Operation

Operation

Daily Start-up Procedure

NOTE: The daily

1.Check condition isocyanate lubrication system and service as required. Change pump lubricant when it shows signs of change to a milky color.

2.Ensure supply fluid is at correct temperature as recommended by chemical system supplier. Ensure individual chemicals are correctly agitated within their drums/day tanks, and moisture protection system is properly set for operation. Recirculate heated fluid back to supply drums if necessary; see page 30.

3.Turn on main air supply to transfer pumps.

4.Pressurize transfer pumps and open A- and

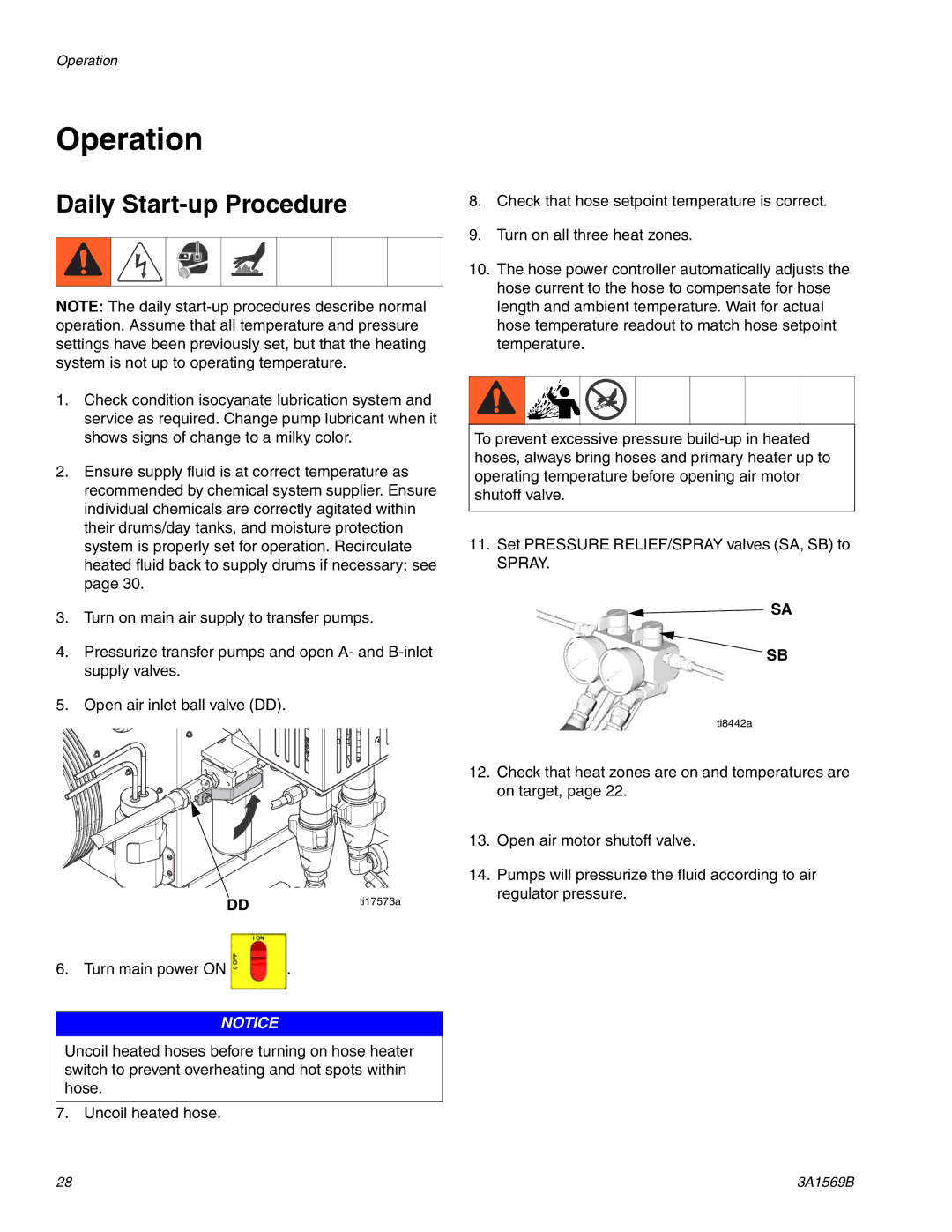

5.Open air inlet ball valve (DD).

DDti17573a

6. Turn main power ON | . |

NOTICE

Uncoil heated hoses before turning on hose heater switch to prevent overheating and hot spots within hose.

7. Uncoil heated hose.

8.Check that hose setpoint temperature is correct.

9.Turn on all three heat zones.

10.The hose power controller automatically adjusts the hose current to the hose to compensate for hose length and ambient temperature. Wait for actual hose temperature readout to match hose setpoint temperature.

To prevent excessive pressure

11.Set PRESSURE RELIEF/SPRAY valves (SA, SB) to

SPRAY.

![]() SA

SA

SB

ti8442a

12.Check that heat zones are on and temperatures are on target, page 22.

13.Open air motor shutoff valve.

14.Pumps will pressurize the fluid according to air regulator pressure.

28 | 3A1569B |