|

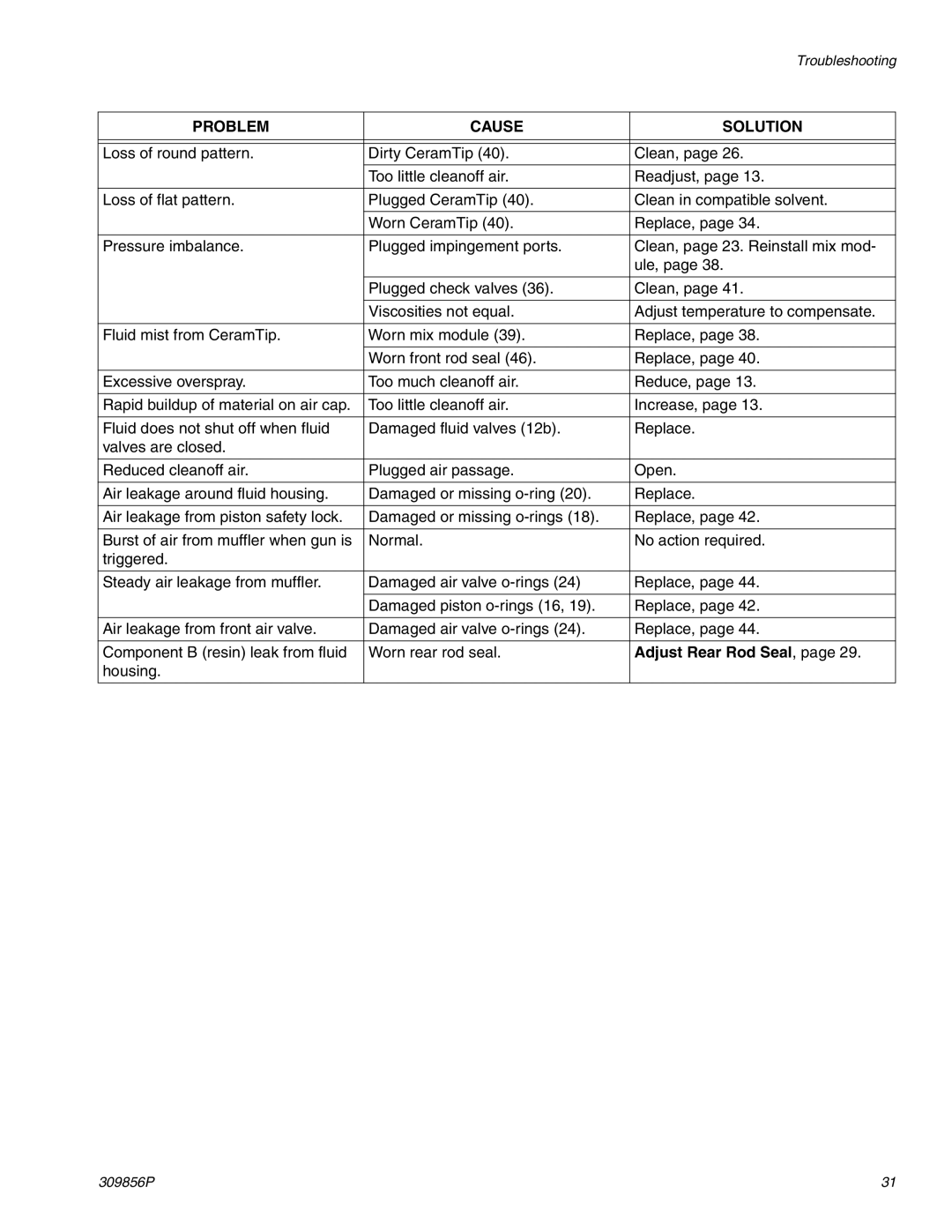

| Troubleshooting |

|

|

|

PROBLEM | CAUSE | SOLUTION |

|

|

|

|

|

|

Loss of round pattern. | Dirty CeramTip (40). | Clean, page 26. |

|

|

|

| Too little cleanoff air. | Readjust, page 13. |

|

|

|

Loss of flat pattern. | Plugged CeramTip (40). | Clean in compatible solvent. |

|

|

|

| Worn CeramTip (40). | Replace, page 34. |

|

|

|

Pressure imbalance. | Plugged impingement ports. | Clean, page 23. Reinstall mix mod- |

|

| ule, page 38. |

|

|

|

| Plugged check valves (36). | Clean, page 41. |

|

|

|

| Viscosities not equal. | Adjust temperature to compensate. |

|

|

|

Fluid mist from CeramTip. | Worn mix module (39). | Replace, page 38. |

|

|

|

| Worn front rod seal (46). | Replace, page 40. |

|

|

|

Excessive overspray. | Too much cleanoff air. | Reduce, page 13. |

|

|

|

Rapid buildup of material on air cap. | Too little cleanoff air. | Increase, page 13. |

|

|

|

Fluid does not shut off when fluid | Damaged fluid valves (12b). | Replace. |

valves are closed. |

|

|

|

|

|

Reduced cleanoff air. | Plugged air passage. | Open. |

|

|

|

Air leakage around fluid housing. | Damaged or missing | Replace. |

|

|

|

Air leakage from piston safety lock. | Damaged or missing | Replace, page 42. |

|

|

|

Burst of air from muffler when gun is | Normal. | No action required. |

triggered. |

|

|

|

|

|

Steady air leakage from muffler. | Damaged air valve | Replace, page 44. |

|

|

|

| Damaged piston | Replace, page 42. |

|

|

|

Air leakage from front air valve. | Damaged air valve | Replace, page 44. |

|

|

|

Component B (resin) leak from fluid | Worn rear rod seal. | Adjust Rear Rod Seal, page 29. |

housing. |

|

|

|

|

|

309856P | 31 |