FMCF specifications

The Frymaster FMCF is an innovative frying solution designed to meet the demands of modern commercial kitchens. Known for its advanced technology and efficiency, the FMCF model is a testament to Frymaster's commitment to quality and performance in the foodservice industry. It caters to various frying needs, making it an ideal choice for restaurants, fast-food chains, and catering businesses.One of the main features of the Frymaster FMCF is its high-capacity fry tank, which allows for large volumes of food to be cooked simultaneously. This high-capacity model ensures that busy kitchens can keep up with customer demand without compromising on quality. The unit is designed to accommodate a variety of popular fried items, including chicken, fries, and seafood, making it versatile for diverse menus.

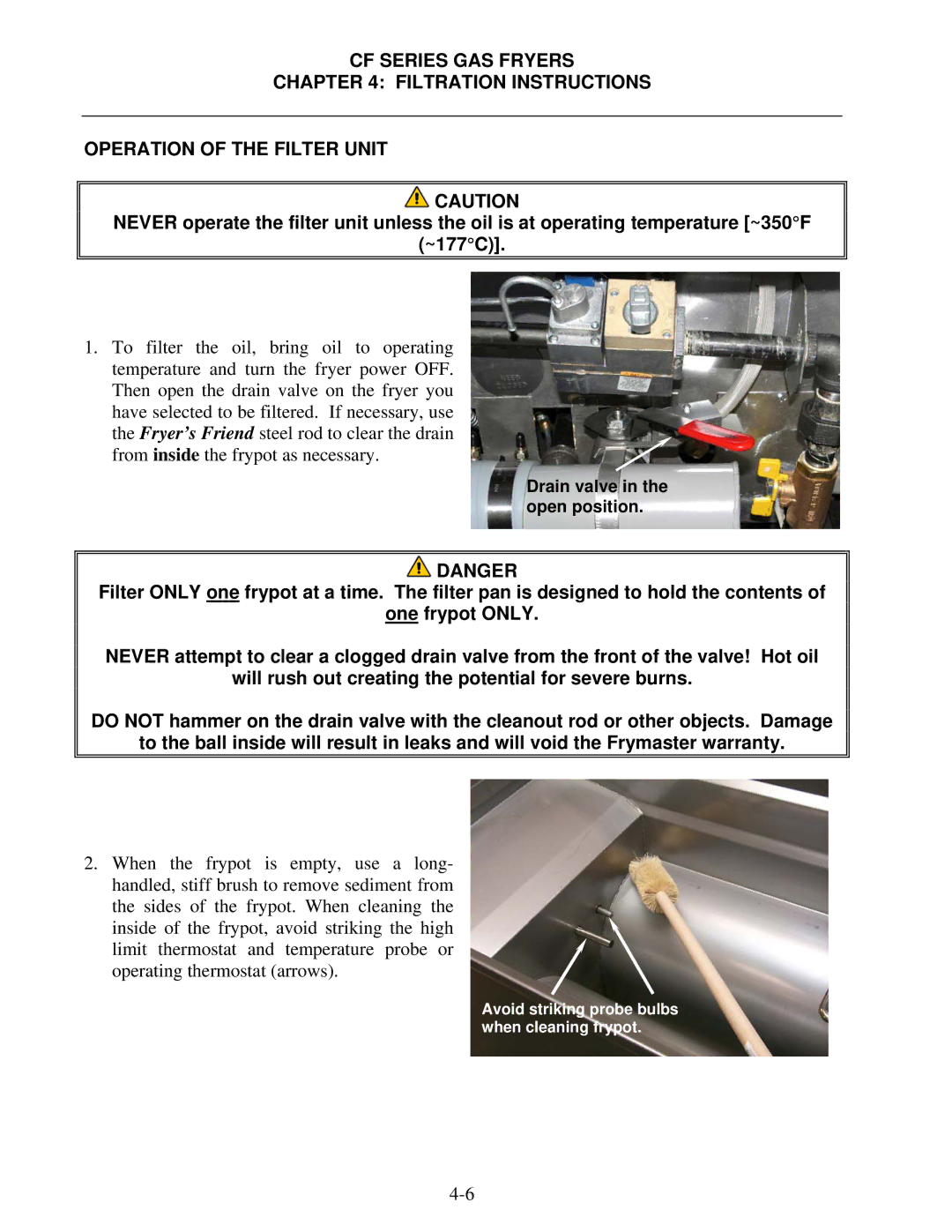

The FMCF incorporates advanced oil filtration technology, which significantly extends the life of the frying oil. This feature not only reduces operational costs but also enhances food quality by maintaining a consistent frying temperature and preventing flavor contamination. The built-in filtration system operates automatically, ensuring that the oil is filtered regularly and efficiently, thus allowing chefs to focus on food preparation rather than maintenance.

Another noteworthy characteristic of the Frymaster FMCF is its user-friendly digital control system. The intuitive interface allows operators to easily monitor and adjust frying times, temperatures, and oil usage. This precision is crucial in achieving perfect frying results consistently. Additionally, the digital controls include programmable cooking profiles, enabling staff to replicate specific cooking processes, which is vital for maintaining product consistency across different shifts and locations.

The Frymaster FMCF is engineered with energy efficiency in mind. Its design minimizes heat loss, resulting in reduced energy consumption. This not only helps save on utility bills but also contributes to a more sustainable operation. This energy efficiency is complemented by safety features, including automatic shut-off valves and temperature controls, which enhance the overall safety of the frying process.

In summary, the Frymaster FMCF is a high-performance fryer that combines capacity, advanced oil filtration, user-friendly controls, and energy efficiency. These features make it a preferred choice for establishments that require reliability, consistency, and quality in their frying operations. With its robust design and innovative technology, the FMCF stands out as an essential tool for modern kitchens looking to deliver the best fried food experiences to their customers.