GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 SAFETY CONSIDERATIONS . . . . . . . . . . . . . . . . . . . . . . . 3

REFERENCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

RENEWAL PARTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

AGENCY APPROVALS . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 INSPECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

LIMITATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 LOCATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 RIGGING AND HANDLING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 CLEARANCES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 DUCTWORK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 FIXED OUTDOOR AIR INTAKE DAMPER . . . . . . . . . . . . . . . . . . 6 CONDENSATE DRAIN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 COMPRESSORS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 FILTERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 SERVICE ACCESS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 THERMOSTAT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 POWER AND CONTROL WIRING . . . . . . . . . . . . . . . . . . . . . . . . 7 COMBUSTION DISCHARGE . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 GAS PIPING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 GAS CONNECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 L.P. UNITS, TANKS AND PIPING . . . . . . . . . . . . . . . . . . . . . . . 10 VENT AND COMBUSTION AIR HOODS . . . . . . . . . . . . . . . . . . 11 OPT ECONO/MOTORIZED DAMPER RAIN HOOD . . . . . . . . . 11

ENTHALPY SET POINT ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . 11

PWR EXH/BARO RELIEF DMPR & RAIN HOOD OPT . . . . . . . 11

OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

COOLING SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19 PRELIMINARY OPERATION COOLING . . . . . . . . . . . . . . . . . . 19 COOLING SEQUENCE OF OPERATION . . . . . . . . . . . . . . . . . 19

NO OUTDOOR AIR OPTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19 ECONOMIZER WITH SINGLE ENTHALPY SENSOR . . . . . . . . . . . . . 19 ECONOMIZER WITH DUAL ENTHALPY SENSORS . . . . . . . . . . . . . . 19 ECONOMIZER WITH POWER EXHAUST . . . . . . . . . . . . . . . . . . . . . . 19 MOTORIZED OUTDOOR AIR DAMPERS . . . . . . . . . . . . . . . . . . . . . . 19 CONTINUOUS BLOWER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

SAFETY CONTROLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19 HEATING SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

CONTINUOUS BLOWER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20 INTERMITTENT BLOWER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

SAFETY CONTROLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20 HEAT ANTICIPATOR SETPOINTS . . . . . . . . . . . . . . . . . . . . . . 21

START UP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

PRE-START CHECK LIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21 OPERATING INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . 21

TO LIGHT PILOT AND MAIN BURNERS: . . . . . . . . . . . . . . . . . . . . . . . 21 TO SHUT DOWN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

POST-START CHECK LIST (GAS) . . . . . . . . . . . . . . . . . . . . . . 22 MANIFOLD GAS PRESSURE ADJUSTMENT . . . . . . . . . . . . . . 22 PILOT CHECKOUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22 BURNER INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22 BURNER AIR SHUTTER ADJUSTMENT . . . . . . . . . . . . . . . . . . 23 CHECKING SUPPLY AIR CFM . . . . . . . . . . . . . . . . . . . . . . . . . 23 ADJUSTMENT OF TEMPERATURE RISE . . . . . . . . . . . . . . . . 24

BELT DRIVE BLOWER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

CHECKING GAS INPUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

NATURAL GAS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

SECURE OWNER’S APPROVAL . . . . . . . . . . . . . . . . . . . . . . . . 24

MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

NORMAL MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

FILTERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25 MOTORS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25 OUTDOOR COIL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25 BURNER & PILOT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25 TO CLEAN BURNERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25 COMBUSTION AIR DISCHARGE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

