Heat generated within the compressor shell is usually due to:

1.High amperage

2.Low refrigerant charge

3.Frequent recycling

4.Dirty condenser

TERMINAL OVERLOAD - TEST

(Compressor - External Type)

1.Remove overload.

2.Allow time for overload to reset before attempting to test.

3.Apply ohmmeter probes to terminals on overload wires. There should be continuity through the overload.

TERMINAL OVERLOAD (Internal)

Some model compressors are equipped with an internal overload. The overload is embedded in the motor windings to sense the winding temperature and/or current draw. The overload is connected in series with the common motor terminal.

Should the internal temperature and/or current draw become excessive, the contacts in the overload will open, turning off the compressor. The overload will automatically reset, but may require several hours before the heat is dissipated.

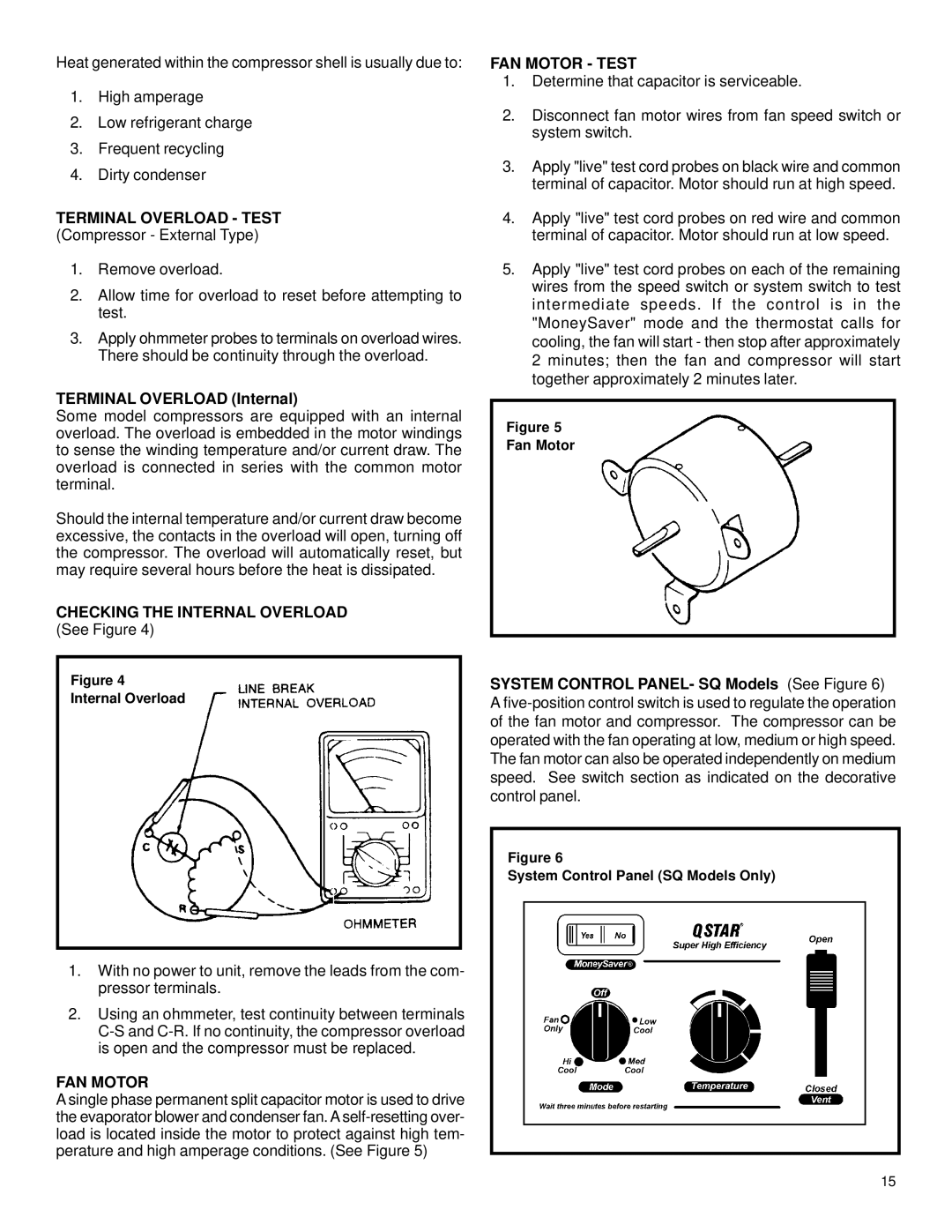

CHECKING THE INTERNAL OVERLOAD

(See Figure 4)

Figure 4

Internal Overload

1.With no power to unit, remove the leads from the com- pressor terminals.

2.Using an ohmmeter, test continuity between terminals

FAN MOTOR

A single phase permanent split capacitor motor is used to drive the evaporator blower and condenser fan. A

FAN MOTOR - TEST

1.Determine that capacitor is serviceable.

2.Disconnect fan motor wires from fan speed switch or system switch.

3.Apply "live" test cord probes on black wire and common terminal of capacitor. Motor should run at high speed.

4.Apply "live" test cord probes on red wire and common terminal of capacitor. Motor should run at low speed.

5.Apply "live" test cord probes on each of the remaining wires from the speed switch or system switch to test intermediate speeds. If the control is in the "MoneySaver" mode and the thermostat calls for cooling, the fan will start - then stop after approximately 2 minutes; then the fan and compressor will start together approximately 2 minutes later.

Figure 5

Fan Motor

SYSTEM CONTROL PANEL- SQ Models (See Figure 6) A

Figure 6

System Control Panel (SQ Models Only)

15