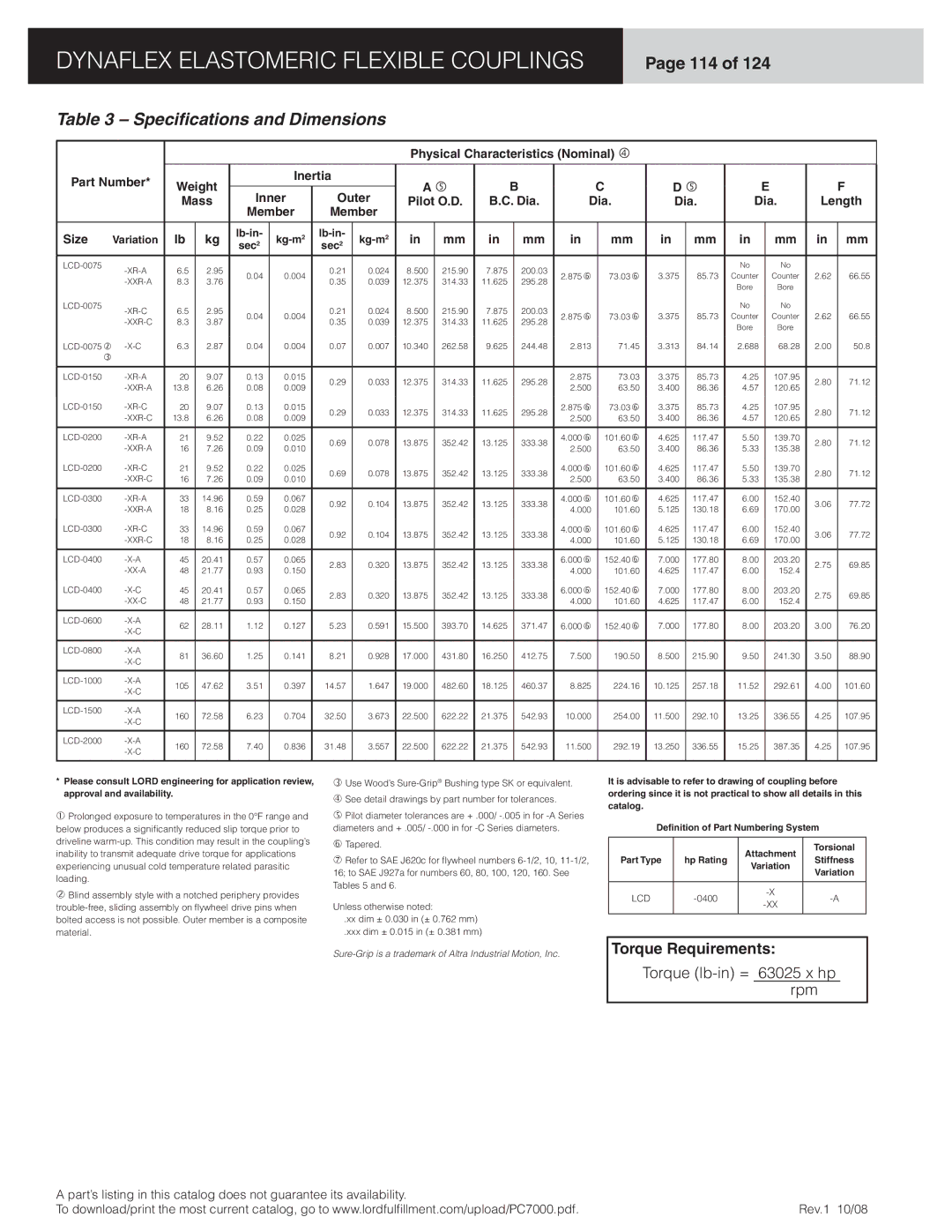

DYNAFLEX ELASTOMERIC FLEXIBLE COUPLINGS | Page 114 of 124 |

|

|

Table 3 – Specifications and Dimensions

|

|

|

|

|

|

|

| Physical Characteristics (Nominal) |

|

|

|

|

|

|

| |||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Part Number* | Weight |

