Setup

Ground System | Fluid Supply Connections |

The equipment must be grounded to reduce the risk of static sparking and electric shock. Electric or static sparking can cause fumes to ignite or explode.

Improper grounding can cause electric shock. Grounding provides an escape wire for the electric current.

•Reactor: is grounded through power cord; see page 16.

•Spray gun: connect whip hose ground wire to FTS; see page 19. Do not disconnect wire or spray with- out whip hose.

•Fluid supply containers: follow your local code.

•Object being sprayed: follow your local code.

•Solvent pails used when flushing: follow your local code. Use only metal pails that are conductive. Place them on a grounded surface. Do no place pail on a nonconductive surface, such as paper or cardboard, which interrupts grounding continuity.

•To maintain grounding continuity when flushing or relieving pressure, hold a metal part of spray gun firmly to the side of a grounded metal pail, then trigger gun.

Iso Pump Lubrication System Setup

Prepare isocyanate pump lubrication system as follows:

1.Lift lubricant reservoir out of bracket and remove reservoir from cap.

2.Fill reservoir 3/4 full with TSL.

3.Thread reservoir onto cap assembly and place it into bracket.

The lubrication system is now ready for operation; no priming is required.

Feed pumps are typically used. Siphon feeding is not recommended. Connect material supply to inlets of proportioning unit as follows:

1.Connect fluid inlet ball valves (U.X) and

2.Ensure the A- and B- inlet ball valves (U,X) on pro- portioning unit are closed.

3.Connect and tighten B- supply hose (J) to 3/4 NPT swivel fitting (GG) on B- inlet ball valve (U), and to resin transfer pump.

GG

J

V

U ti17571a

4.Connect and tighten A- supply hose (BB) to 1/2 NPT swivel fitting (FF) on A- inlet ball valve (X), and to isocyanate transfer pump. See FIG. 3, page 11.

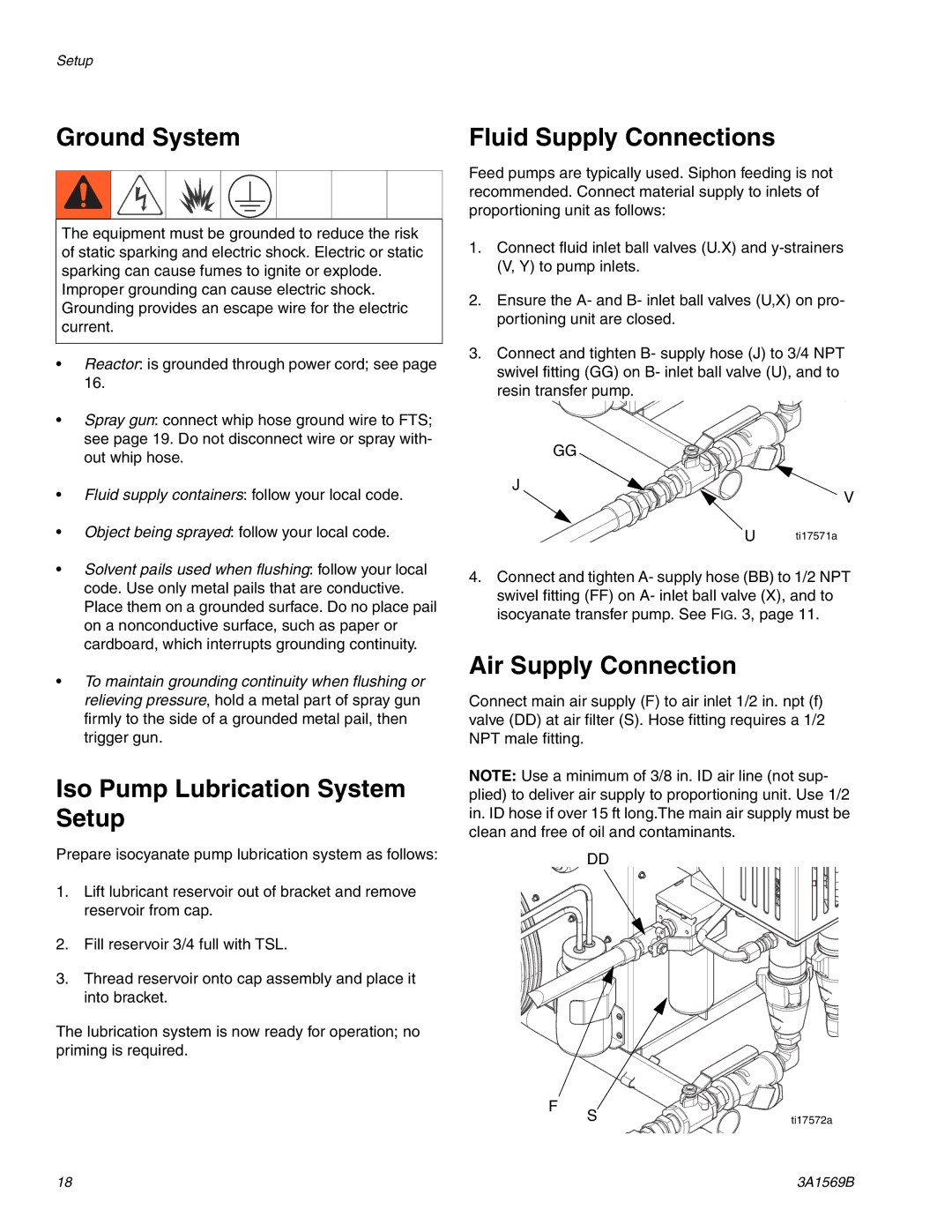

Air Supply Connection

Connect main air supply (F) to air inlet 1/2 in. npt (f) valve (DD) at air filter (S). Hose fitting requires a 1/2 NPT male fitting.

NOTE: Use a minimum of 3/8 in. ID air line (not sup- plied) to deliver air supply to proportioning unit. Use 1/2 in. ID hose if over 15 ft long.The main air supply must be clean and free of oil and contaminants.

DD

F | S | ti17572a |

|

18 | 3A1569B |