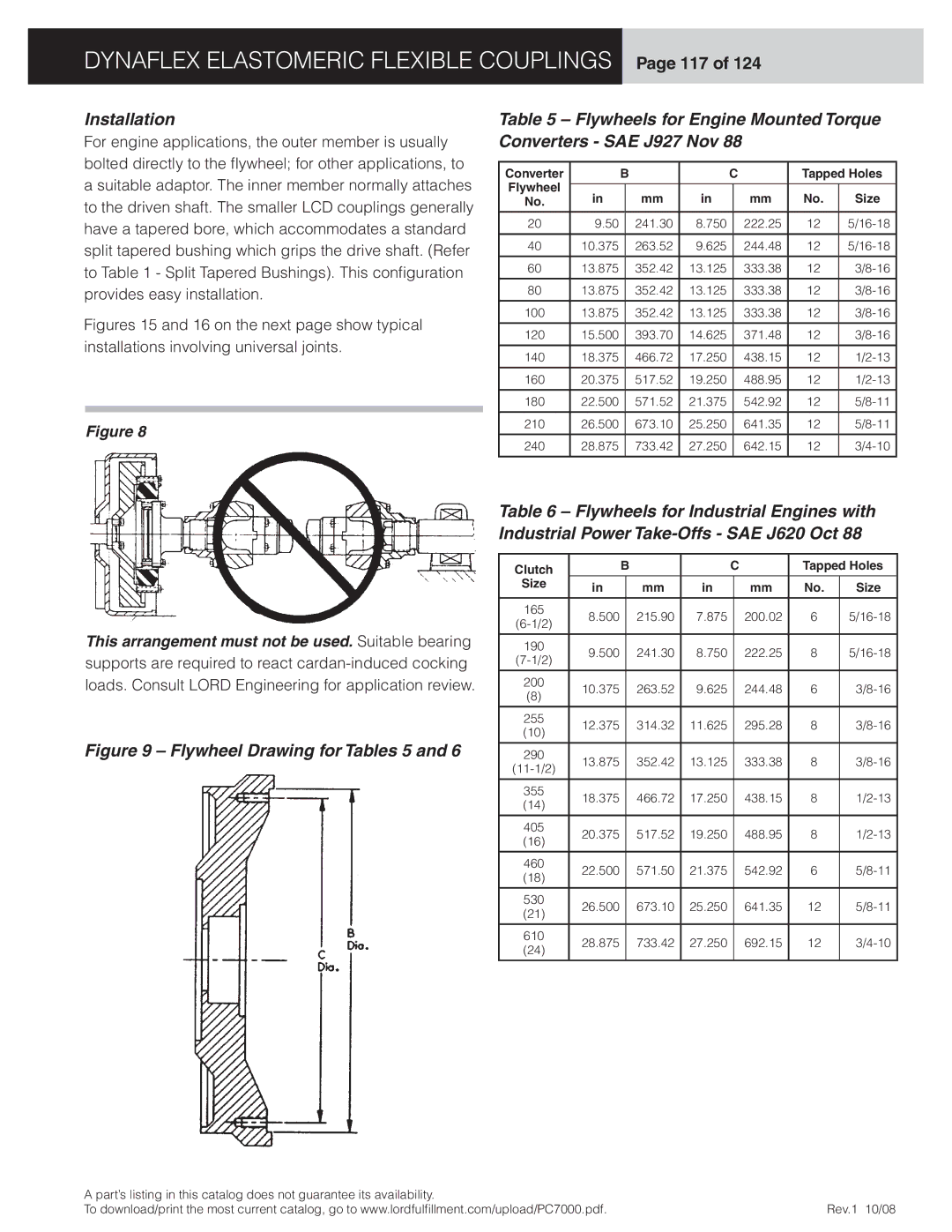

Figure 9 – Flywheel Drawing for Tables 5 and 6

Table 6 – Flywheels for Industrial Engines with Industrial Power Take-Offs - SAE J620 Oct 88

Clutch |

| B |

| C | Tapped Holes | |||

|

|

|

|

|

|

|

| |

Size | in |

| mm | in |

| mm | No. | Size |

|

|

| ||||||

|

|

|

|

|

|

|

|

|

165 | 8.500 |

| 215.90 | 7.875 |

| 200.02 | 6 | |

|

| |||||||

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

190 | 9.500 |

| 241.30 | 8.750 |

| 222.25 | 8 | |

|

| |||||||

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

200 | 10.375 |

| 263.52 | 9.625 |

| 244.48 | 6 | |

(8) |

|

| ||||||

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

255 | 12.375 |

| 314.32 | 11.625 |

| 295.28 | 8 | |

(10) |

|

| ||||||

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

290 | 13.875 |

| 352.42 | 13.125 |

| 333.38 | 8 | |

|

| |||||||

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

355 | 18.375 |

| 466.72 | 17.250 |

| 438.15 | 8 | |

(14) |

|

| ||||||

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

405 | 20.375 |

| 517.52 | 19.250 |

| 488.95 | 8 | |

(16) |

|

| ||||||

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

460 | 22.500 |

| 571.50 | 21.375 |

| 542.92 | 6 | |

(18) |

|

| ||||||

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

530 | 26.500 |

| 673.10 | 25.250 |

| 641.35 | 12 | |

(21) |

|

| ||||||

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

610 | 28.875 |

| 733.42 | 27.250 |

| 692.15 | 12 | |

(24) |

|

| ||||||

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

A part’s listing in this catalog does not guarantee its availability. |

|

To download/print the most current catalog, go to www.lordfulfi llment.com/upload/PC7000.pdf. | Rev.1 10/08 |