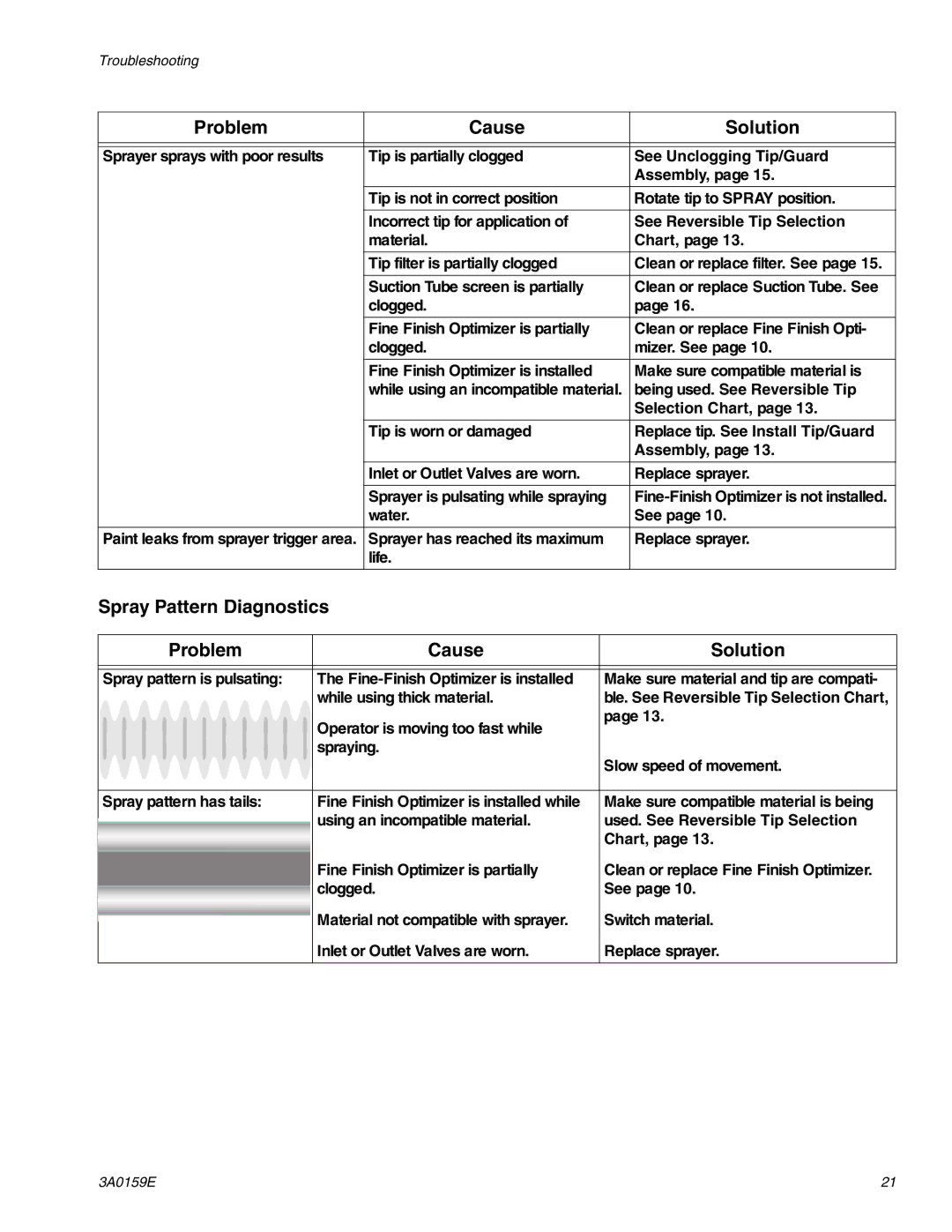

Troubleshooting

Problem | Cause | Solution |

|

|

|

|

|

|

Sprayer sprays with poor results | Tip is partially clogged | See Unclogging Tip/Guard |

|

| Assembly, page 15. |

|

|

|

| Tip is not in correct position | Rotate tip to SPRAY position. |

|

|

|

| Incorrect tip for application of | See Reversible Tip Selection |

| material. | Chart, page 13. |

|

|

|

| Tip filter is partially clogged | Clean or replace filter. See page 15. |

|

|

|

| Suction Tube screen is partially | Clean or replace Suction Tube. See |

| clogged. | page 16. |

|

|

|

| Fine Finish Optimizer is partially | Clean or replace Fine Finish Opti- |

| clogged. | mizer. See page 10. |

|

|

|

| Fine Finish Optimizer is installed | Make sure compatible material is |

| while using an incompatible material. | being used. See Reversible Tip |

|

| Selection Chart, page 13. |

|

|

|

| Tip is worn or damaged | Replace tip. See Install Tip/Guard |

|

| Assembly, page 13. |

|

|

|

| Inlet or Outlet Valves are worn. | Replace sprayer. |

|

|

|

| Sprayer is pulsating while spraying | |

| water. | See page 10. |

|

|

|

Paint leaks from sprayer trigger area. | Sprayer has reached its maximum | Replace sprayer. |

| life. |

|

|

|

|

Spray Pattern Diagnostics |

|

|

Problem | Cause | Solution | |

|

|

|

|

|

|

|

|

Spray pattern is pulsating: | The | Make sure material and tip are compati- | |

|

| while using thick material. | ble. See Reversible Tip Selection Chart, |

|

| Operator is moving too fast while | page 13. |

|

|

| |

|

| spraying. |

|

|

|

| Slow speed of movement. |

|

|

|

|

Spray pattern has tails: | Fine Finish Optimizer is installed while | Make sure compatible material is being | |

|

| using an incompatible material. | used. See Reversible Tip Selection |

|

| ||

|

|

| Chart, page 13. |

|

| Fine Finish Optimizer is partially | Clean or replace Fine Finish Optimizer. |

|

| clogged. | See page 10. |

|

| Material not compatible with sprayer. | Switch material. |

|

| ||

|

| Inlet or Outlet Valves are worn. | Replace sprayer. |

|

|

|

|

3A0159E | 21 |