CLEANING FLUE & HEATING ELEMENTS . . . . . . . . . . . . . . . .25

TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

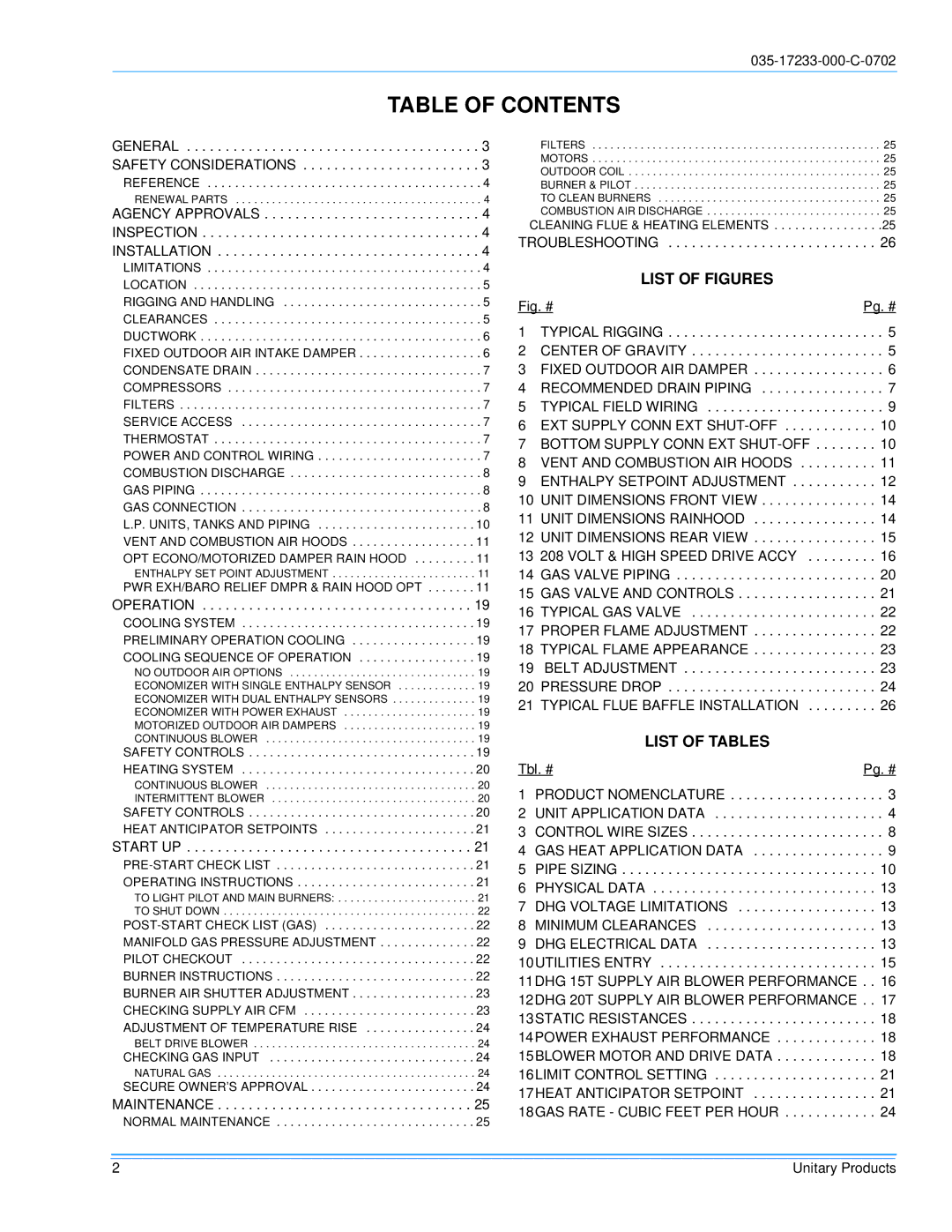

| LIST OF FIGURES | |

Fig. # | Pg. # |

1 | TYPICAL RIGGING | . . . 5 |

2 | CENTER OF GRAVITY | . . . 5 |

3 | FIXED OUTDOOR AIR DAMPER | . . . 6 |

4 | RECOMMENDED DRAIN PIPING | . . . 7 |

5 | TYPICAL FIELD WIRING | . . . 9 |

6 | EXT SUPPLY CONN EXT SHUT-OFF | . . 10 |

7 | BOTTOM SUPPLY CONN EXT SHUT-OFF | . . 10 |

8 | VENT AND COMBUSTION AIR HOODS | . . 11 |

9 | ENTHALPY SETPOINT ADJUSTMENT | . . 12 |

10 | UNIT DIMENSIONS FRONT VIEW | . . 14 |

11 | UNIT DIMENSIONS RAINHOOD | . . 14 |

12 | UNIT DIMENSIONS REAR VIEW | . . 15 |

13 | 208 VOLT & HIGH SPEED DRIVE ACCY | . . 16 |

14 | GAS VALVE PIPING | . . 20 |

15 | GAS VALVE AND CONTROLS | . . 21 |

16 | TYPICAL GAS VALVE | . . 22 |

17 | PROPER FLAME ADJUSTMENT | . . 22 |

18 | TYPICAL FLAME APPEARANCE | . . 23 |

19 | BELT ADJUSTMENT | . . 23 |

20 | PRESSURE DROP | . . 24 |

21 | TYPICAL FLUE BAFFLE INSTALLATION | . . 26 |

| LIST OF TABLES | |

Tbl. # | Pg. # |

1 PRODUCT NOMENCLATURE . . . . . . . . . . . . . . . . . . . . 3 2 UNIT APPLICATION DATA . . . . . . . . . . . . . . . . . . . . . . 4 3 CONTROL WIRE SIZES . . . . . . . . . . . . . . . . . . . . . . . . . 8 4 GAS HEAT APPLICATION DATA . . . . . . . . . . . . . . . . . 9 5 PIPE SIZING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 6 PHYSICAL DATA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13 7 DHG VOLTAGE LIMITATIONS . . . . . . . . . . . . . . . . . . 13 8 MINIMUM CLEARANCES . . . . . . . . . . . . . . . . . . . . . . 13 9 DHG ELECTRICAL DATA . . . . . . . . . . . . . . . . . . . . . . 13 10UTILITIES ENTRY . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15 11DHG 15T SUPPLY AIR BLOWER PERFORMANCE . . 16 12DHG 20T SUPPLY AIR BLOWER PERFORMANCE . . 17 13STATIC RESISTANCES . . . . . . . . . . . . . . . . . . . . . . . . 18 14POWER EXHAUST PERFORMANCE . . . . . . . . . . . . . 18 15BLOWER MOTOR AND DRIVE DATA . . . . . . . . . . . . . 18 16LIMIT CONTROL SETTING . . . . . . . . . . . . . . . . . . . . . 21 17HEAT ANTICIPATOR SETPOINT . . . . . . . . . . . . . . . . 21 18GAS RATE - CUBIC FEET PER HOUR . . . . . . . . . . . . 24