| Inertia |

| A |

|

| B |

| C | D |

|

| E |

| F | ||||||

|

|

|

|

|

|

|

|

|

| |||||||||||||

|

| Inner | Outer |

|

|

|

|

|

| |||||||||||||

|

| Mass | Pilot O.D. | B.C. Dia. | Dia. | Dia. | Dia. | Length | ||||||||||||||

|

|

|

| Member | Member |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||

Size | Variation | lb | kg |

|

| in | mm | in |

| mm | in |

| mm | in | mm | in |

| mm | in | mm | ||

sec2 | sec2 |

|

|

| ||||||||||||||||||

6.5 | 2.95 |

|

| 0.21 | 0.024 | 8.500 | 215.90 | 7.875 |

| 200.03 |

|

|

|

|

| No |

| No |

|

| ||

| 0.04 | 0.004 |

| 2.875 |

| 73.03 | 3.375 | 85.73 | Counter |

| Counter | 2.62 | 66.55 | |||||||||

| 8.3 | 3.76 | 0.35 | 0.039 | 12.375 | 314.33 | 11.625 |

| 295.28 |

|

| |||||||||||

|

|

|

|

|

|

|

|

| Bore |

| Bore |

|

| |||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||

6.5 | 2.95 |

|

| 0.21 | 0.024 | 8.500 | 215.90 | 7.875 |

| 200.03 |

|

|

|

|

| No |

| No |

|

| ||

| 0.04 | 0.004 |

| 2.875 |

| 73.03 | 3.375 | 85.73 | Counter |

| Counter | 2.62 | 66.55 | |||||||||

|

| 8.3 | 3.87 | 0.35 | 0.039 | 12.375 | 314.33 | 11.625 |

| 295.28 |

|

| ||||||||||

|

|

|

|

|

|

|

|

| Bore |

| Bore |

|

| |||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||

6.3 | 2.87 | 0.04 | 0.004 | 0.07 | 0.007 | 10.340 | 262.58 | 9.625 |

| 244.48 | 2.813 |

| 71.45 | 3.313 | 84.14 | 2.688 |

| 68.28 | 2.00 | 50.8 | ||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

20 | 9.07 | 0.13 | 0.015 | 0.29 | 0.033 | 12.375 | 314.33 | 11.625 |

| 295.28 | 2.875 |

| 73.03 | 3.375 | 85.73 | 4.25 |

| 107.95 | 2.80 | 71.12 | ||

| 13.8 | 6.26 | 0.08 | 0.009 |

| 2.500 |

| 63.50 | 3.400 | 86.36 | 4.57 |

| 120.65 | |||||||||

|

|

|

|

|

|

|

|

|

|

|

| |||||||||||

20 | 9.07 | 0.13 | 0.015 | 0.29 | 0.033 | 12.375 | 314.33 | 11.625 |

| 295.28 | 2.875 |

| 73.03 | 3.375 | 85.73 | 4.25 |

| 107.95 | 2.80 | 71.12 | ||

| 13.8 | 6.26 | 0.08 | 0.009 |

| 2.500 |

| 63.50 | 3.400 | 86.36 | 4.57 |

| 120.65 | |||||||||

|

|

|

|

|

|

|

|

|

|

|

| |||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

21 | 9.52 | 0.22 | 0.025 | 0.69 | 0.078 | 13.875 | 352.42 | 13.125 |

| 333.38 | 4.000 |

| 101.60 | 4.625 | 117.47 | 5.50 |

| 139.70 | 2.80 | 71.12 | ||

| 16 | 7.26 | 0.09 | 0.010 |

| 2.500 |

| 63.50 | 3.400 | 86.36 | 5.33 |

| 135.38 | |||||||||

|

|

|

|

|

|

|

|

|

|

|

| |||||||||||

21 | 9.52 | 0.22 | 0.025 | 0.69 | 0.078 | 13.875 | 352.42 | 13.125 |

| 333.38 | 4.000 |

| 101.60 | 4.625 | 117.47 | 5.50 |

| 139.70 | 2.80 | 71.12 | ||

| 16 | 7.26 | 0.09 | 0.010 |

| 2.500 |

| 63.50 | 3.400 | 86.36 | 5.33 |

| 135.38 | |||||||||

|

|

|

|

|

|

|

|

|

|

|

| |||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

33 | 14.96 | 0.59 | 0.067 | 0.92 | 0.104 | 13.875 | 352.42 | 13.125 |

| 333.38 | 4.000 |

| 101.60 | 4.625 | 117.47 | 6.00 |

| 152.40 | 3.06 | 77.72 | ||

| 18 | 8.16 | 0.25 | 0.028 |

| 4.000 |

| 101.60 | 5.125 | 130.18 | 6.69 |

| 170.00 | |||||||||

|

|

|

|

|

|

|

|

|

|

|

| |||||||||||

33 | 14.96 | 0.59 | 0.067 | 0.92 | 0.104 | 13.875 | 352.42 | 13.125 |

| 333.38 | 4.000 |

| 101.60 | 4.625 | 117.47 | 6.00 |

| 152.40 | 3.06 | 77.72 | ||

| 18 | 8.16 | 0.25 | 0.028 |

| 4.000 |

| 101.60 | 5.125 | 130.18 | 6.69 |

| 170.00 | |||||||||

|

|

|

|

|

|

|

|

|

|

|

| |||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

45 | 20.41 | 0.57 | 0.065 | 2.83 | 0.320 | 13.875 | 352.42 | 13.125 |

| 333.38 | 6.000 |

| 152.40 | 7.000 | 177.80 | 8.00 |

| 203.20 | 2.75 | 69.85 | ||

|

| 48 | 21.77 | 0.93 | 0.150 |

| 4.000 |

| 101.60 | 4.625 | 117.47 | 6.00 |

| 152.4 | ||||||||

|

|

|

|

|

|

|

|

|

|

|

| |||||||||||

45 | 20.41 | 0.57 | 0.065 | 2.83 | 0.320 | 13.875 | 352.42 | 13.125 |

| 333.38 | 6.000 |

| 152.40 | 7.000 | 177.80 | 8.00 |

| 203.20 | 2.75 | 69.85 | ||

|

| 48 | 21.77 | 0.93 | 0.150 |

| 4.000 |

| 101.60 | 4.625 | 117.47 | 6.00 |

| 152.4 | ||||||||

|

|

|

|

|

|

|

|

|

|

|

| |||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

62 | 28.11 | 1.12 | 0.127 | 5.23 | 0.591 | 15.500 | 393.70 | 14.625 |

| 371.47 | 6.000 |

| 152.40 | 7.000 | 177.80 | 8.00 |

| 203.20 | 3.00 | 76.20 | ||

|

|

|

| |||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

81 | 36.60 | 1.25 | 0.141 | 8.21 | 0.928 | 17.000 | 431.80 | 16.250 |

| 412.75 | 7.500 |

| 190.50 | 8.500 | 215.90 | 9.50 |

| 241.30 | 3.50 | 88.90 | ||

|

|

|

| |||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

105 | 47.62 | 3.51 | 0.397 | 14.57 | 1.647 | 19.000 | 482.60 | 18.125 |

| 460.37 | 8.825 |

| 224.16 | 10.125 | 257.18 | 11.52 |

| 292.61 | 4.00 | 101.60 | ||

|

|

|

| |||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

160 | 72.58 | 6.23 | 0.704 | 32.50 | 3.673 | 22.500 | 622.22 | 21.375 |

| 542.93 | 10.000 |

| 254.00 | 11.500 | 292.10 | 13.25 |

| 336.55 | 4.25 | 107.95 | ||

|

|

|

| |||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

160 | 72.58 | 7.40 | 0.836 | 31.48 | 3.557 | 22.500 | 622.22 | 21.375 |

| 542.93 | 11.500 |

| 292.19 | 13.250 | 336.55 | 15.25 |

| 387.35 | 4.25 | 107.95 | ||

|

|

|

| |||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

*Please consult LORD engineering for application review, approval and availability.

Prolonged exposure to temperatures in the 0°F range and below produces a signifi cantly reduced slip torque prior to driveline

Blind assembly style with a notched periphery provides

Use Wood’s

See detail drawings by part number for tolerances.

Pilot diameter tolerances are + .000/

Tapered.

Refer to SAE J620c for fl ywheel numbers

Unless otherwise noted:

.xx dim ± 0.030 in (± 0.762 mm)

.xxx dim ± 0.015 in (± 0.381 mm)

It is advisable to refer to drawing of coupling before ordering since it is not practical to show all details in this catalog.

Definition of Part Numbering System

|

| Attachment | Torsional | |

Part Type | hp Rating | Stiffness | ||

Variation | ||||

|

| Variation | ||

|

|

| ||

|

|

|

| |

LCD | ||||

|

|

| ||

|

|

|

|

Torque Requirements:

Torque

A part’s listing in this catalog does not guarantee its availability. |

|

To download/print the most current catalog, go to www.lordfulfi llment.com/upload/PC7000.pdf. | Rev.1 10/08 |